As imaging technology continues to evolve, a growing number of end users want Weld Cameras with the latest imaging technology integrated into their automated welding cells.

Indeed, for some end users who aren’t even automated yet, the desire to take advantage of a Weld Camera may be a primary motivation for finally moving to automation. However, most of the demand for integrated Weld Cameras is coming from end users who are already automated but want the additional advantages Weld Cameras bring.

Indeed, for some end users who aren’t even automated yet, the desire to take advantage of a Weld Camera may be a primary motivation for finally moving to automation. However, most of the demand for integrated Weld Cameras is coming from end users who are already automated but want the additional advantages Weld Cameras bring.

In this market environment, machine builders and systems integrators building automated welding cells and equipment can put themselves a step ahead of the competition by integrating Weld Cameras into their product lines.

Weld Cameras Have Multiple Benefits for End Users

Weld Cameras allow end users to remotely monitor their welding process, and then make in-process adjustments that reduce production costs and improve quality. Weld Cameras can also create a video record of the weld processes they image, which can be used for off-line troubleshooting, identifying process-improvement opportunities, performing quality audits, and training operators.

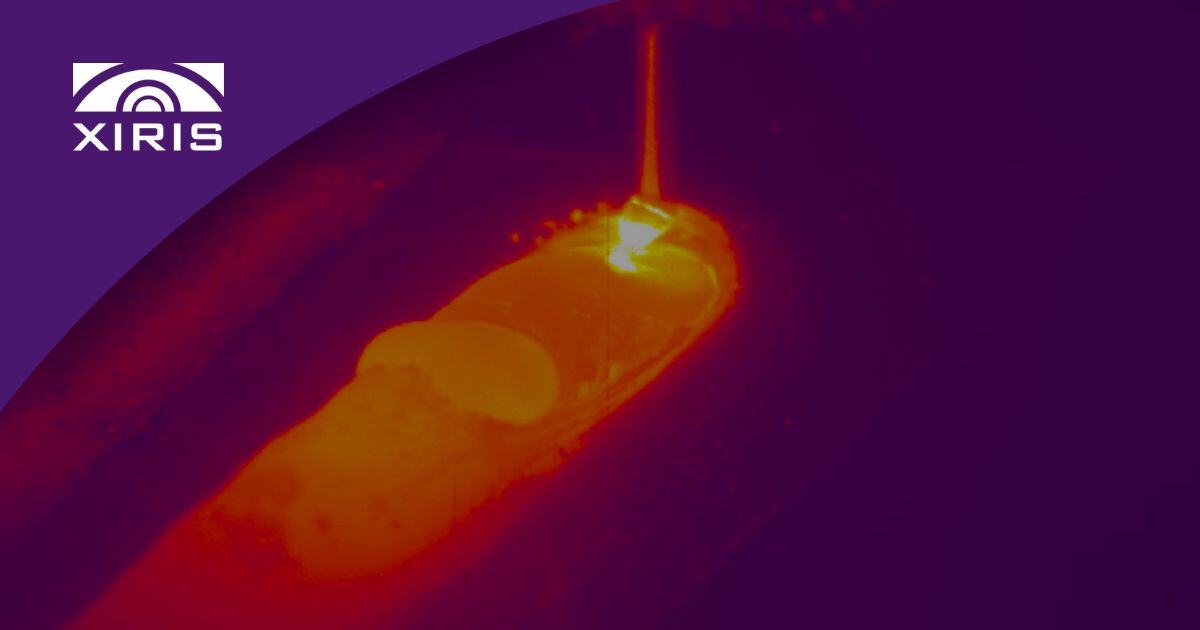

And with the latest advances in electronics technology providing High Dynamic Range imaging—which allows for clear detail of both the super-bright open weld arc and its darker background in a weld scene—Weld Cameras can now provide better visibility of the weld process than previously possible.

Weld Cameras Can Be a Differentiator

Weld Camera technology has matured to the point that it’s generally the most cost-effective and efficient remote weld monitoring solution available for end users. But it’s still underused in automated welding processes—presenting an ideal opportunity for “early adopter” OEMs and systems integrators to differentiate themselves from the competition.

Inclusion of this technology in an OEM’s line of welding solutions can set the company apart from the crowd, marking it as an innovator in the minds of its prospective customers.

Weld Cameras Result in a Better Automated Solution

When an OEM makes product changes that result in increased profitability for its end user customers, the OEM builds loyalty and improves its corporate brand. By integrating a Weld Camera into its automated welding equipment, an OEM can improve ease of use, functionality, and overall system performance of its equipment, leading eventually to a more profitable system deployment.

When a Weld Camera is integrated into a piece of automated welding equipment, the marginal increase in the cost of the equipment will be dwarfed by the productivity and quality-control benefits that end user customers will receive. Not all automated welding equipment is suitable for the introduction of Weld Cameras, but for equipment that is, Weld Cameras can dramatically transform the process for the equipment operator.

Conclusion

With the advent of High Dynamic Range imaging technology, Weld Cameras will almost certainly see significant growth in their use throughout the welding industry. This creates an opportunity for machine builders and systems integrators of automated welding cells to offer Weld Cameras integrated into their equipment to achieve a significant competitive advantage.

Image courtesy of Steven Depolo, Creative Commons.