Welding Defects Guide: Types, Causes and Prevention

Welding defects are an inevitable challenge in welding processes, and understanding them is essential for ensuring the quality and safety of welded structures. This comprehensive guide provides an in-depth analysis of weld defects, detailing types, causes, prevention methods, and modern detection techniques such as non-destructive testing (NDT) methods like Xiris Weld Cameras. It equips you with the knowledge to optimize welding processes, minimize errors, and improve overall weld quality.

What Are Welding Defects?

Weld defects, or imperfections, are unwanted irregularities found in welds that can compromise the structural integrity and aesthetic quality of the welded piece. These defects, ranging from visible distortions to internal flaws, stem from various causes such as technique, material selection, and environmental conditions, and are often detected using non-destructive evaluation (NDE) methods or confirmed through destructive testing during failure analysis.

Understanding each defect and its potential solutions can greatly improve the quality of welding projects, making this knowledge essential for any welder or industry professional.

Categories of Welding Defects

Weld defects are typically classified into distinct categories, each reflecting specific aspects of the welding process that directly impact joint integrity and quality. This article will focus on three primary categories: dimensional imperfections, discontinuities, and surface defects, which arise as a result of welding parameters, application techniques, and process control.

Dimensional imperfections

Dimensional imperfections refer to issues in the shape or size of the weld bead, which can impact the weld’s structural integrity and durability. These defects often result from incorrect welding techniques or improper filler metal application, leading to weak joints or excessive material on the weld.

| Common Defects | Description |

|---|---|

| Under filled | Occurs when the weld bead lacks sufficient filler metal, resulting in weak joints. |

| Undercut | A groove at the weld toe that reduces the cross-sectional thickness of the base metal. |

| Overlap | Excess weld metal flows beyond the edge without bonding with the base metal. |

| Excess reinforcement | Too much filler metal on the weld bead, increasing the risk of cracking under stress. |

| Burn through | Results from excessive heat, causing the weld to penetrate through the base material. |

Discontinuities

Across different welding processes,

discontinuities are imperfections that interrupt the uniformity of the weld, creating areas of weakness that may compromise the welded structure. These defects can result from poor welding practices or environmental factors during the welding process.

| Common Defects | Description |

|---|---|

| Poor penetration | Occurs when the weld does not penetrate deeply into the base material, leading to weak bonds. |

| Lack of fusion | Failure of the weld metal to properly bond with the base metal, resulting in weak joints. |

| Cracks | Fractures that occur within or on the surface of the weld, potentially spreading and weakening the weld. |

| Slag inclusions | Entrapment of flux or slag particles within the weld metal, leading to weak spots and potential crack initiation. |

Surface Defects

Surface defects refer to imperfections that appear on the weld's surface, impacting both its appearance and, potentially, its structural integrity. These defects often arise from issues like contamination, rapid cooling, or inconsistent welding techniques. Surface defects can weaken the weld by creating stress concentration points or by allowing external elements to penetrate, but they can be identified through non-destructive visual inspection and advanced NDT methods.

| Common Defects | Description |

|---|---|

| Spatter | Small metal droplets that adhere to the surface around the weld, affecting appearance and quality. |

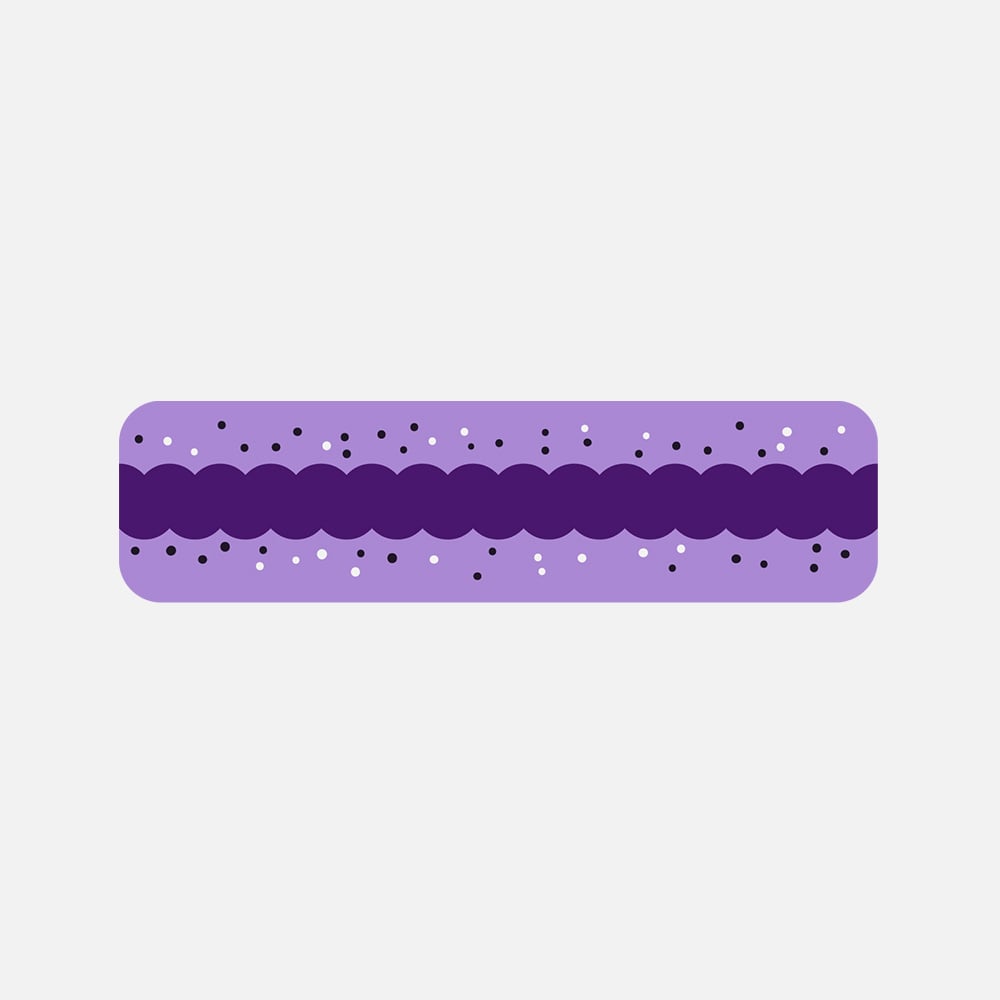

| Porosity | Gas bubbles trapped within the weld, creating weak spots and reducing strength. |

Metallurgical Defects

Imperfections related to the material properties and structural composition of the weld metal. These issues often arise due to improper heat treatment, rapid cooling, or variations in the composition of the weld and base metals. Metallurgical defects can weaken the weld by creating areas with different hardness, brittleness, or strength, leading to potential failure under stress. They may also affect the weld's resistance to corrosion or impact, depending on the environment and the welding process.

| Common Defects | Description |

|---|---|

| Segregation | Uneven distribution of alloying elements within the weld, causing inconsistent mechanical properties. |

| Microcracks | Small fissures within the weld metal that can lead to material failure under stress. |

15 Common Types of Weld Defects with Images and Videos

1. Underfill

Underfill is a dimensional defect where the weld metal surface is below the adjacent surface of the base metal. It appears as a groove or channel in the weld face, indicating that the joint has not been filled with a sufficient amount of filler material. This reduces the weld’s cross-sectional area and can significantly weaken the joint.

The reduced weld volume directly impacts the joint’s load distribution, making it vulnerable in applications with dynamic or concentrated stress points. Underfill welds often require rework in industrial settings, where precision and safety are paramount. The concave profile also creates a notch effect that can serve as a fatigue crack initiation site under cyclic loading.

Underfill is typically caused by a combination of incorrect welding parameters. The most common causes include:

-

Low filler metal input, where insufficient filler metal is deposited during welding.

-

Low heat input, which creates a concave, undersized weld bead.

-

Inappropriate travel speed, which fails to allow adequate material deposition. In robotic welding, a programming error in the wire feed rate or travel speed can also produce consistent underfill across an entire production run.

-

Optimizing the balance between deposition rate and travel speed.

-

Increase filler metal deposition to create an adequately sized weld bead and avoid concave profiles.

-

Adjust heat input to enable full coverage across the joint and maintain a steady travel speed for uniformity.

-

Apply multiple passes if needed to achieve the required thickness for load-bearing joints.

-

In automated systems, verifying the programmed parameters against the actual joint geometry before production is essential.

