Machine Vision technology involves the automatic acquisition and processing of an image to obtain desired information for controlling an activity. This control is achieved by determining if an object in the image meets specific acceptance criteria and notifying the process of the results.

The process begins with the acquisition of an image by any type of device that can produce an electronic signal, such as a video camera, line scanner, etc. Once an image is acquired, it is stored electronically and, if necessary, sent to a computer for processing.

The original image is enhanced to make the required features more visible and then automatically compared with a model of the expected results to infer the object's true nature. An acceptance decision is made based on this comparison and a signal is produced to alert the production process of the inspection results.

Inspecting simple objects in simple scenes over a large number of cycles is best suited to Machine Vision, whereas inspecting objects in a complex scene over a low number of cycles is best suited to human vision.

Automatic Inspection

Most often, Machine Vision technology is used to acquire an image of a process or object to send a signal back to a machine, which provides the quality or process control. This is known as Automatic Inspection, and it offers numerous benefits to manufacturers:

- Improved quality. By using an Automatic Inspection system, the inspection of manufactured goods becomes less subjective and more scientific.

- Reduced labor costs. Many repetitive inspection tasks that are labor-intensive can be replaced with Automatic Inspection systems that operate 24 hours per day, 365 days per year.

- Reduced component wastage. By using Automatic Inspection systems to increase the detection rate of defects earlier in a manufacturing process, manufacturers avoid adding value to work-in-process before errors are detected.

- Improved defect detection rate or errors. Manual inspection is at best 70-80% effective at detecting defects in a repetitive inspection process. Using Automatic Inspection systems, manufacturers can obtain a defect detection rate that is almost 100% of defects.

Images for Human Inspection

Machine Vision technology is also sometimes used to acquire an image and enhance it to make features more visible for a human to make a decision.

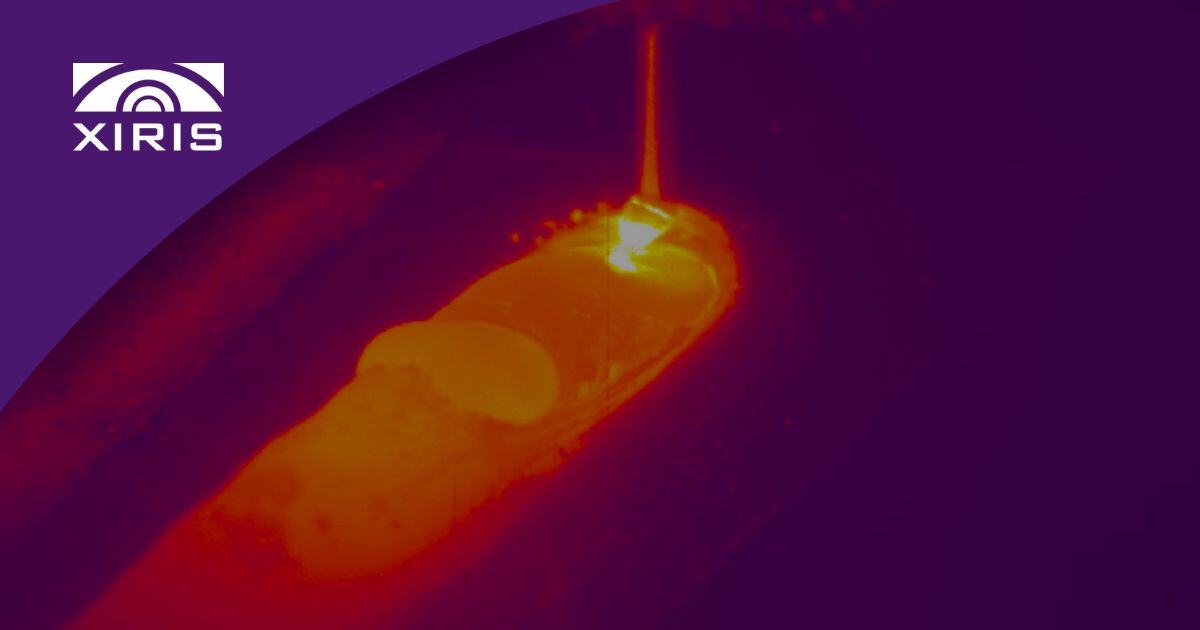

Xiris has implemented numerous Machine Vision technologies into all of its products. Our XVC-O Weld Camera incorporates some key optical, electronics, and software technologies that improve the quality of the final image of a weld process to help operators make better decisions when monitoring welding.

Conclusion

Whether used in Automatic Inspections or to provide operators with better images for their decision-making, Machine Vision provides greater control over the manufacturing inspection process—leading to reduced costs and improved quality.