Modern manufacturing requires fabrication processes that use automated welding across numerous applications and materials. But the welding industry is having difficulty attracting people into the profession—in large part because welding is perceived as a dirty, dangerous, and unhealthy type of work.

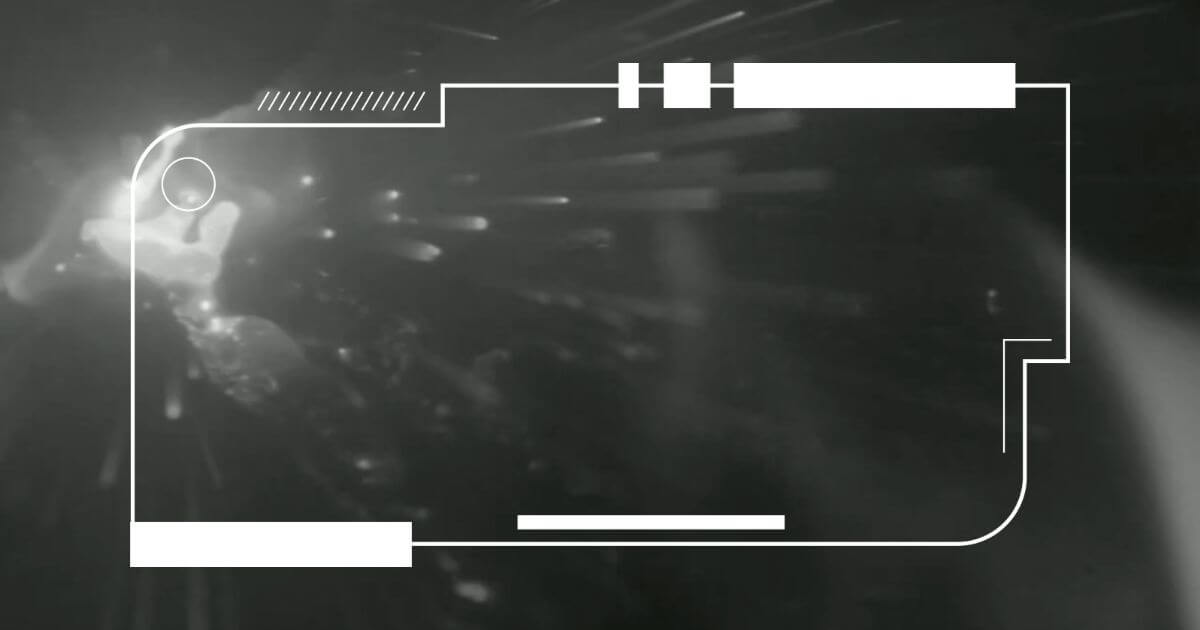

This perception isn’t wrong in cases where the monitoring of the automated welding process is still being done by operators standing close enough to see the weld.

However, using a Weld Camera, operators can monitor the weld remotely, avoiding the many dangers of being close to the weld—making the job considerably more desirable.

Creating a Safer Work Environment

Remote monitoring prevents operators from being exposed to welding smoke, which is a mixture of very fine particles (fumes) and gases derived from a combination of the base metal, filler metals, welding rods, fluxes, and coverings. Operators in the same area where the welding is being done are continuously breathing in the toxic substances in this smoke, which is indisputably harmful to their health.

Other health risks that remote monitoring removes from operators include:

- Proximity to large, potentially dangerous automated machinery.

- Vision damage from exposure to the extremely bright light of the open arc.

- Possible burns due to hot weld spatter, sparks, and flying particles.

- Hearing loss from the high noise levels of the machinery and welding process.

- Repetitive stress injuries when there is a continuous weld bead required.

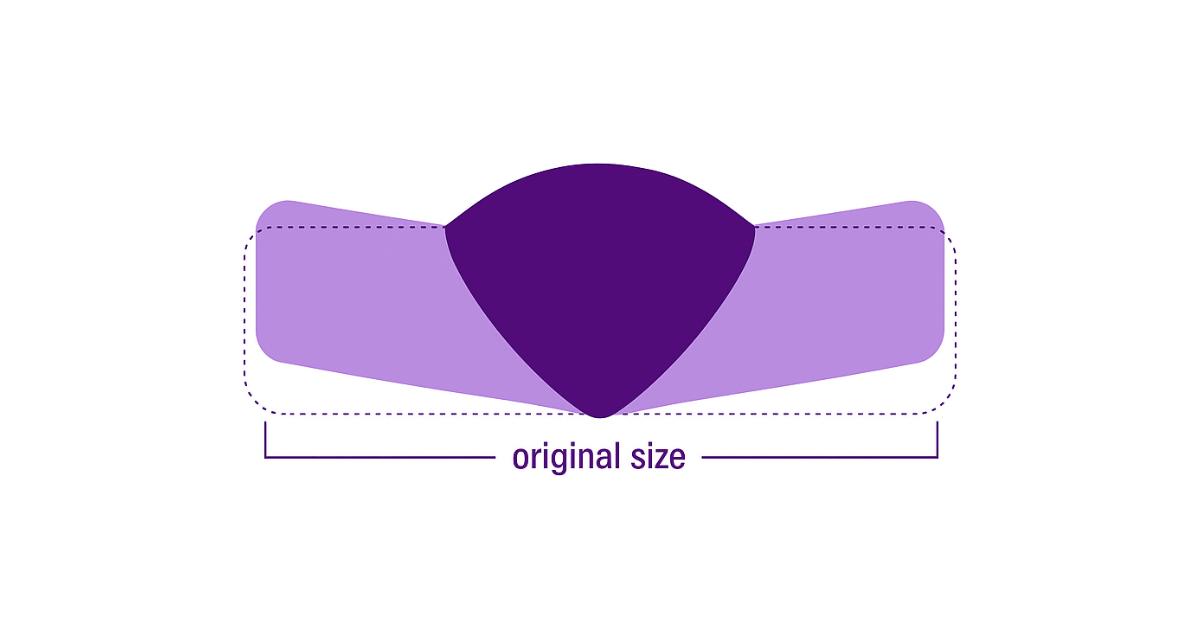

- Having to work up high (e.g., for shipbuilding or large-diameter pressure vessels).

- Having to work in tight spaces (e.g., narrow pipes for pipe cladding).

Pleasing Operators

The ability to attract and retain skilled welders is a key competitive advantage, which will only become more important as aging welders retire. (The average age of welders in the United States is now more than 50 years old!)

Anything that can be done to make the work environment more comfortable will help in this attraction and retention—and enabling remote monitoring with a Weld Camera tops the list of actions you can take to make welders more-satisfied with their working conditions. Having to work in a noisy, hot environment is obviously a turn-off when people consider careers, but with a Weld Camera, operators can work in relative comfort and safety.

Simply freeing welders from having to don welding helmets and protective clothing each time they monitor a weld can do wonders for their morale. Safety will rightly be a primary concern of welders, but the importance of comfort shouldn’t be underestimated.

Conclusion

Creating a safer, more-comfortable work environment is only one of the major advantages of Weld Cameras—they also significantly improve productivity and quality. But the crucial nature of creating better working conditions shouldn’t be overlooked, as it often is because it’s less quantifiable and tangible than productivity or quality.

In fact, upgrading the work environment goes hand in hand with greater operational efficiency and better quality. Morale is an important component of improvement in both areas, as is the reduction of operator fatigue, both mental and physical.

And because a more-appealing work environment will help attract younger and more-desirable operators, the transformation made possible with Weld Cameras will continue to pay dividends for years to come.