Underfill welding defect images

Video: Plasma - Robotic Assembly - Inconel (Turbine Fuel Injector) - Underfill Defect

This footage captures plasma arc welding (PAW) applied in a robotic setup for an Inconel turbine fuel injector. The process exhibits high thermal efficiency but presents an underfill defect. Such defects could impact fatigue resistance and necessitate parameter optimization for improved consistency.

Video: GMAW Defect – Butt Weld – Carbon Steel – Underfill

This footage captures gas metal arc welding (GMAW) applied for a butt weld joint with V-groove. Due to inadequate and increasing groove gap, the weld pool sinks and does not fill the groove sufficiently. As a result, an underfill defect occurs.

Frequently Asked Questions About Underfill

Underfill can occur in any welding process, but it is particularly common in high-speed automated processes like GMAW and SAW if the parameters are not perfectly calibrated to the travel speed and joint design. It is also frequently seen in plasma arc welding (PAW) of turbine components and in orbital TIG welding of pipes where access is limited.

Underfill is when the entire weld face is below the base metal surface, indicating insufficient filler material in the joint. Undercut is a sharp groove melted into the base metal at the toe of the weld, which is a stress concentration point, even if the weld face itself is properly filled. Both are dimensional defects, but they occur in different locations and have different root causes.

Most welding codes and standards set limits on the amount of underfill that is acceptable. For example, AWS D1.1 (Structural Welding Code – Steel) specifies maximum allowable underfill depths depending on the thickness of the material and the type of loading (static vs. cyclic). ISO 5817 also classifies underfill by quality levels (B, C, D) with specific dimensional tolerances.

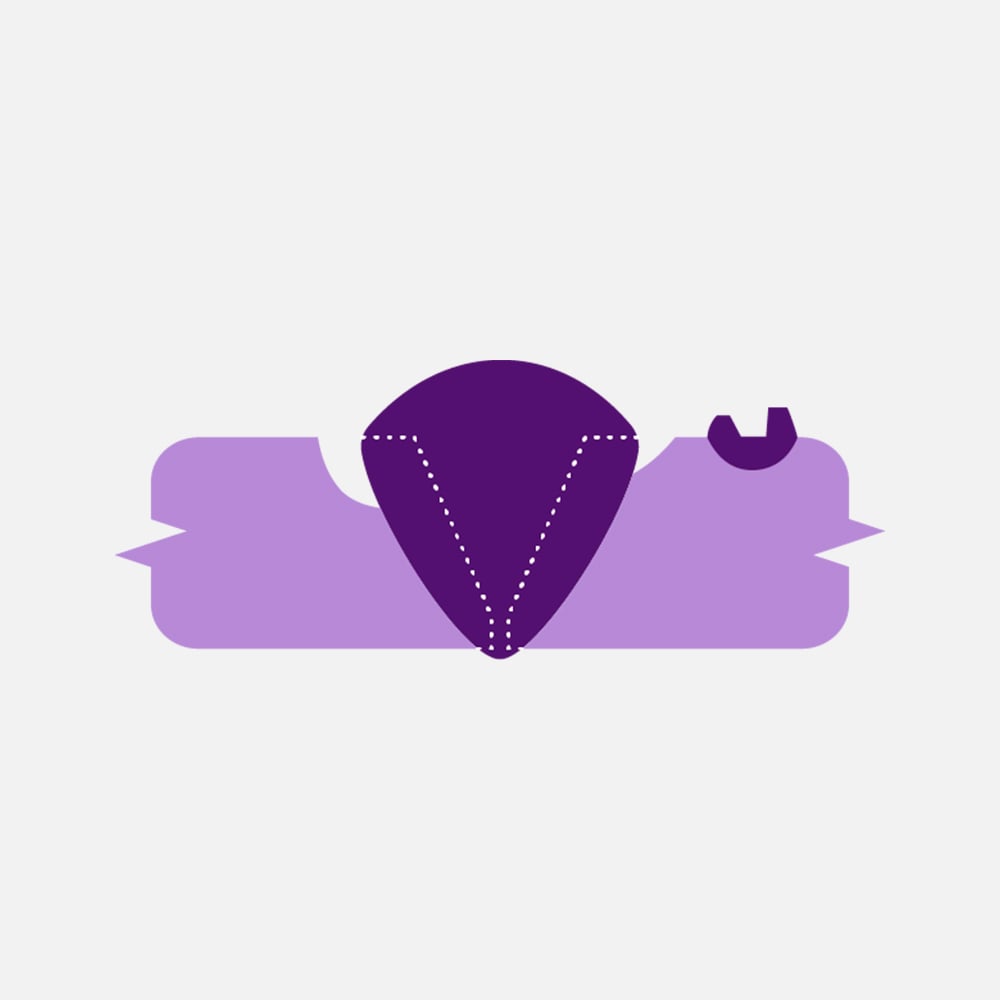

2. Undercut

Undercut is a groove melted into the base metal adjacent to the weld toe or weld root that is left unfilled by weld metal. This defect creates a sharp notch, which acts as a stress concentrator, significantly reducing the fatigue strength of the weld and making it a critical flaw in load-bearing structures.

The reduction in cross-sectional area acts as a stress concentrator, creating a vulnerable point susceptible to fatigue failure. In load-bearing structures, undercuts can significantly compromise the weld’s ability to withstand cyclic loading, leading to premature cracking. Even a small undercut of 0.5 mm can reduce the fatigue life of a welded joint by a significant margin.

Undercut is primarily caused by excessive heat input or improper technique. Specific causes include:

-

High current that erodes the base metal edges.

-

High travel speed that limits fusion time, leaving exposed edges.

-

Incorrect electrode angle that directs heat towards edges without bonding. In GMAW spray transfer mode, the high arc pressure can also push molten metal away from the toes.

Prevention involves careful control of welding parameters. Lower the welding current to avoid excessive heat at the edges of the weld. Reduce travel speed to allow more bonding time. Maintain a 5–15° electrode angle for even heat distribution. Use a weave technique to fill the edges effectively, especially on vertical welds. In multi-pass welds, ensure each pass overlaps the previous one sufficiently to cover the toes.

Learn more about Undercut Defect

Monitoring Tube and Pipe Production to Find UNDERCUT Defects

Undercut welding defect images

Video: GMAW Defect – Fillet Weld – Carbon Steel – Undercut

This footage shows the formation of an undercut defect in gas metal arc welding (GMAW) of a fillet weld. Due to inadequately high wire feed rate and travel speed, the excessive arc pressure in the spray transfer mode leads to the formation of an undercut defect.

Video: GMAW Defect – Lap joint – Carbon Steel – Undercut

This footage shows the formation of an undercut defect in gas metal arc welding (GMAW) of a lap joint. Too high wire feed rate and travel speed lead to the formation of an undercut defect on the edge of the top plate.

Frequently Asked Questions About Undercut

Real-time detection is highly effective for undercut. By using a Xiris Weld Camera, operators can clearly see the weld pool and the edges of the joint. The high-dynamic-range image allows them to spot the formation of a groove at the weld toe instantly and adjust their technique or parameters to correct the issue on the fly. For more information, see our detailed article on Welding Undercut: Causes, Detection, and Prevention.

Minor undercut can sometimes be repaired by lightly grinding the area to blend the notch into the base metal, but this reduces the material thickness. More severe undercut requires cleaning the area and applying a small, precise weld bead (a “stringer bead”) to fill the groove, taking care not to create a new undercut in the process.

Undercut is particularly common in vertical and overhead welding positions, where gravity works against the welder, pulling the molten metal away from the upper edge of the joint. This requires even more careful control of technique and parameters. Horizontal fillet welds are also prone to undercut on the upper plate.

Yes, an incorrect shielding gas or flow rate can affect arc stability and heat profile, contributing to undercut. For example, using 100% CO2 can result in a hotter, more forceful arc that is more prone to causing undercut compared to an Argon/CO2 blend. The gas composition directly influences the arc pressure and the fluidity of the weld pool.

External undercut (also called crown undercut) occurs at the toe of the weld on the face side and is visible during inspection. Internal undercut (or root undercut) occurs at the root of the weld and is typically only detectable by radiographic or ultrasonic testing. Both types are stress concentrators, but root undercut can be more dangerous as it is hidden.

Acceptance criteria vary by code and application. AWS D1.1 limits undercut to 1/32 in. (1 mm) for members subject to cyclic loading and 1/16 in. (2 mm) for statically loaded members. ASME Section IX and ISO 5817 have their own limits based on quality levels. In critical applications like pressure vessels and aerospace, zero undercut is often the requirement.

