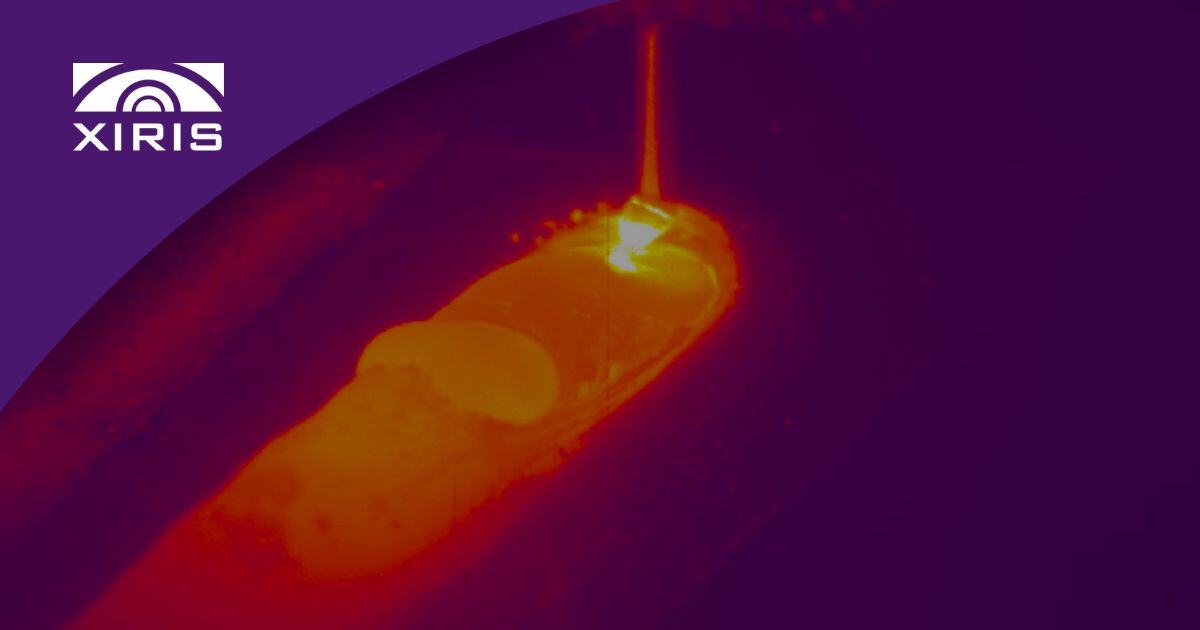

In order to properly image an open arc weld and its background, a Weld Camera with High Dynamic Range imaging capability is required to properly capture the extreme variation in brightness that could occur at the weld head—a variation that often exceeds 10,000,000:1.

To achieve a High Dynamic Range image, the incoming video signal needs to be modified to suppress the portion of the signal where there is not much content, leaving the portion where there is lots of content. Because there are fewer details per level of increased brightness, the much-brighter arc-weld portion of the image can be compressed more than its darker background areas.

The background areas, however, have much valuable content for the viewer and should not be compressed at all.

With a Weld Camera with High Dynamic Range imaging—such as the Xiris XVC-O —operators can avoid the need to implement any auxiliary aperture to regulate the amount of light striking the camera. This means they only have to set up the camera once and will have to make fewer in-process adjustments than for Weld Cameras without High Dynamic Range imaging.

How It Works

In the XVC-O Weld Camera, a logarithmic function is used to compress the brightest portion of the image while leaving the darkest portion virtually uncompressed, as shown below:

.jpg?width=450&height=353&name=diagram-no_aperture_required_blog_(640x503).jpg)

Camera System Output and Weld Arc Light Input

Even though the XVC-O Weld Camera can acquire images at 140+ dB dynamic range by using a special CMOS sensor and electronics, it’s quite a challenge to convert this high range of brightness into a meaningful image on a standard digital monitor, which displays video in 8-bit resolution, or 256 grey levels. To overcome this challenge, the XVC-O uses some additional electronics to obtain the type of logarithmic response curve needed to properly display welding images —suppressing the response in the area of the arc intensity and leaving it as a near-linear response in the darker region of the range, where background detail would normally appear.

The result is an excellent representation of the weld arc and its background on a standard 256-grey-level digital monitor.

Conclusion

High Dynamic Range cameras such as the XVC-O Weld Camera use a logarithmic sensor and processing electronics to achieve a dynamic range that exceeds 140 dB. This ability to see both the super-bright open arc and the dark background frees operators from having to use an auxiliary aperture to control the amount of light hitting the camera, while providing them with better visibility into the weld process than possible with direct monitoring.