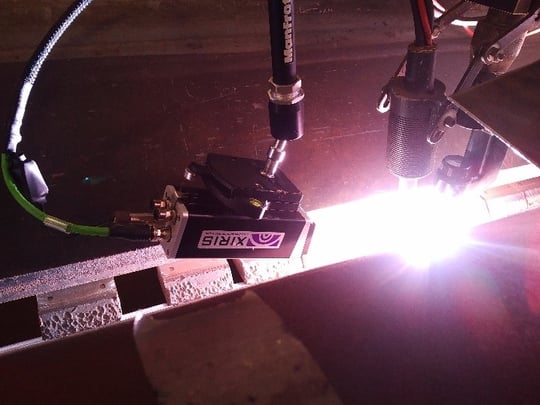

In the September issue (page 38) of Australian Welding, Weld Australia highlighted the progress Xiris has made in engineering high-dynamic-range (HDR) cameras that improve weld quality and efficiency.

We’re proud and gratified that Weld Australia recognized us. The organization has been a tireless proponent of the importance of welding, spreading the word that many industries wouldn’t be the same (or even exist) without welding.

All companies in those industries can benefit by using HDR cameras to monitor welding processes in real-time. Visual monitoring with eyes simply can’t match the clarity and certainty of a video record of the welding as it’s happening.

Australian Welding explains: “It is an enabling technology used across a wide range of industries and applications, from micro-joining of medical devices, electronics, and photonics to larger-scale applications such as mining equipment, pressure vessels, ships, rail transport, water pipelines, and components.

“Recent advances in advanced CMOS image-sensor design and supporting electronics allow best-in-class cameras to provide high-contrast images without saturation of the brightest portion of the image, exposing the details of the electrode, melt pool, seam, and surroundings.”

The article also details how remote camera monitoring benefits employees’ health and safety. Using weld cameras helps operators ergonomically because they’re not continually contouring their bodies to see the weld. They are also safer because they don’t have to be near the flame.

Another plus: videos of in-process welding can be highly useful in training and continuous improvement. It’s a technology that will attract and retain welding apprentices.

You can read the full article here.

.png)

.png)