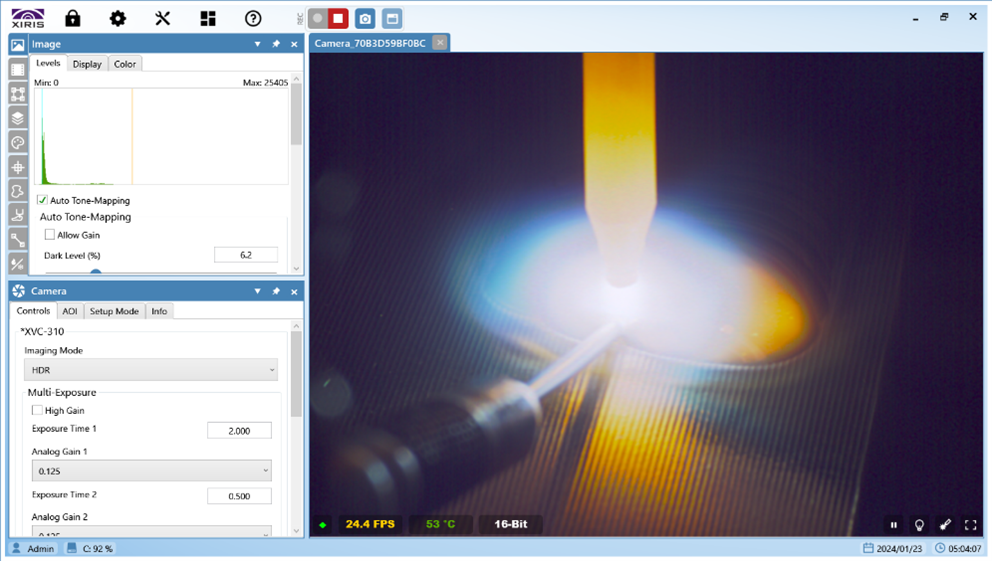

Each type of welding has a unique sound. Sometimes that sound can signify problems. Other times it tells the operator that everything is going exactly right. Xiris has now added audio monitoring to our industry-leading weld cameras with the Xiris WeldMic™ welding microphone. This innovative system gives welders a new tool to monitor and improve their operations.

However, it often takes years of experience to be able to distinguish the slight differences in sound that separate a good weld from a bad one. And if you’re new to welding or you’ve not been monitoring by sound before, how do you know what to listen for?

Make sure to turn your volume up to hear the sounds of GMAW in this weld video.

Today, we’re looking at GMAW, or MIG welding, and sharing the various sounds you may hear and what they mean.

- Frying Bacon: This is the most common description for what GMAW sounds like. The torch will sizzle, with the occasional pop. This usually means that your welder is set up properly and you are laying a quality bead.

- Popcorn Popping: If your welding sounds more like popcorn than bacon, with lots of snapping and popping, this may signify that your wire speed is too fast. “The wire is hitting the surface and not melting into the metal fully, creating a weak and dangerous weld.”1

- Hissing, as though gas is leaking: Often means too slow of a wire speed. This is also a weak, unsafe weld.1

- Popping and Hissing: This usually signifies a problem with the shielding gas. You will also see excessive sparks and slag, and pores in the finished weld. Check that the gas is on, there is gas in the tank and the tank pressure is correct.1

- Irregular: Another issue that can be identified by sound is wire stickout. If your stickout is too long, the arc may sound irregular – constantly changing in pitch and/or volume.2

The voltage and current setting on your welder, as well as the metal that you are welding, all affect the sound of the arc in GMAW.3 For example, stainless steel welding uses three different approaches: dip transfer, globular transfer or spray arc. Each of these techniques has a different sound, as the arc moves from low power to high through the metal transfer cycle.4

In dip transfer (low amperage welding, which is ideal for thinner materials), you hear a fast crackling—the coveted bacon sound. Globular transfer, which is not often used, makes an uneven, splattering sound, with occasional hisses. Spray transfer has a consistent hissing sound as the hot metal transfers to the parent material in a steady stream.

It is important to learn your equipment, understand your materials and experiment with different settings. Monitor the sound and appearance of the arc and critically evaluate the quality of your welds. Soon you will know what to listen for.

To learn more about the Xiris WeldMic™, watch a recording of our webinar Improving Welding Automation Using Audio Monitoring or request to talk to one of our experts.

Follow Xiris on social media for regular updates and welding videos!

Sources:

1https://garage.eastwood.com/eastwood-chatter/listen-to-your-mig/

2https://www.millerwelds.com/resources/article-library/mig-welding-the-basics-for-mild-steel

3https://forum.millerwelds.com/forum/welding-discussions/4179-mig-welding-sound

4https://www.theshedmag.co.nz/home/2018/7/8/tackling-stainless-a-guide-to-stainless-steel-welding