Laser welding offers several advantages over conventional TIG or Plasma welding processes especially for difficult to weld materials where lightweight, high strength and corrosion resistance is needed.

Advantages include:

- High welding speed (up to 60 m / min), especially for thin walled material

- Produces a small Heat Affected Zone (HAZ) with less joint distortion

- Favourable fine grain structure of the weld bead with excellent material properties

- Very clean welding process with minimal spatter, small weld beads and high precision

- Well suited for welding exotic alloys of stainless steel, titanium and aluminum

Since laser welding is fast and generates a small melt pool, it requires precise positioning (typically within a few tenths of a mm) relative to the weld seam. Even small misalignments in the fit-up can lead to weld defects in the tube such as lack of sidewall fusion or porosity.

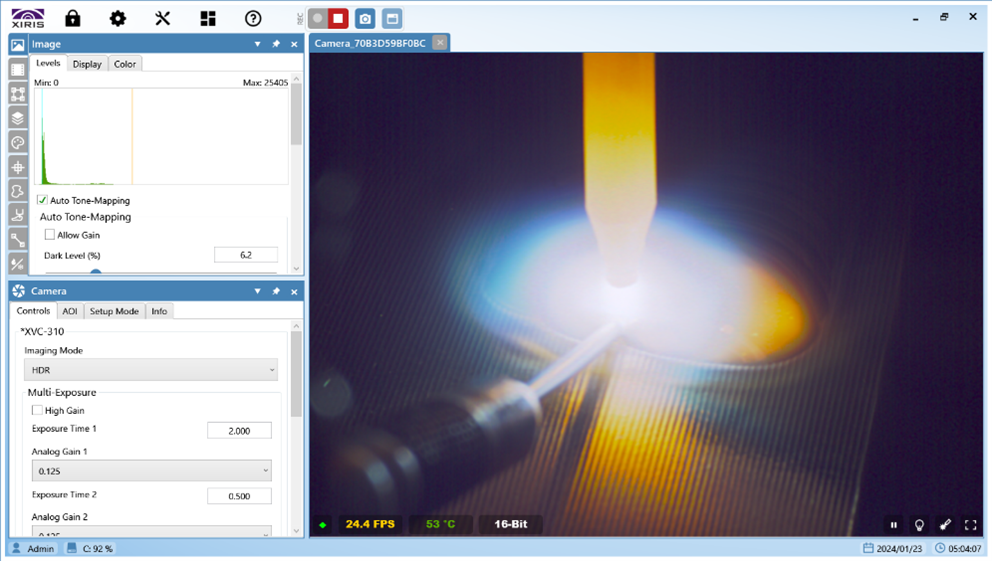

The Xiris SeamMonitor™ for laser welding has been specifically developed for seam tracking of laser welded seams. The SeamMonitor™ software in combination with a Xiris High Dynamic Range (HDR) weld camera enables real-time monitoring of the melt pool size and shape, and the relative location of the weld seam to the laser keyhole spot using machine vision technology.

Video of the User Interface of the SeamMonitorTM for a Laser Welding Process

The SeamMonitor™ system includes a Xiris open arc weld camera, industrial HMI controller, SeamMonitor™ software, optics and interfaces to integrate with other automation devices. It can be added to any laser welding process, either mounted off-axis to the laser beam, or on-axis through a suitable laser beam delivery camera port. Regardless as to how the camera is mounted, the SeamMonitor™ can help align the laser before welding, and monitor the laser welding process and track the seam during the welding process. All parameters and images can be recorded for process monitoring and quality assurance based on the set-up parameters and defined warning limits.

The SeamMonitor™ provides a powerful way to manually monitor the laser welding process while automatically measuring the laser keyhole-to-seam alignment and perform spot size.

Contact Xiris sales to see how our products can enhance your unique process.