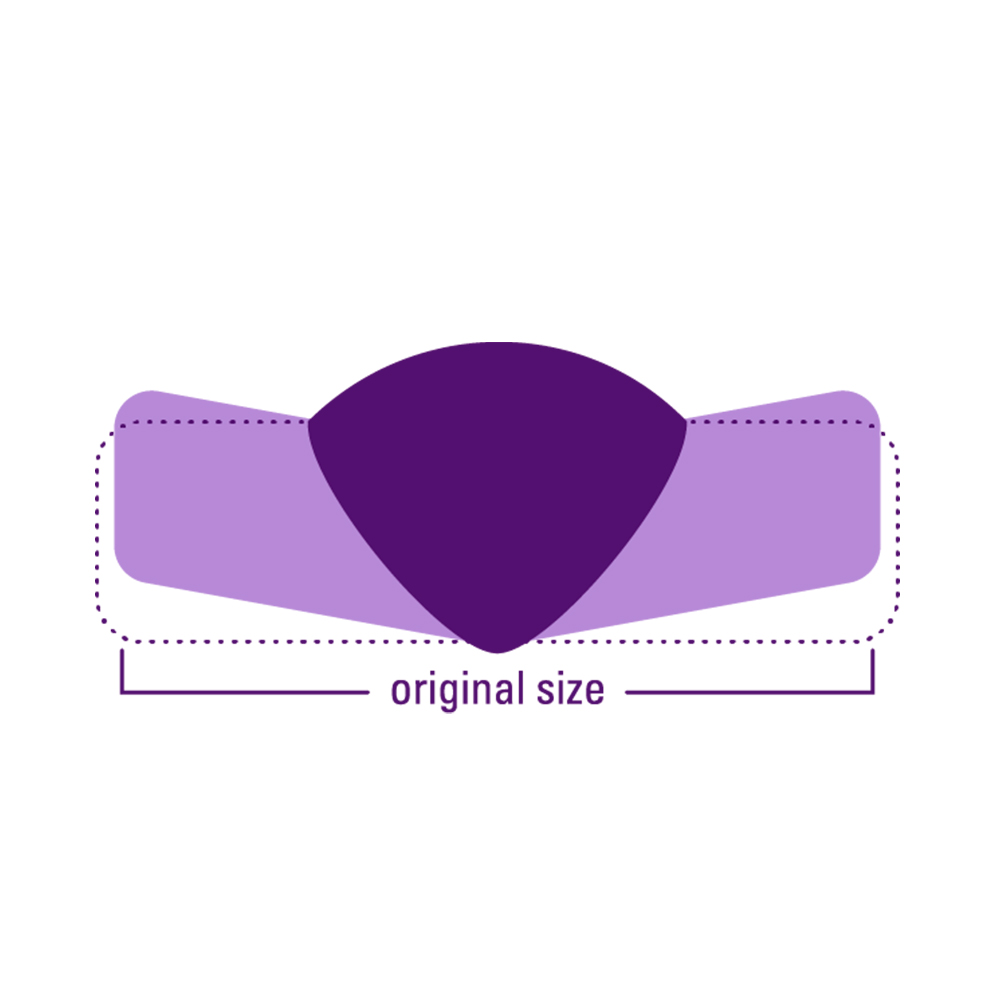

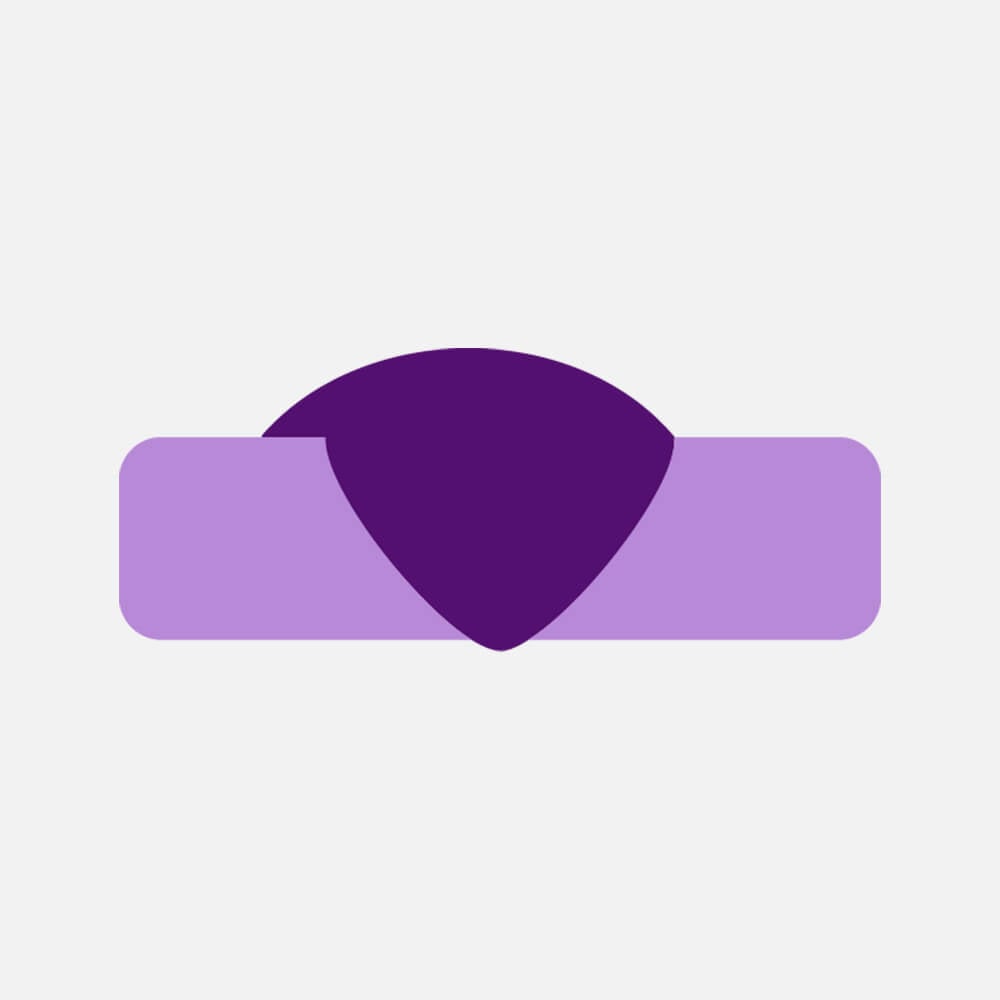

3. Lack of penetration

Lack of penetration, or incomplete penetration, occurs when the weld metal fails to extend through the full thickness of the joint. In a butt joint, this means the weld metal does not reach the root of the joint, leaving an un-fused area that severely compromises the weld’s strength.

Incomplete penetration leaves unfused areas within the joint that act as stress concentrators. These hidden discontinuities compromise the joint’s ability to handle tensile and bending loads and can lead to crack initiation under cyclic stress. In critical applications, this defect demands full rework to ensure structural reliability.

This defect is often a result of insufficient heat input or improper joint setup. Key causes include:

-

Low current settings that fail to reach the required joint depth

-

High travel speed that reduces the arc’s ability to achieve full penetration

-

Improper joint fit-up, such as a misaligned joint or a root gap that is too small.

Ensure proper joint preparation with an adequate root opening. Use a higher welding current and a slower travel speed to increase heat input and allow the arc to penetrate the root. Proper cleaning of the joint is also essential. For automated processes, precise joint tracking is critical to maintain consistent torch-to-seam alignment.

Lack of penetration welding defect images

Frequently Asked Questions About Penetration

In automated welding, ensuring the torch is perfectly aligned with the weld seam is crucial for achieving consistent penetration. The Xiris SeamMonitor tool within WeldStudio™ 3 Pro can be used to track the seam in real-time, ensuring the arc is always directed at the root of the joint, which is fundamental to preventing lack of penetration.

Since lack of penetration is an internal defect, it is not visible from the surface. It must be detected using non-destructive testing (NDT) methods such as radiographic testing (X-ray), which shows the unfused root as a dark line, or ultrasonic testing, which detects the discontinuity as a reflected signal.

Lack of penetration is when the weld fails to reach the root of the joint — it’s a depth issue. Lack of fusion is when the weld metal fails to fuse with the sidewalls of the joint or with a previous weld pass — it’s a bonding issue. Both are serious internal defects, but they occur in different locations within the joint.

