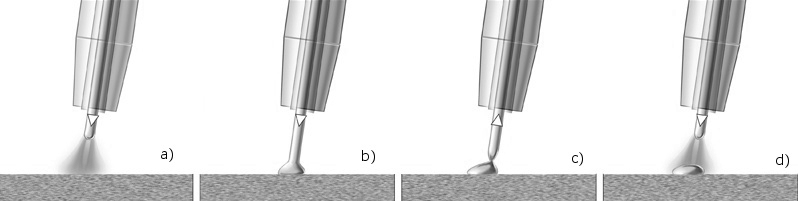

Cold Metal Transfer (CMT) welding is a variant of the GMAW process developed by Fronius. It uses a method similar to a short-circuiting transfer process,1 where the wire moves forward but instantly retracts back as soon as the short circuit occurs, which detaches the droplet and reduces heat input during the arc-burning phase.

The process can be divided into three separate phases. Each phase differing in the level of current and arc voltage, creating a variation in the level of brightness of the weld arc. When an expulsion occurs and an arc is established, the image may be very bright as the arc intensifies to its maximum. However, when the arc is extinguished as the wire makes contact with the parent material, the image can become quite dark. This can make it difficult to capture a clear image of the weld due to the variation in light.

CMT (cold metal transfer) process (Courtesy of Low Heat Joining) 2

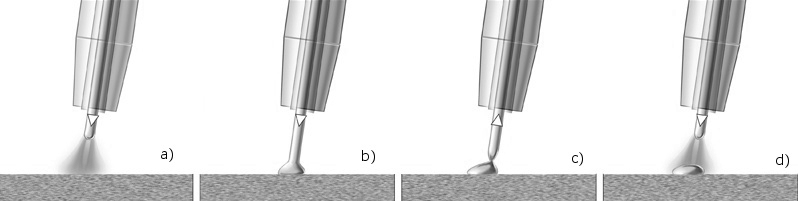

To solve this, a Xiris weld camera can be triggered by an electrical pulse generated by the CMT welding power supply. By triggering the camera acquisition at the same point in the CMT weld cycle, a more consistent video of the weld process can be acquired, as the light levels will be more consistent. To do this, an external trigger signal is created based on the electrical current level generated by the welding power supply. When the current hits a threshold, a trigger signal is generated and sent to the camera to initiate image acquisition. The result is acquired video with consistent brightness and image quality across each frame.

What the CMT weld process looks like on a Xiris Camera

What the CMT weld process looks like on a Xiris Camera

Imaging a CMT welding process can become difficult if using a weld camera in free running mode, however using a Xiris Weld Camera, a trigger signal can be generated from the power supply to acquire consistent images at similar points in the CMT process. The result is a uniform video with more consistent lighting from frame to frame, that provides greater opportunity for image analysis of the welding process.

What the CMT weld process looks like on a Xiris Camera

What the CMT weld process looks like on a Xiris Camera

.png)

.png)