When making a business case for a technologically advanced Weld Camera such as the Xiris XVC-O, don’t limit your focus to direct costs and benefits only. In this final installment of our series on How to Justify the Cost of a Weld Camera, we take a look at other substantial cost savings and benefits that can be achieved by investing in the latest Weld Camera technology.

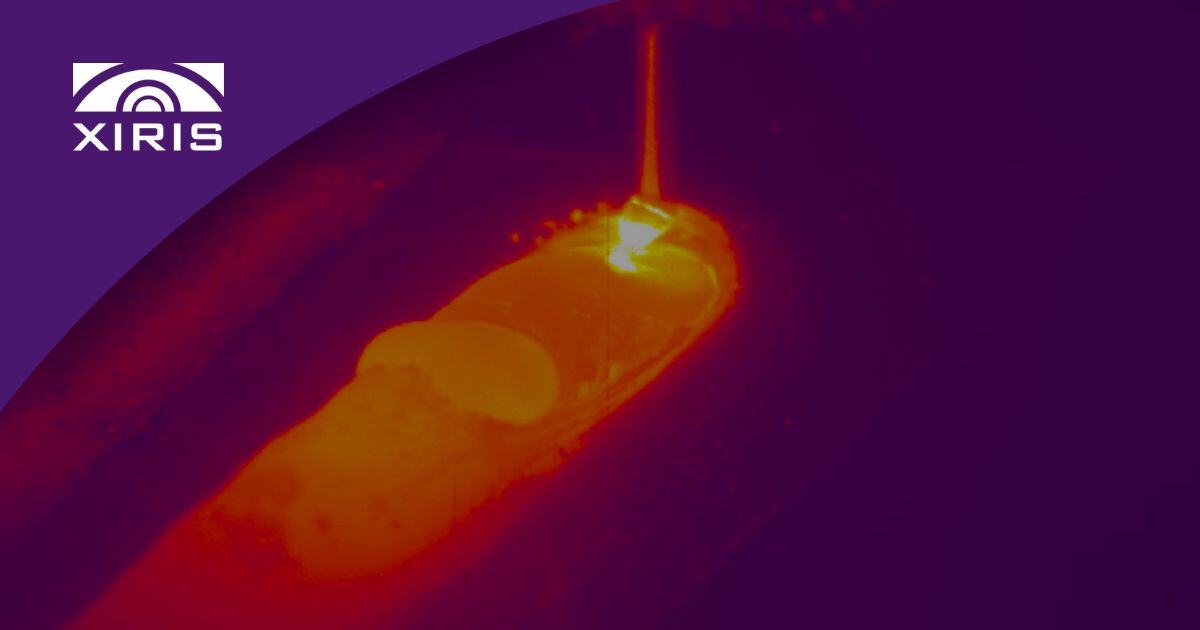

Weld Cameras can have a positive financial impact for a fabricator in many indirect ways—but only with High Dynamic Range imaging capability, which enables the camera to simultaneously capture the detail of the super-bright welding arc and the dark surrounding background.

A Weld Camera with this technology allows fabricators to implement remote monitoring systems that not only provide the best-possible weld visibility, but also improve profitability away from the welding cell in numerous ways, including:

- Elimination of the need to buy other more expensive Laser Seam Tracking equipment, because in some cases a Weld Camera allows an operator to perform the task better than an automatic Laser Seam Tracker would.

- Increased effectiveness of other capital investments (e.g., improved productivity and quality control from automated welding equipment).

- Reduction of shipping, price discounts, and other costs related to returned products due to deficient welds.

- Better attraction and retention of skilled workers, who are more willing to work in a remote monitoring environment than in the more dangerous and hazardous conditions proximate to the weld area.

- Lower safety and health costs (e.g., workers compensation insurance, group medical coverage, lost work time, hiring and training of replacements, possible litigation) due to the safer and healthier environment of monitoring the weld process remotely.

- More-effective employee training made possible by using the video records of ideal weld processes generated by the Weld Camera and its image-processing software.

- Enhanced marketing and sales efforts due to improved quality assurance that becomes a key differentiator for the progressive fabricator.

- Improved quality assurance and continuous improvement of processes through offline audit/review of the recorded video.

- Reduced risk of producing large quantities of suspect material, as well as enhanced ability to meet customer needs, due to improved visibility of the weld area detail.

- Reduction or elimination of recurring quality defects such as weld porosity or contamination that are otherwise difficult to detect on an ongoing basis.

- Process fine-tuning and minimization of scrap because of the instant feedback of the weld head performance provided to the operator.

- Detection of discontinuities that other inspection equipment (eddy current, ultrasonic) cannot detect.

Conclusion

The indirect cost savings and benefits of Weld Cameras can be quantified to a degree, but it’s harder than with direct costs and benefits. However, it’s important to keep in mind that a business case can include relatively qualitative justifications, as long as they’re well-reasoned and backed with as much evidence as possible. The indirect impact of Weld Cameras is certainly a large part of the overall financial story.