Absolutely. A joint with a very narrow groove angle, a large root face (the flat part at the bottom of the groove), or an insufficient root gap can physically prevent the arc from reaching and melting the root of the joint, making complete penetration impossible regardless of the parameters used. Proper joint design is the first line of defense.

Yes. Processes with lower heat input, such as short-circuit GMAW, are more prone to lack of penetration on thicker materials. Conversely, high-energy processes like SAW and plasma arc welding are less susceptible but can still produce this defect if the joint fit-up is incorrect.

Repair typically involves back-gouging the root of the weld from the opposite side (if accessible) to remove the unfused area, then re-welding. If back-gouging is not possible, the entire weld may need to be removed and re-done. This is one of the most costly defects to repair.

4. Lack of fusion

Lack of fusion is the poor adhesion of the weld bead to the base metal (sidewall fusion) or to a previous weld bead in a multi-pass weld (inter-run fusion). It creates a gap where the metals have not been successfully joined, acting as a critical stress riser and a potential failure point.

Lack of fusion weakens the weld interface, rendering it susceptible to delamination and cracking under stress. In critical applications, such as bridge construction, pressure vessels, or structural frameworks, this flaw necessitates strict inspection and rework protocols to ensure stability. It is considered a planar defect, which is more dangerous than a volumetric defect like porosity.

Common causes include:

-

Low current settings that limit the arc’s penetration capability.

-

Poor joint preparation that hinders the interaction of the materials.

-

Fast travel speed that reduces the heat exposure time necessary for melting.

-

An incorrect torch angle that directs the arc away from the sidewalls.

Raise current settings to achieve deeper penetration and complete bonding along the joint. Prepare joint surfaces by cleaning thoroughly to remove contaminants that can obstruct fusion. Reduce travel speed to give the weld pool enough time to melt and fuse properly. Ensure the torch angle directs the arc into the sidewalls of the joint.

Learn more about Lack of Fusion

Using Video and Audio to Help Detect Welding Defects

Lack of fusion welding defect images

Video: GMAW Defect – Lap joint – Carbon Steel – Lack of Fusion

This video captures gas metal arc welding (GMAW) of mild steel in a fillet weld. The weld surface was contaminated with aluminum powder traces that caused the lack of fusion defect in the bottom plate.

Frequently Asked Questions About Lack of Fusion

While internal lack of fusion requires NDT methods like ultrasonic testing, some forms can be detected by monitoring the weld pool’s behavior. Changes in the sound of the arc can also indicate a problem. The WeldMic™ feature in WeldStudio™ 3 Pro can capture these audio anomalies, while a Xiris Weld Camera allows an operator to see if the weld pool is properly wetting and fusing with the sidewalls of the joint.

Repairing lack of fusion requires removing the defective weld metal by grinding, gouging, or machining until sound metal is reached. The joint is then re-welded using a correct procedure and qualified welder. The repair area must be inspected again to confirm the defect has been eliminated.

Yes. If the weld pool is too large and sluggish (a “cold” pool), it may flow onto the sidewall without actually melting it, leading to a classic lack of fusion defect. This is often caused by low current or voltage settings combined with excessive wire feed.

Materials with high thermal conductivity, such as aluminum and copper, can be more susceptible to lack of fusion because the heat is quickly drawn away from the weld area, making it harder to maintain a molten pool that can fuse with the cold sidewalls. Stainless steels with oxide layers can also be problematic.

Sidewall lack of fusion occurs between the weld metal and the base metal at the groove face. Inter-run lack of fusion occurs between successive weld passes in a multi-pass weld, often due to inadequate inter-pass cleaning or insufficient remelting of the previous bead. Both are equally dangerous.

5. Spatter

Spatter refers to the small droplets of molten material that are ejected from the arc and land on the surrounding workpiece. While not always a structural defect, excessive spatter requires costly and time-consuming cleanup and can indicate an unstable welding process.

Beyond aesthetic concerns, spatter can affect component fit-up in assemblies and requires post-weld cleanup. While spatter does not directly weaken the weld, it can compromise the precision and surface finish required in high-quality manufacturing. In some cases, spatter can also damage sensitive nearby components or coatings.

Spatter is often caused by incorrect machine settings, such as:

-

Excessive current that expels metal particles from the weld pool.

-

Improper polarity that affects arc stability.

-

Insufficient shielding gas flow that results in scattered particles on the surface. A dirty or rusty workpiece can also increase spatter significantly.

To prevent spatter, optimize your welding parameters. Lower the voltage and current, shorten the arc length, and ensure you are using the correct shielding gas composition and flow rate for your material. Using a consistent wire feed and maintaining a proper torch angle are also key. Anti-spatter spray can be applied to the workpiece as an additional measure.

Learn more about Spatter Defect

8 Ways Weld Cameras Improve Productivity #2: Reduce Errors and Cut Costs

Poor Spatter welding defect images

Video: GMAW Defect - Manual - Tee Joint - High Spatter (3 Coupon Welds)

This video captures a manual GMAW process on a Tee joint, highlighting spatter formation across three coupon welds. Despite stable arc behavior, moderate spatter is observed, likely due to shielding gas turbulence or voltage fluctuations. The bead remains consistent, ensuring sufficient fusion. Process optimization may reduce spatter without compromising penetration.

SMAW - Bead on Flat Steel Plate - Trailing - Lots of Spatter - Monochrome

This video showcases a SMAW bead-on-plate weld using a trailing technique. High spatter levels and irregular bead consistency suggest unstable arc conditions, possibly due to excessive amperage or inconsistent electrode angle. Arc intensity is relatively high, which may contribute to excess metal expulsion. Optimizing parameters could enhance bead uniformity.

Frequently Asked Questions About Spatter

Spatter can be easily monitored in real-time. A Xiris Weld Camera provides a clear view of the arc and weld pool, allowing an operator to see the amount of spatter being generated and adjust parameters to minimize it. Additionally, the WeldMic™ can detect the distinct sound of spatter, providing another layer of process monitoring to help operators tune the process for maximum stability.

Yes, significantly. Short-circuit transfer mode is prone to spatter as the wire repeatedly touches the workpiece, causing small explosions. Spray transfer is much smoother with less spatter, but requires higher energy. Pulsed GMAW offers a good compromise, providing a stable arc with low spatter across a wide range of parameters.

Not necessarily a bad weld in terms of strength, but it is a sign of a poorly controlled or non-optimized welding process. Excessive spatter indicates instability that could also be causing other, more serious defects like porosity or lack of fusion.

The cost of spatter goes beyond the obvious cleanup time. It includes labor for grinding and removal, potential damage to the workpiece surface, consumption of anti-spatter products, and the risk of quality issues in painted or coated assemblies. In high-volume production, even small amounts of spatter per part can add up to significant costs.

