An increasing number of tube and pipe fabricators are turning from conventional plasma and GTAW (TIG) welding to laser beam welding (LBW), which can provide higher welding rates, stronger welds, and deeper, narrower keyholes.

But there’s a tradeoff to the advantages of LBW systems—the resulting need to improve monitoring of the edge presentation and seam location.

Just as with GTAW and plasma welding, the strip edge presentation and seam location relative to the weld head must be controlled to minimize defects such as mismatch, edge wave, edge gap, and seam wandering. But because a laser beam spot is about 10 percent the size of a GTAW or plasma arc, achieving this control is much more difficult in LBW.

The Advantages of Laser Beam Welding

There are clear and compelling reasons for the increased popularity of LBW among tube and pipe fabricators.

Speed

LBW results in increased productivity for the fabricator because it can be 50 percent or more faster than conventional welding techniques, if the laser is appropriately sized and fiber lasers are used.

Power density

LBW systems have greater power density than GTAW or plasma welding systems. The heat in a laser system concentrates into such a small spot that it forms a keyhole weld, which generally extends through the entire thickness of the material and has a narrow heat-affected zone.

The capability for a deeper, narrower weld is valuable in many applications, and the narrow heat-affected zone results in a stronger weld because less of the parent material is distorted or changed in the weld heat zone.

The Challenges – How to Achieve Greater Precision

While the narrower heat-affected zone of LBW creates stronger welds, the small spot size makes it difficult to keep the laser on the seam as the seam wanders from left to right, requiring very precise monitoring to keep the seam on track.

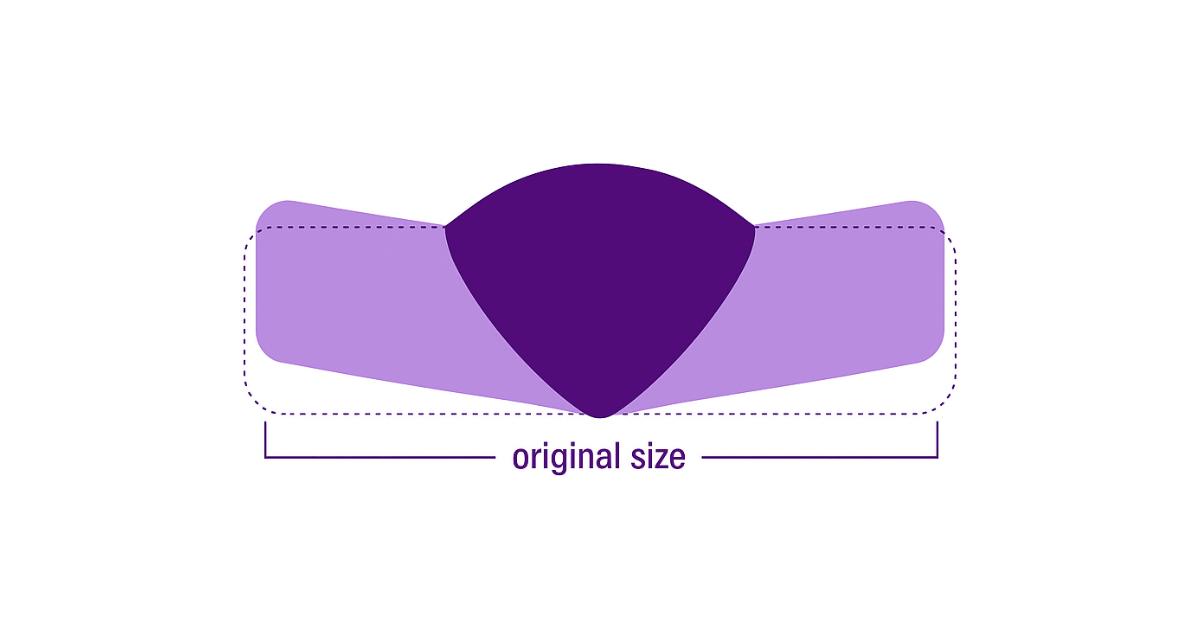

Laser-based Weld Inspection Systems, such as the Xiris WI2000p, have proven to be an effective way to monitor if the seam is out of alignment. Using a triangulated laser and camera solution to monitor the weld seam, the typical laser-based Weld Inspection System can accurately track the seam over an area of 25 mm (1”)—enough to compensate for seam wandering in properly maintained mills.

