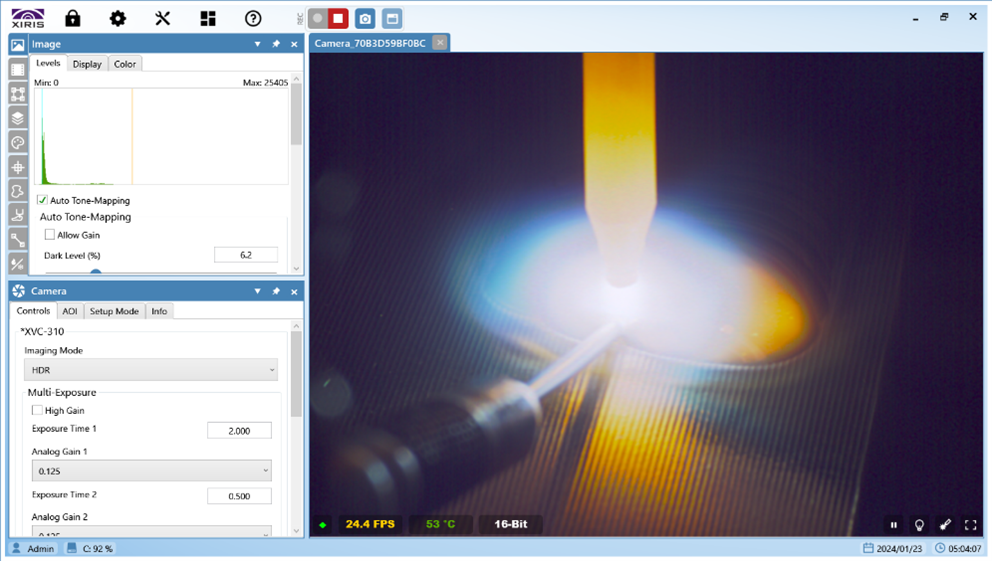

Most non-Autogenous welding processes use an external filler wire that is added to the process to help fill a large weld gap or provide a wide cladding area. The type of wire, size, metallurgical properties, type of coring, feed speed and angle are just some of the process parameters fabricators want to monitor to ensure their welding process is proven. But how to do it? A number of welding researchers have turned to the Xiris XVC-1000 Weld camera to get better images of their welding process to understand exactly what is happening

For example, using a Xiris XVC-1000 Weld camera can help researchers monitor key features of any filler wire feeding process:

1) Analyze how well the filler wire withstands its feeding process through a variety of welding processes such as high speed travel and side to side weaving processes:

High speed wire feed causes an inconsistent start, throwing pieces of wire

2) Monitor how well the wire is positioned relative to the weld:

Wire feed walking off center

3) Monitor how well the wire is being fed and if there is any damage to the wire during feeding

Wire damage is clearly evident

4) Monitor the timing of the wire feeding. This is particularly important during welds of short duration such as laser welding where it is important to analyze the timing of the wire delivery relative to the weld process. In the example shown below, a frame-by-frame analysis was done to observe the timing and interactions between the laser, wire feed, and robot positioning:

The wire touches the plate early

The laser turns on at the proper time; the wire feed has not yet started

The wire feed finally catches up

The wire feed turns off and the head begins to rise with the laser still on

The above examples are just some of the areas where a weld camera can be used to help with the process and product development of what type of wire and what parameters to use for specific types of non-autogenous welding.

For more information on how Xiris Weld Cameras can augment your R&D processes, visit Xiris.com

Sign up to receive our Weld Video of the Month