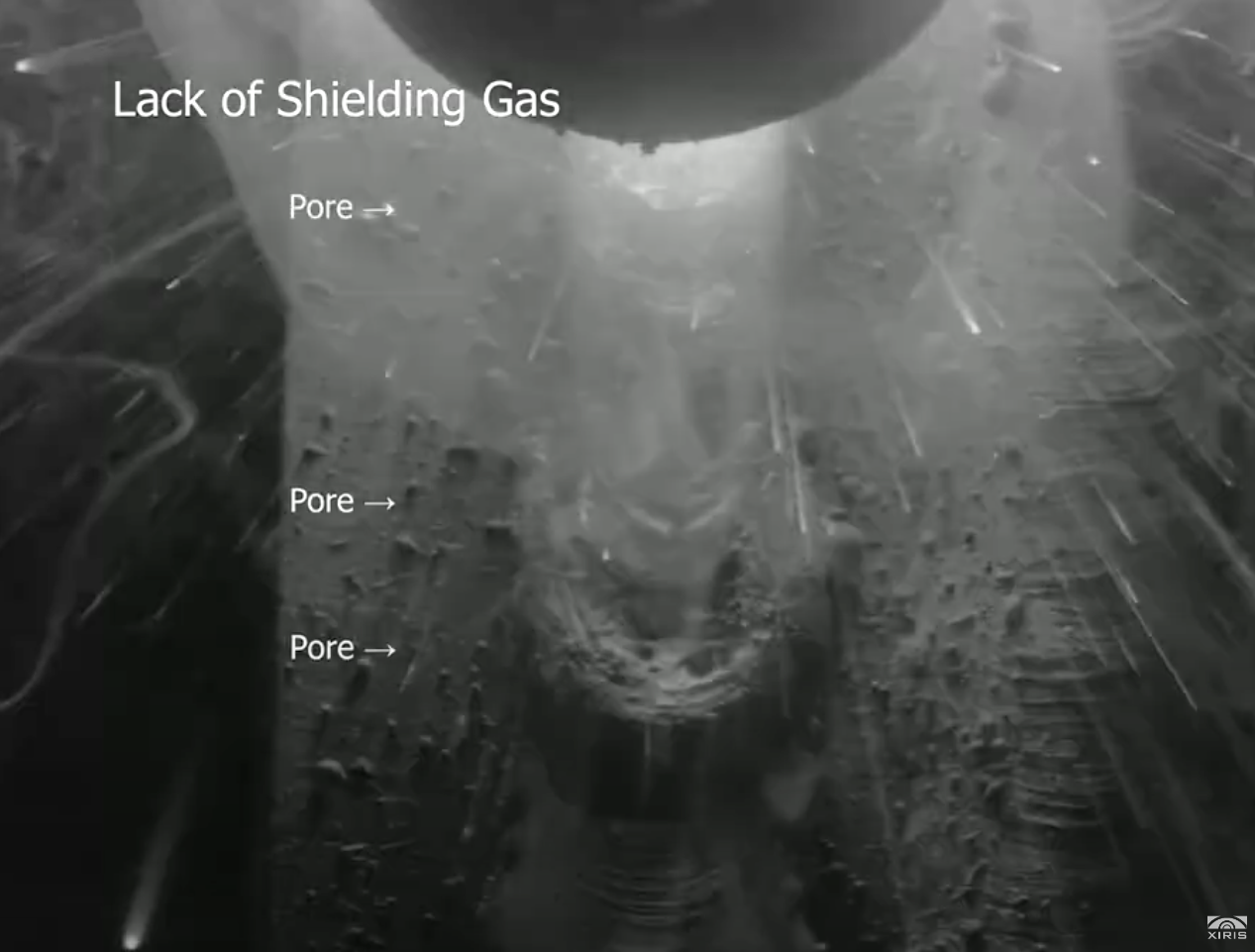

6. Porosity

Porosity is a contamination defect that occurs when gas becomes trapped and forms bubbles or voids within the solidifying weld metal. These pockets of gas can be clustered together, scattered throughout the weld, or aligned in a linear pattern, weakening the final joint.

Porosity reduces the weld’s density and strength, which is critical in pressurized environments. Applications in piping or pressurized vessels are particularly vulnerable, as porosity can lead to leaks and structural failures under operational stress. Porosity also reduces the effective cross-sectional area of the weld.

There are several types of porosity:

-

Distributed (scattered) porosity, where gas pores are spread throughout the weld.

-

Clustered porosity, where pores are grouped in a localized area.

-

Linear porosity, where pores form along a line, often at the weld root or between passes.

-

Piping (wormhole) porosity, where elongated gas tunnels form perpendicular to the weld surface.

The primary cause is the absorption of nitrogen, oxygen, or hydrogen into the molten weld pool. This can happen due to:

-

Contaminated base material with oxides, moisture, or oil.

-

Inadequate shielding gas flow that allows air and moisture to enter.

-

Moisture in filler material that releases gas during welding. Wind drafts that disrupt the shielding gas coverage are also a major cause.

Porosity welding defect images

GMAW Defect - Stainless Steel - Robotic Automotive - Porosity

The robotic GMAW process on stainless steel exhibits significant porosity defects, likely due to shielding gas inconsistencies, oxidation, or entrapped contaminants. The instability in bead formation suggests inadequate process control, emphasizing the need for optimized welding parameters and environmental shielding conditions to mitigate gas entrapment.

GMAW Defect - Short Circuit - Butt Weld - Trailing Side View - Porosity

This video captures a GMAW short-circuit process on a butt weld, filmed from a trailing side view. The welding arc is active, but porosity defects are consistently visible along the bead. These defects were caused by surface contamination in the middle section of the weld.

Frequently Asked Questions About Porosity

Prevention starts with cleanliness. Clean the base metal thoroughly to eliminate oils, rust, and dirt. Store filler materials in a dry area to avoid moisture absorption; preheat materials if necessary. Ensure proper shielding gas flow (typically 15–20 CFH for GMAW) and avoid drafts in the work area. For SMAW, use low-hydrogen electrodes stored in a rod oven.

While severe porosity is visible on the surface, internal porosity is harder to detect and requires radiographic testing. However, the conditions that cause porosity often create an unstable arc. The WeldMic™ feature in WeldStudio™ 3 Pro can detect the subtle audio changes associated with arc instability or gas flow interruptions that lead to porosity, alerting an operator to a potential problem before it becomes severe. For more details, see our article on Porosity in Welding: Causes, Types, and How to Detect It.

If porosity is localized, the affected area can be ground out and re-welded. For widespread porosity, the entire weld may need to be removed and re-done after addressing the root cause (e.g., fixing gas flow, cleaning the material). The key is to identify and eliminate the source of contamination before re-welding.

Yes, wind is one of the most common causes of porosity in outdoor or semi-outdoor welding environments. Even a light breeze of 5 mph can disrupt the shielding gas coverage, allowing atmospheric gases to contaminate the weld pool. Windscreens or shelters should be used when welding in exposed areas.

Porosity refers to multiple small gas voids distributed within the weld. A gas pocket (or blowhole) is a single, larger cavity formed by trapped gas. Both are caused by similar mechanisms, but gas pockets are typically more localized and can be more detrimental to the weld’s integrity due to their size.

7. Overlap

Overlap is a defect where the weld metal protrudes over the surface of the base metal at the toe of the weld but does not fuse to it. It’s often a sign of incorrect technique or parameters and creates a mechanical notch similar to an undercut.

Overlaps compromise the weld surface, reducing its corrosion resistance and creating potential points of weakness. This flaw is particularly detrimental in applications that require strict surface integrity, as it undermines the weld’s longevity and resistance to environmental degradation.

Overlap is typically caused by:

-

High welding speed that allows molten metal to flow onto the surface without bonding.

-

Excessive filler metal deposited without enough fusion control

-

Inadequate heat distribution that prevents bonding with the base metal. An incorrect torch angle can also push molten metal onto the cold base plate.

Maintain proper heat input to ensure the weld metal fuses with the base metal. Avoid excessive filler metal deposition and use consistent wire feed or rod addition. Keep a correct electrode or torch angle to guide the molten metal into the joint instead of onto the surface. Adjusting the travel speed to match the deposition rate is key.

Poor Overlap welding defect images

Frequently Asked Questions About Overlap

Overlap is a surface defect that is readily visible. Using a Xiris Weld Camera, an operator can monitor the weld bead profile in real-time. The camera’s clear view allows the operator to see if the weld pool is flowing correctly and fusing with the base metal, or if it is rolling over the edge, enabling immediate correction of travel speed or angle.

Overlap and cold lap are very similar defects. Both involve weld metal flowing over the base metal without fusing. The term “overlap” is more commonly used in codes and standards, while “cold lap” emphasizes the thermal cause (insufficient heat for fusion). In practice, they are often used interchangeably.

Yes. The overlapping metal must be removed by grinding, and if necessary, the area is re-welded with correct parameters to ensure proper fusion at the toes. Simply grinding the overlap smooth is not sufficient if the underlying metal is not fused.

Yes. Most welding codes consider overlap a rejectable defect because the unfused metal at the toe acts as a crack initiator. It is classified as a lack of fusion defect at the weld toe and must be repaired to meet quality requirements.

