Research and Development is a crucial element of success in Metal Additive Manufacturing. However, R&D has traditionally been expensive and highly time-consuming.

A primary cause of this cost and time is that Metal AM machine operators cannot make adjustments to a first-run part in real time. Engineers must wait for the build of the entire part before they can test and analyze it. This process results in excess time—stopping the machine to make adjustments, testing and analyzing after the first run, and future runs after post-run adjustments are made. Each additional run also drives up materials’ costs and involves costly, time-consuming stoppages for reprogramming new runs.

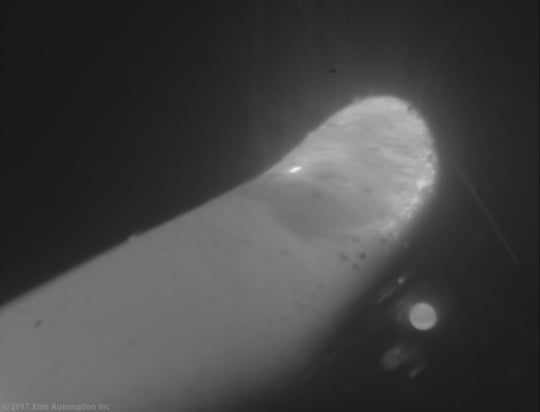

The powder feed/ droplet formation in Metal Additive Manufacturing as seen with Xiris Weld Camera

Fortunately, this cost/time problem can be minimized. You no longer need to wait to test and analyze first-run Metal AM parts until they are completed. Recent developments in software and camera technology are allowing operators to use High Dynamic Range (HDR) weld cameras to make adjustments to a part in real time during the initial run. Process engineers can also monitor the sequence and program in real-time adjustments.

By integrating HDR weld cameras into the Metal AM machine, operators in any setup can get clear, high-contrast views of the torch and wire (or powder flow) and their alignment to the process and other material settings. Operators can monitor material inputs and achieve ideal conditions on a consistent basis throughout the process, without stopping the machine.

Xiris’s HDR weld cameras feature the latest software and camera technology. Using our cameras, operators can monitor the weld torch, its immediate background, and material deposits from previous machine passes—with a level of visibility that has never been possible before. Importantly, this visibility is even greater than when operators are situated close enough to the Metal AM process to see it with their own eyes. Our HDR weld cameras not only allow operators to see more detail, they eliminate the danger and labor time involved with manual monitoring.

Often, due to thermal stresses, a deposited layer of material can start to warp. To compensate, operators can use the clear images from the HDR weld cameras to make precise adjustments to align the torch, wire and/or powder to the warped material, optimizing material alignment and overlap during challenging Metal AM layer deposition.

After an initial run, process engineers can use the recorded video from the HDR weld camera, in conjunction with data from other quality systems, to review the material deposition and resolve issues more quickly than waiting for traditional testing and analysis to take place when the part has been completed. For example, if a layer is deposited with significant porosity, it may only be detected if the operator is using HDR cameras to monitor the melt process. Without such tools, porosity in the material could only be detected by a form of destructive testing after the part has been completed.

Summary

Metal AM machine operators can use HDR weld cameras to monitor the initial build of a Metal AM part, providing them with immediate feedback, rather than waiting for the build of an entire part before inspecting, testing, and analyzing it. The result is decreased build times, less engineering/operator cost, and lower materials’ costs. These benefits make the latest in HDR weld cameras a valuable, cost-effective tool in any R&D process for Metal AM.

.png)

.png)