MQTT, or Message Queuing Telemetry Transport, is an industry standard communication protocol rapidly appearing in the welding industry where many of the major welding power supply companies are building equipment that is MQTT compatible.

MQTT is an open OASIS, and ISO, standard lightweight, publish-subscribe network protocol that transports messages between devices. It is becoming popular for IoT (Internet of Things) equipment. The protocol usually runs over TCP/IP; however, any network protocol that provides ordered, lossless, bi-directional connections can support MQTT.

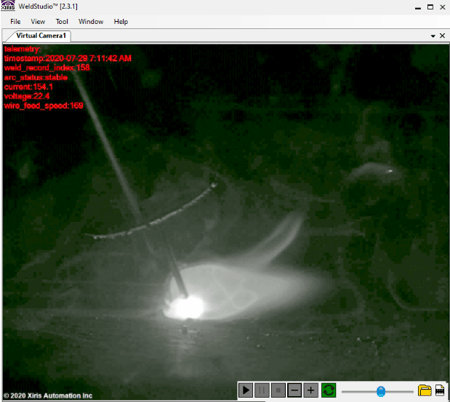

Xiris has developed an MQTT interface so that the Xiris weld cameras are able to securely receive welding data from suitable welding machine, such as a Lincoln Power Wave® power source. This allows welding data to be synchronized with the weld camera video data for on-screen display and recorded for off-line review.

Welding Data Telemetry Embedded with Image Display and Recording

By providing the ability to monitor both the welding parameters and images at the same time, welders are able to better monitor all aspects of their welding process without needing to look away at other screens. The data can be annotated directly into the video image so that on playback, images can be reviewed off line showing the exact welding data generated at the time of the video.

Applications suitable to this technology include:

- Remote welding applications where the welder does not have easy access to the welding machines to verify setup and parameters.

- Critical welding applications where the process inputs (Weld ID and parameters) need to be monitored for quality assurance or as a reference for troubleshooting.

- Welder training that can show the welder what the resulting weld looked like based on the settings of the welding supply, and remote or off line evaluation new welders or processes.

Parameters that can be shown on the screen include:

Weld ID |

Time Stamp |

Welding Current |

Welding Voltage |

Wire feed speed |

Welding mode (process setup) |

Pulse Frequency |

Energy use |

Welding score |

Welding system alarms |

Welding Process Alarms |

Multiple System KPI’s |

The MQTT interface is completely compatible with the Xiris WeldStudio™ software utility.

Summary

Using MQTT with a Weld Camera can be a powerful tool for a variety of welding applications to enhance the amount of information that is displayed and recorded with the weld camera. Through synchronization, each frame in a video can be annotated with the power supply data at the time of acquisition, allowing for enhanced process and quality understanding of the welding operation.

Power Wave® is a trademark of The Lincoln Electric Company, Cleveland, OH, U.S.A.

.png)

.png)