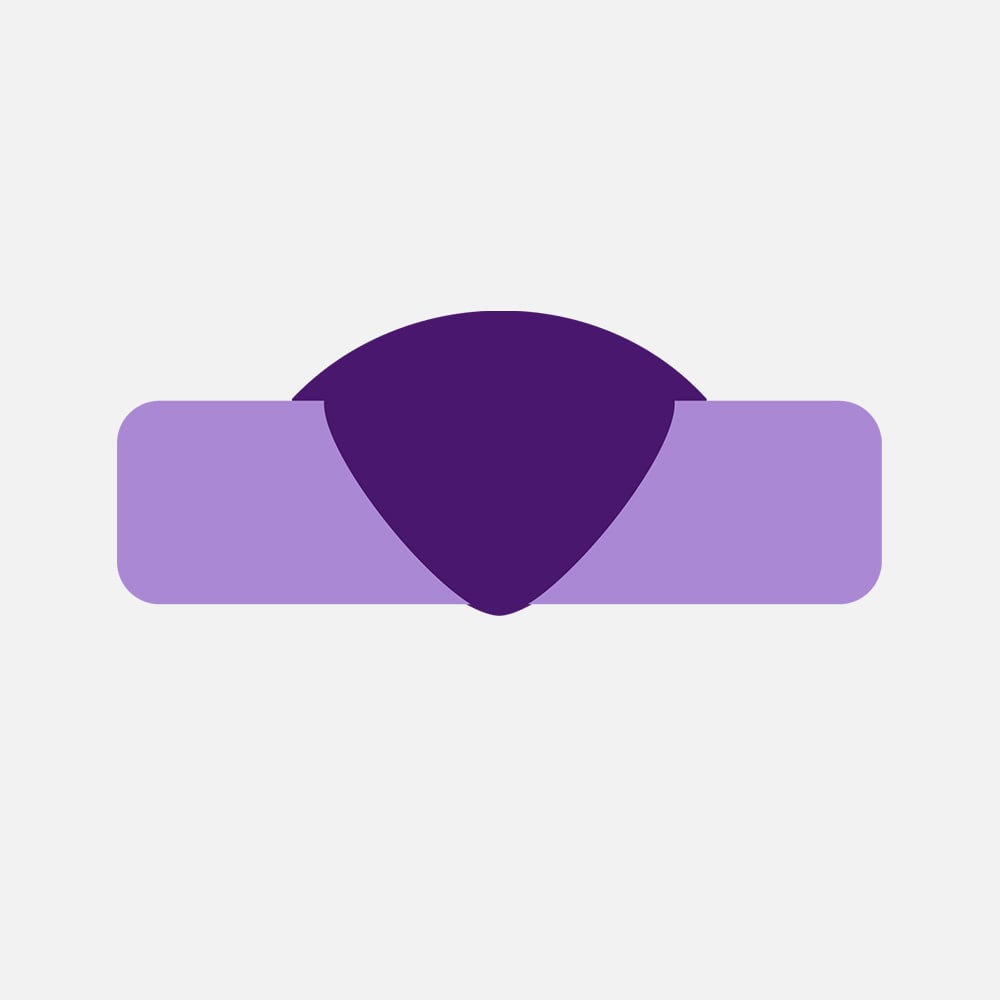

8. Excess Reinforcement

Excess reinforcement occurs when too much filler metal is deposited in the weld joint, resulting in a weld bead that is excessively convex and sits too high above the base metal. While it may seem like a stronger weld, it can actually create stress concentrations at the toes of the weld.

Although structurally less critical than cracks or lack of fusion, excess reinforcement can create stress risers along the weld surface. It may also require grinding or other post-processing to achieve a uniform surface, particularly in applications requiring strict dimensional tolerances. The sharp angle at the weld toe concentrates stress and can reduce fatigue life.

The most common causes are:

-

Slow travel speed that allows excess filler metal buildup.

-

High filler metal input where too much filler material results in a convex bead.

-

Improper heat control that leads to a bulky weld profile. In automated welding, an incorrect wire feed speed relative to the travel speed is the primary cause.

Excess Reinforcement welding defect images

Frequently Asked Questions About Reinforcement

Monitoring the bead profile during welding is the key to preventing excess reinforcement. A Xiris Weld Camera allows the operator or an automated system to see the height and shape of the weld bead as it forms. This visual feedback makes it possible to adjust the travel speed or deposition rate to maintain a consistent and appropriate bead profile.

This depends on the applicable code. AWS D1.1 limits reinforcement to 1/8 in. (3 mm) for material up to 1 in. thick. ASME Section IX and API 1104 have similar limits. Exceeding these limits requires grinding the weld flush or to the allowable height.

Not always. In some non-critical applications, a slightly convex bead is acceptable and may even be desired for added throat thickness. However, in fatigue-sensitive applications (bridges, offshore structures, pressure vessels), excess reinforcement is detrimental because the stress concentration at the weld toe reduces fatigue life.

Excess reinforcement is corrected by grinding the weld cap down to the required height, typically flush with the base metal or within the code-specified limits. Care must be taken not to grind into the base metal or create undercut during the grinding process.

9. Cracks

Cracks are the most serious type of welding defect. They are fractures that can appear in the weld metal, the heat-affected zone (HAZ), or the base metal. They can be longitudinal, transverse, or crater-shaped and can form at high temperatures (hot cracking) or after the weld has cooled (cold cracking).

Cracks represent a serious risk to structural integrity, serving as focal points for failure under cyclic or static loading. Unlike volumetric defects like porosity, cracks are planar defects that can propagate rapidly under stress, leading to catastrophic failure. In industries such as aerospace and nuclear, the presence of any crack is grounds for immediate rejection.

Cracking is caused by high levels of residual stress combined with other factors. Specific causes include:

-

Rapid cooling that induces internal stresses in the metal.

-

Material incompatibility where materials with different thermal expansion rates cause tension

-

Residual stresses from improper welding techniques. Hydrogen contamination from moisture is a major cause of cold cracking.

Cracks welding defect images

Frequently Asked Questions About Cracks

Prevention strategies depend on the type of crack. For cold cracks: use low-hydrogen consumables, preheat the material to slow the cooling rate, and ensure the joint is clean and dry. For hot cracks: choose a filler metal that is less susceptible to cracking and control the weld pool shape. Proper joint design to minimize stress and post-weld heat treatment (PWHT) for high-strength materials are also crucial.

Controlling the cooling rate is critical for preventing cracks in many high-strength steels. The Xiris XIR-1800 Thermal Camera can measure the weld’s thermal profile in real-time, including the critical t8/5 cooling time (the time to cool from 800°C to 500°C). By monitoring this parameter, operators can adjust heat input or travel speed to control the cooling rate and prevent the formation of brittle microstructures that lead to cracking.

Hydrogen-induced cracking (HIC), also known as cold cracking or delayed cracking, occurs when atomic hydrogen diffuses into the weld metal or HAZ during welding and becomes trapped as the metal cools. The hydrogen creates internal pressure that, combined with residual stress and a susceptible microstructure (martensite), causes cracks to form. This can happen hours or even days after welding.

Crater cracking occurs at the end of a weld bead when the arc is extinguished too abruptly. The crater (the depression at the end of the bead) solidifies rapidly from the outside in, creating tensile stresses that cause star-shaped cracks. It is prevented by using a crater-fill technique, where the current is gradually reduced at the end of the weld.

Cracks must be completely removed before re-welding. The crack is typically ground or gouged out, and the area is inspected (often with dye penetrant or magnetic particle testing) to confirm complete removal. The area is then re-welded using a qualified procedure, often with preheat to prevent the crack from recurring.

Preheating the base metal before welding slows the cooling rate after welding, which reduces the formation of hard, brittle microstructures (martensite) in the HAZ. It also helps hydrogen diffuse out of the weld before it can cause cracking. Preheat temperatures are specified based on the material type, thickness, and hydrogen level of the consumables.

