Introducing Xiris WeldStudio™ 3 and WeldStudio™ 3 Pro.

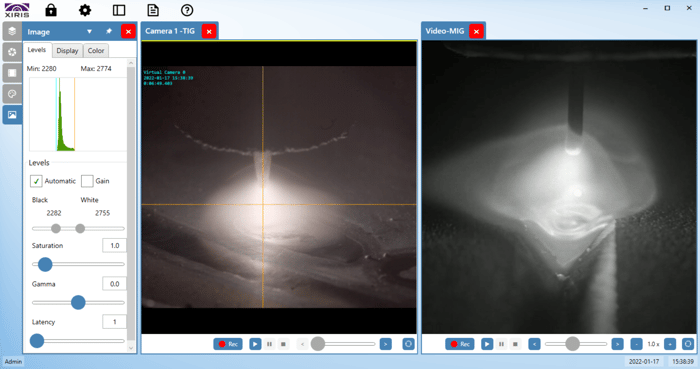

Weld monitoring of a process using a weld camera system can help verify that the best quality welds are being achieved. A key component in doing so is the accompanying software that supports recording, playback, and analysis of a weld.

We have recently released a new generation of software, Xiris WeldStudio™ 3 and WeldStudio™ 3 Pro developed in-house to ensure we are providing an easy and efficient solution for weld monitoring. Keep reading as we highlight a few of the features.

Permissions System

New to WeldStudio™ is the Permissions System that lets users create standardized and locked process settings to control a user’s ability to change settings within the software. With this feature, operator, technician, and admin modes can be set and password protected to help minimize any accidental changes to the software settings.

Recipe Management

Also included in Xiris WeldStudio™ 3 and WeldStudio™ 3 Pro is Recipe Management. Using Recipe Management, system settings can be set up, saved, and recalled with ease. Users can save and recall more than 100 different recipes and for multiple Xiris cameras. This added feature means set-up becomes effortless along with increased efficiency and accuracy.

More User Friendly

Primarily speaking, Xiris WeldStudio™ 3 and WeldStudio™ 3 Pro are more user friendly featuring an all-new modern interface and touchscreen friendly controls that can be used with any screen resolution or aspect ratio on any suitable HMI or computer. The newly designed interface presents on-screen navigation, larger touch targets and an on-screen keyboard making controls more easily accessible and recording and playback simple. As a result, less time is spent learning and remembering the software application and more time is spent monitoring whether on a large or small screen.

WeldStudio™ 3 Pro

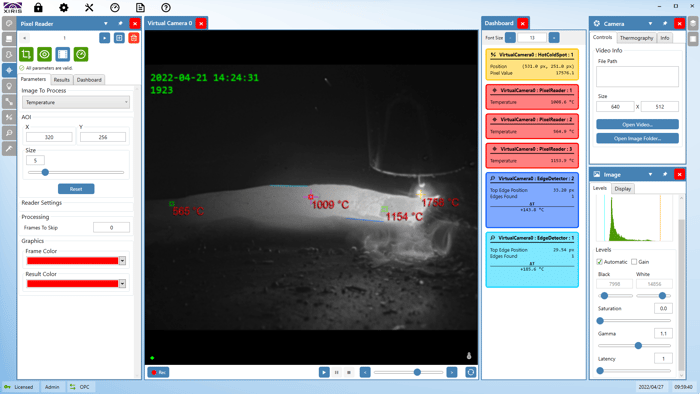

Go pro with Xiris WeldStudio™ 3 Pro version. Beyond all the same features as Xiris WeldStudio™ 3, the pro version features key measurement tools, machine vision tools and compatibility with several add-ons. Integrating visual, thermal, and audio information from a welding or metal additive process, WeldStudio™ 3 Pro can support a wide range of applications such as research and development or process monitoring on the production floor.

|

A Few Key Benefits:

|

To learn more about the additional features of Xiris WeldStudio™ 3 Pro, visit our website.

Weld monitoring just got easier. Request a demo with the software application to get started.

Stay up to date by following us on social media or subscribe to our blog!

.png)

.png)