Monitoring the weld is essential to efficient automatic welding. Otherwise, quality and productivity suffer, and waste costs escalate.

Having a view of the weld tip and its immediate environment is critical in ensuring that the weld tip is properly aligned with the pieces it’s welding, that the weld seam and pool are properly aligned and formed during the welding process, and that a number of material inputs (e.g., welding wire or gas) are all being fed at ideal speeds.

Yet putting operators near enough to the weld to view the process is often unsafe due to the heat, smoke, spatter, and UV radiation commonly found in weld environments. Sometimes it’s actually physically impossible to get an operator close enough to view the features needed. Besides, the filters in welding helmets don’t allow for sufficient vision to see the weld arc and its background environment.

Weld Cameras provide the solution to this dilemma. These cameras are industrially hardened cameras that can be placed in position to acquire live video from most open arc welding process, including TIG, MIG, Plasma, and Laser.

Using a Weld Camera to monitor a semi-automatic or fully automatic welding process enables operators to see the process remotely—keeping operators safe, reducing costs associated with workplace injuries, and improving employee morale and retention.

A Weld Camera can also allow for the welding environment to be seen when no open arc weld is present, with minimum changes to the camera setup parameters.

Standard Cameras Limited in Weld Viewing

Unfortunately, use of Weld Cameras has been hampered by inadequate equipment. The traditional approach has been to use standard “off-the-shelf” cameras, with the addition of special filters and/or digitization software techniques to achieve an improved weld image.

But such customization of standard cameras hasn’t resulted in reliable image quality of the welding process. Due to over- or underexposure of some portions of the weld environment, valuable content continues to be lost in the images, masking much-needed, detailed information about the welding environment.

Consequently, using standard cameras, the welding operator is unable to maximize the performance of the welding process.

Wide Dynamic Range Images

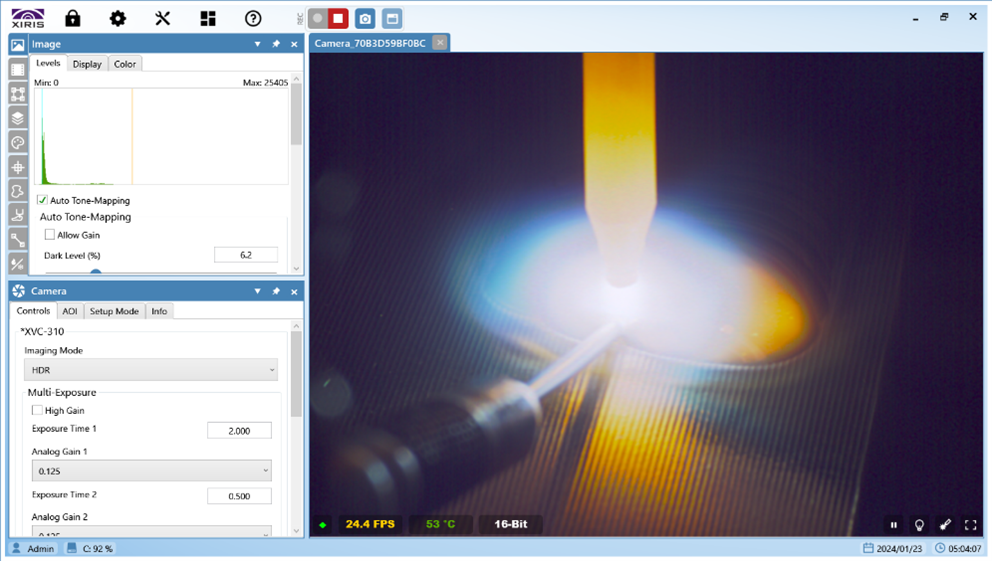

To overcome the limitations of standard cameras, High Dynamic Range imaging technology is now available on Weld Cameras.

A High Dynamic Range image can overcome the visual monitoring challenges created by having to image a large dynamic range that extends from the very bright light source of an open weld arc to the dark area of its immediate environment.

Ideally, a Weld Camera should be able to electronically create a High Dynamic Range image right in the camera head, removing unnecessary light wavelengths and pixel saturation in order to clearly see the detail of the weld tip, as well as its darker environment.

With this technology, the Weld Camera can help to maximize the performance of most automated welding systems by providing real time views of the torch, weld areas, and surrounding material to help maximize arc on time, seam alignment, and other welding parameters.