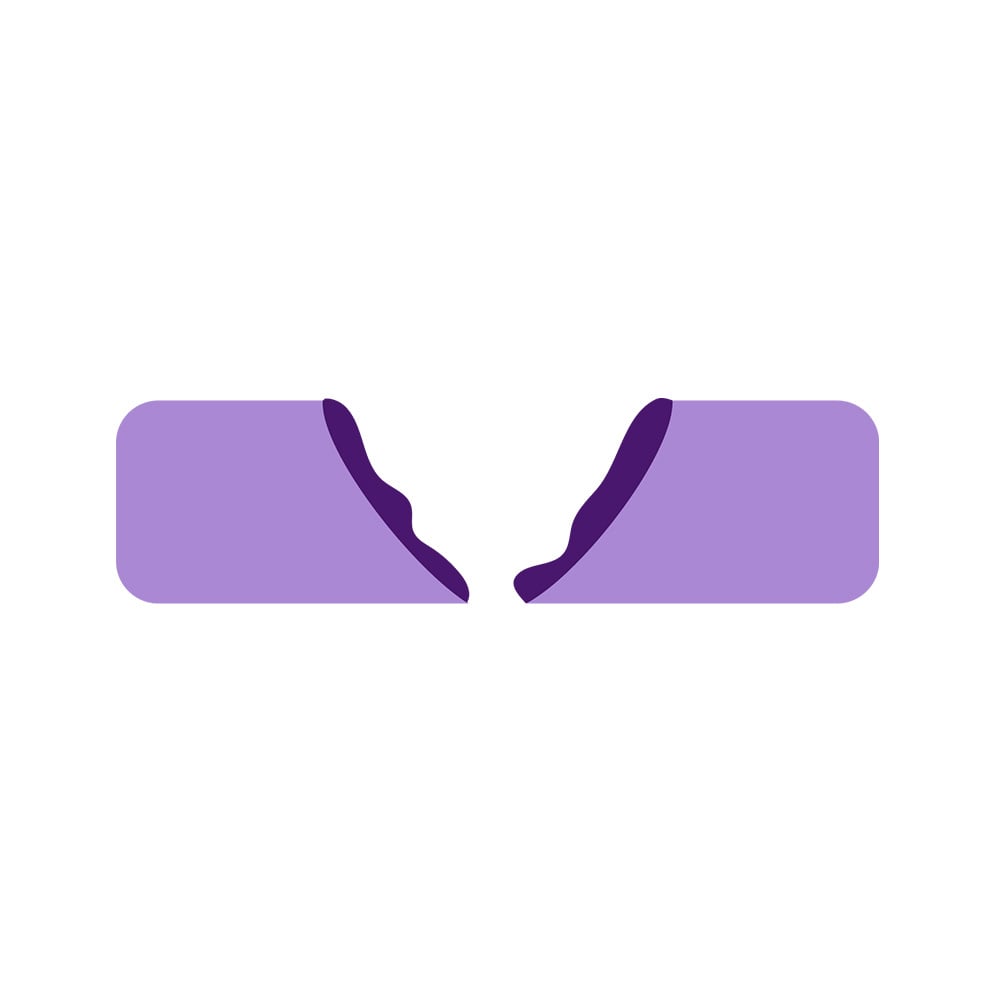

10. Burn through

Burn-through is a defect where the weld penetrates the entire thickness of the base metal, causing the molten metal to fall through and leave a hole in the joint. It is most common when welding thin materials or on open root passes.

Burn-through drastically weakens the structural integrity of the joint, especially in precision applications such as pipeline welding. Such breaches in material continuity require rework to ensure that the joint meets industry standards. In thin-wall applications, burn-through can render the part unusable.

The primary cause is excessive heat input in a localized area. Specific causes include:

-

High heat input where increased current drives too much heat through the base metal.

-

Slow travel speed that allows excessive heat concentration.

-

Poor edge preparation that enables excessive heat penetration. A root gap that is too wide also increases the risk.

Use lower heat input, especially for thinner materials, to prevent complete melting through the base. Increase travel speed to disperse heat over a larger area. Ensure uniform edge preparation for even material thickness. Using a copper backing bar can absorb excess heat and support the molten weld pool. Pulsed welding modes can also help control heat input on thin materials.

Learn more about Burn through defect

Burn through welding defect images

Video: GMAW Defect - Carbon Steel Plate - Identified Burn Through Weld

This video demonstrates GMAW on a carbon steel plate. The high heat input led to a burn-through defect, visible as localized penetration irregularities. The weld bead lacks uniformity, indicating insufficient control of process parameters critical for preventing such defects.

Video: GMAW Defect - Carbon Steel Plate - Burn Through

In this video, the excessive heat input during gas metal arc welding (GMAW) of a lap joint lead to a burn through defect and subsequent collapse of the weld pool through the bottom plate.

Frequently Asked Questions About Burn-Through

Burn-through can be detected by closely monitoring the weld pool. A Xiris Weld Camera allows an operator to see the state of the weld pool, including signs of an impending burn-through like an overly fluid or collapsing keyhole. For even greater control, the Xiris XIR-1800 Thermal Camera can monitor the temperature on the backside of the weld, providing an early warning if the heat is becoming excessive before a burn-through occurs.

Thin materials (typically less than 3 mm / 1/8 in.) are the most susceptible, regardless of the material type. However, materials with low melting points (such as aluminum) or low thermal mass are at higher risk. Sheet metal, thin-wall tubing, and root passes in pipe welding are the most common scenarios.

Repairing burn-through on thin materials is challenging. The hole must be cleaned, and a patch or backing material may be needed to support the new weld. The area is then re-welded with lower heat input. In many cases, especially in production, the part is scrapped because the repair is more costly than replacement.

Yes. Using a stitch or skip welding technique (short welds with pauses to allow cooling) can help manage heat on thin materials. Maintaining a short arc length, using a push technique, and keeping the torch moving at a consistent speed all help to prevent heat buildup in one spot.

11. Incomplete Fusion

Incomplete fusion occurs when the weld metal does not fully bond with the base metal or adjacent weld passes. It appears as an elongated gap along the weld, with sharp or rounded edges that indicate a lack of complete union. It is closely related to, and sometimes used interchangeably with, lack of fusion.

Incomplete fusion weakens the weld by creating internal planes where stress can concentrate. Under cyclic or static loading, these planes can initiate cracks, leading to premature failure of the joint. Because of its impact on structural integrity, incomplete fusion is strictly limited by fabrication standards and typically requires full rework when detected.

Causes include:

-

Improper electrode or torch angle that limits heat transfer and prevents full bonding.

-

Low heat input or excessive travel speed that reduces penetration into the joint surfaces.

-

Contaminated base metal where oxides, oils, or dirt block proper fusion.

Maintain correct electrode or torch angle to ensure heat is directed to the bonding surfaces. Adjust current and travel speed to provide adequate heat input for complete fusion. Clean the base metal thoroughly to remove all oxides, oil, and other contaminants. In multi-pass welding, ensure each pass adequately remelts the surface of the previous pass.

Incomplete fusion defect images

Frequently Asked Questions About Fusion

Visual monitoring is key. A Xiris Weld Camera provides a detailed view of the weld pool’s interaction with the joint. Operators can watch to ensure the molten metal is wetting the sidewalls and achieving a good tie-in, which are direct indicators of good fusion. This real-time feedback is invaluable for preventing this defect.

Incomplete fusion is best detected using ultrasonic testing (UT), which can identify the planar discontinuity as a strong reflected signal. Radiographic testing (RT) can also detect it, but it may be harder to see on film if the defect is oriented parallel to the X-ray beam. Phased array UT is particularly effective for this defect.

In practice, the terms are often used interchangeably. However, some codes distinguish between them: "lack of fusion" may refer specifically to the failure to fuse with the sidewall or a previous pass, while "incomplete fusion" may be a broader term that also includes the root. The key point is that both describe a failure to achieve a complete metallurgical bond.

Maintaining the correct inter-pass temperature is important for preventing incomplete fusion in multi-pass welds. If the previous pass cools too much before the next one is applied, the new weld metal may not have enough energy to remelt the surface and achieve fusion. Conversely, if the inter-pass temperature is too high, other problems like hot cracking can occur.

12. Slag inclusion

Slag inclusion is a defect where nonmetallic slag particles remain trapped inside the weld metal or between passes. It appears as elongated lines or isolated pockets within the weld, often parallel to the weld axis, and can sometimes extend through the joint thickness.

Slag inclusions create discontinuities that concentrate stress and weaken the joint. They can also trigger localized corrosion in crevices where moisture collects. In critical structures, they reduce fatigue resistance and often require grinding and re‑welding to restore strength and meet inspection codes.

The primary causes are:

-

Poor inter-pass cleaning, where residual slag from previous weld passes remains trapped in the joint.

-

Improper electrode manipulation or bead profile that creates voids or pockets where slag can accumulate.

-

Incorrect travel speed or current settings that lead to uneven fusion and make slag removal difficult.

Clean and remove all slag between weld passes using chipping, wire brushing, or grinding. Maintain steady travel speed and proper current to ensure smooth bead formation and adequate fusion. Manipulate the electrode correctly to avoid pockets or undercuts that can trap slag. Proper joint design that allows good access for cleaning is also important.

Slag inclusion defect images

Frequently Asked Questions About Slag Inclusion

While internal slag requires NDT (typically radiography), operators can often see slag getting trapped at the edges of the weld pool during the process. A Xiris Weld Camera provides the clarity needed to see the interaction between the molten slag and the weld pool, helping operators adjust their technique to prevent the slag from becoming entrapped. For more details, see our article on What Is Slag Inclusion in Welding? and How to Prevent it.

Slag is produced by flux-based welding processes: Shielded Metal Arc Welding (SMAW/Stick), Flux-Cored Arc Welding (FCAW), Submerged Arc Welding (SAW), and Electroslag Welding (ESW). Gas-shielded processes like GMAW (solid wire) and GTAW do not produce slag, making them inherently free of this defect.

Radiographic testing (RT) is the most common method for detecting slag inclusions. On a radiograph, slag appears as dark, irregularly shaped indications within the weld. Ultrasonic testing can also detect slag, though it may be harder to characterize than planar defects.

