Various pulsed synergic and non-synergic GMAW modes can be difficult to capture images of the processes due to the amount of light present in the image fluctuating considerably as the amperage varies and the arc flashes.

For example, a short circuit MIG process will generate a huge range in brightness during the metal transfer cycle: when the arc is extinguished and as the wire makes physical contact with the parent material prior to expulsion, the image can be quite dark. However, after an expulsion occurs and the arc is re-established, the image may be very bright as the arc intensifies to its maximum. As a result, using a weld camera to acquire images of this MIG weld process in free running mode becomes problematic. However, if the camera acquisition is signaled by a welding power supply to help synchronize the image capture, the result will be a consistent image of the weld process without any flashing.

(courtesy ESAB Group, Inc.)

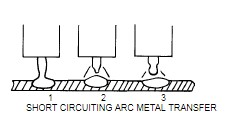

A few words about how Short Circuit MIG functions:

- Welding wire is fed continuously and makes physical contact with the workpiece to complete the electrical circuit.

- At the point of contact with the workpiece, a short circuit occurs.

- When this short circuit occurs, the voltage immediately drops to zero and the amperage increases simultaneously resulting in an explosion of spatter and a crackling noise that can be heard.

- At this point of the short circuit where the wire contacts the workpiece, the arc gets extinguished.

- The welding machine instantly reacts with a spike in amperage and the arc is reignited.

- This process repeats many times per second.

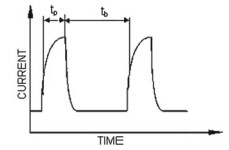

In a constant voltage welding power supply, the current being fed to the torch can rise and fall based on the metal transfer process. When there is a gap between the wire and the workpiece, the conducting current is low, and increases as the wire begins to touch the workpiece and create a short circuit. Then, once the wire tip explodes, the current falls as there is no conducting circuit. The plot of the current levels looks something like this:

(courtesy ESAB Group, Inc.)

While capturing the welding process to see certain features, it is sometimes interesting to only take images at a certain point in the metal transfer cycle. Rather than using a weld camera in free running mode where image acquisition is based on the clock cycles inside the camera, an efficient alternative is to use an external camera trigger kit that is based on the current levels present in the welding power supply. The Xiris Camera Trigger Kit can be used in combination with Xiris weld cameras to properly image advanced welding processes where large changes in brightness occur. The Camera Trigger Kit is used to sense the current from a welding power supply and generate an image acquisition signal to help synchronize the image capture with varying levels of brightness. Various pulsed synergic and non-synergic GMAW modes such as Surface Tension Transfer™1 or Cold Metal Transfer™2 can be imaged without flashing or the need to adjust camera settings. With stable and reliable image capture, operators can improve their process control with better quality and real-time analysis of the welding process, including the melt pool, seam, wire position or bead height.

Further enhancement to the performance of the imaging process is possible by tweaking exactly when the images are acquired through adding a delay. A delay can be added after the trigger signal is generated so that the exact imaging characteristic can be seen. Using the Xiris WeldStudio™ software, which is provided with each weld camera, operators have access to features such as positive- and negative-waveform edge detection, programmable delays, and a Trigger Mode setup with non-weld mode so that users do not have to keep turning on or off the Trigger Mode.

The above video shows the enhanced weld image that is captured when the Xiris Camera Trigger Kit is used in combination with the Xiris XVC-1000 weld camera.

In Summary

Imaging a MIG welding process can be difficult if using a weld camera in free running mode. However, Xiris’ easy solution for imaging pulsed welds can provide an excellent trigger to acquire consistent images at similar points in the metal transfer cycle. The result is much more uniform images with similar brightness levels, allowing for better analysis and increased efficiency of the welding process.

Better Images. Better Decisions. Better Process Control.

Follow Xiris on social media for regular updates and welding videos!

.png)

.png)