And once the Weld Inspection System has been taught the correct weld parameters, it monitors the process and alerts operators when parameters are exceeded.

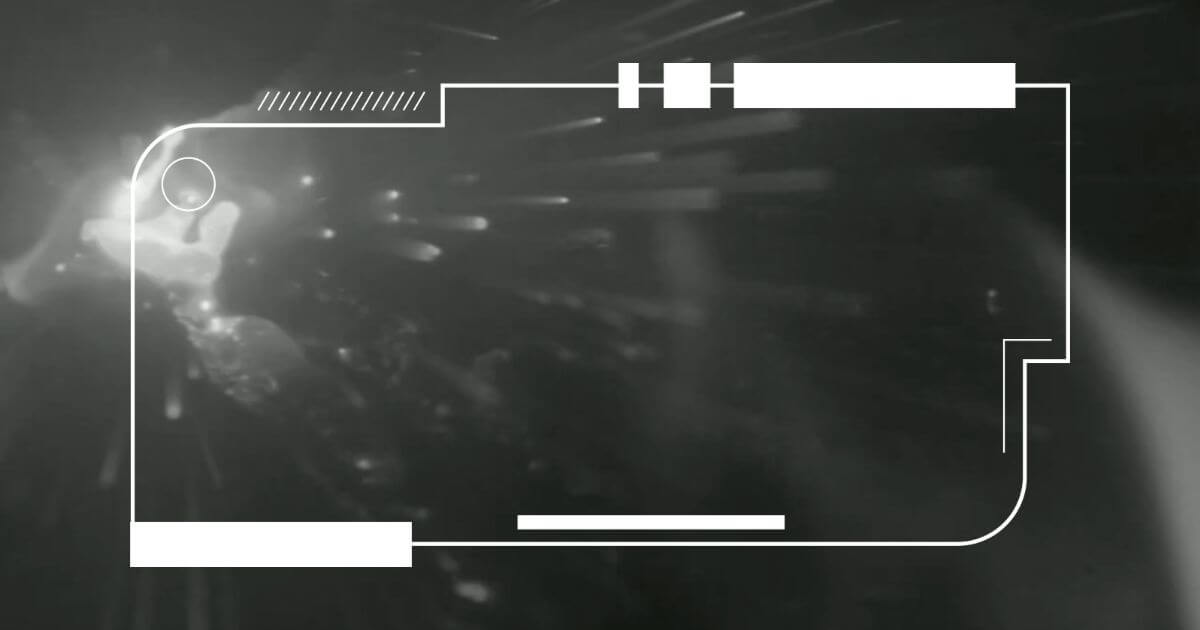

Weld Cameras are another tool that progressive tube and pipe fabricators are using to enhance their monitoring of LBW. A Weld Camera with High Dynamic Range imaging—such as the Xiris XVC-O—can allow operators to watch the laser beam process in real time, with clear visibility of the entire brightness range of the weld scene. This visibility allows operators to use their judgment and experience to make adjustments that improve quality and productivity during production.

Laser Cladding Image From XVC-O

Conclusion

The advent of laser-based welding processes in tube and pipe production brings a number of advantages to the fabricator. However, with those advantages, there is a need for enhanced monitoring because the laser weld is so small.

Laser-based Weld Inspection Systems provide a useful way to monitor the weld quality after the fact and Weld Cameras with High Dynamic Range imaging allow an operator to see all the details of the weld and its background during the process to provide instant quality and process control.