The area containing the slag must be ground or gouged out until clean weld metal is exposed. The cavity is then re-welded, ensuring proper inter-pass cleaning to prevent recurrence. The repaired area should be re-inspected to confirm the slag has been fully removed.

“Wagon tracks” is a colloquial term for linear slag inclusions that run along both sides of the weld root, resembling the tracks left by a wagon. They are caused by slag being trapped at the toes of the root pass and are a specific, common form of slag inclusion in multi-pass welds.

13. Arc Strikes

An arc strike is a discontinuity resulting from an arc, consisting of any localized remelted metal, heat-affected metal, or change in the surface profile of any part of a weld or base metal outside the intended weld path. Essentially, it is damage caused by accidentally striking the arc outside the joint.

Arc strikes can create small heat-affected zones that may harden and become brittle, especially in high-strength steels. These localized zones can act as stress concentrators, increasing the risk of crack initiation and propagation. In structural or pressure applications, arc strikes are considered unacceptable and often require grinding and inspection.

Arc strikes are almost always a result of poor technique or carelessness:

-

Accidental electrode contact that creates localized melting and surface marks.

-

Poor tool or cable control that allows unintended touching of the base metal.

-

Sticking and breaking electrodes that leave small scars or depressions when detached.

Arc strikes defect images

Frequently Asked Questions About Arc Strikes

Each arc strike creates a small area that has been rapidly heated and then quenched. This can create localized hard, brittle spots (martensite) on the surface of the metal, which can act as initiation points for cracks, especially under fatigue loading. They are considered a serious defect in critical applications such as pressure vessels and structural steel.

Arc strikes are repaired by grinding the affected area smooth and then inspecting it (typically with magnetic particle or dye penetrant testing) to ensure no micro-cracks have formed. If cracks are found, the area must be ground deeper until all cracks are removed, and then re-inspected.

In critical applications (pressure vessels, structural steel under cyclic loading, aerospace), arc strikes are always rejectable and must be repaired. In less critical applications, some codes may allow minor arc strikes if they are ground smooth and inspected. The applicable code and the service conditions of the structure determine the acceptance criteria.

Yes. The rapid heating and cooling cycle of an arc strike can create a hard, hydrogen-susceptible microstructure in the base metal. If hydrogen is present (from moisture in the air or on the surface), the arc strike can serve as an initiation point for hydrogen-induced cracking, particularly in high-strength or high-carbon steels.

14. Distortion

Weld distortion is the warping, bending, or twisting of a workpiece caused by the non-uniform heating and cooling of the weld joint. As the weld metal heats and expands, and then cools and contracts, it exerts powerful forces on the surrounding base metal, causing it to change shape.

Distortion can compromise dimensional accuracy, alignment, and structural reliability of welded assemblies. If uncorrected, it may lead to fit-up problems, additional rework, or reduced service life of the welded component. In precision manufacturing, even small amounts of distortion can render a part unusable.

There are several types:

-

Transverse shrinkage, where the plates pull together perpendicular to the weld.

-

Longitudinal shrinkage, where the weld contracts along its length.

-

Angular distortion, where the plates rotate around the weld axis

-

Bowing or camber, a longitudinal bending of the entire assembly.

-

Twisting, a rotational deformation. Two or more types can occur simultaneously.

Distortion is caused by:

-

Uneven heating and cooling that generates nonuniform expansion and shrinkage across the joint.

-

Excess weld metal deposition that increases shrinkage forces.

-

Poor joint design or unbalanced welding sequence that fails to distribute stresses evenly. The more heat input, the more distortion.

Weld distortion defect images

Frequently Asked Questions About Weld Distortion

Strategies focus on minimizing and managing heat: limit weld size and avoid depositing more metal than necessary. Use intermittent welding instead of continuous beads where design allows. Use fixtures, clamps, or preset assemblies to control and resist distortion forces. A balanced welding sequence (alternating sides) helps distribute stresses evenly. The backstep technique and staggered welding sequences are also effective.

By controlling heat input, you can control distortion. The Xiris XIR-1800 Thermal Camera allows for precise monitoring of the thermal field around the weld. This enables the development of welding procedures that use minimal heat input while still achieving the required penetration, and it can verify that inter-pass temperatures are controlled, which is a key factor in managing distortion in multi-pass welds.

Yes, but it is costly and time-consuming. Methods include mechanical straightening (using presses or jacks), flame straightening (applying localized heat to induce controlled shrinkage), and stress-relieving heat treatments. Prevention is always more economical than correction.

Yes. Thinner materials are more susceptible to distortion because they have less stiffness to resist the shrinkage forces. However, thick materials can also distort significantly if the weld volume (and therefore the shrinkage force) is large, such as in heavy multi-pass welds.

Presetting involves positioning the parts before welding so that the expected distortion will pull them into the correct final alignment. For example, if angular distortion is expected to close a joint by 5°, the parts are set 5° open before welding. This requires experience and knowledge of the expected distortion for a given joint and procedure.

The order in which welds are made has a significant impact on distortion. A balanced sequence (e.g., alternating between opposite sides of a structure) helps to equalize shrinkage forces. Welding from the center outward, or using a backstep technique, can also reduce overall distortion compared to welding in a single continuous pass from one end to the other.

15. Cold lap

Cold lap is a defect that is very similar to overlap. It occurs when the molten filler metal flows over the surface of the base metal or a previous weld bead without properly fusing to it. It is caused by a lack of sufficient heat to achieve fusion, resulting in a discontinuity at the toe of the weld.

Cold lap creates weak points along the weld toes where cracks can initiate under stress. Because the metal has not fused properly, the joint’s load-bearing capacity is reduced, and the defect can lead to premature failure if subjected to cyclic or dynamic loads.

The primary causes are:

-

Low heat input that prevents the molten metal from bonding to the base metal.

-

Improper travel speed, where moving too slowly piles up metal without full fusion.

-

Incorrect electrode angle or technique that directs the molten pool away from the joint surfaces. It is particularly common in short-circuit MIG welding.

Increase heat input to achieve proper fusion between filler and base metal. Maintain an even travel speed to allow the weld pool to wet and bond correctly. Hold the electrode or torch at the correct angle to ensure fusion along the weld toes. A slight weaving motion can also help to preheat the area just ahead of the weld pool and promote better fusion.

Cold lap defect images

Frequently Asked Questions About Cold Lap

Like overlap, cold lap is a surface defect that can be detected visually. A Xiris Weld Camera gives the operator a clear, close-up view of the weld pool and the leading edge of the bead. The operator can see if the molten metal is flowing smoothly and fusing with the base metal, or if it is sluggish and simply rolling over the surface, allowing for immediate correction.

The terms are closely related and often used interchangeably. “Cold lap” emphasizes the thermal cause of the defect (insufficient heat for fusion), while “overlap” is the more formal term used in welding codes and standards. Both describe weld metal that has flowed over the base metal without achieving a metallurgical bond.

Yes. Cold lap is particularly common in short-circuit GMAW (MIG) welding, where the heat input is inherently lower than in spray or pulsed transfer modes. It can also occur in SMAW (stick) welding with low-hydrogen electrodes if the amperage is set too low for the electrode diameter.

The unfused metal must be removed by grinding. If the remaining weld is insufficient, the area is re-welded with higher heat input and correct technique to ensure proper fusion at the toes. Simply grinding the surface smooth is not a valid repair if the underlying metal is not fused.

Weld Defect Detection with Xiris Automation Technology

Xiris’s welding cameras deliver real-time, high-resolution imaging that overcomes the limits of traditional inspection methods. Designed for continuous monitoring, they enable immediate defect detection and adjustments during welding, ensuring higher quality and improved productivity. Here's how:

- Real-Time, High-Definition Imaging: Unlike post-process inspections, Xiris cameras let operators monitor the weld pool, arc, and surrounding area live, catching issues like porosity or cracks instantly and adjusting on the spot.

- Detection of Subtle Inconsistencies: Advanced optics detect minor weld variations, such as penetration or alignment issues, crucial for precision applications to ensure high-quality results.

- Automated Data Collection for Improvement: Xiris systems record footage and data, enabling manufacturers to analyze trends, refine processes, and maintain compliance with traceable quality records.

- Non-Destructive, Continuous Monitoring: Xiris technology avoids production interruptions, offering real-time monitoring to reduce downtime and ensure consistent weld quality.

- Integrating Xiris cameras streamlines quality management, minimizes defects, and boosts productivity on the production floor.