Welding Automation can dramatically improve operator safety, productivity and weld quality. The trend to automate welding processes applies increasingly to large fabrication projects such as shipbuilding, maintenance and repair of petrochemical facilities, or in-situ welding of pressure vessels that typically require large numbers of skilled welders.

Welding SafetyEnsuring welder safety is a top priority for the fabricator in these types of projects. Using automated, or semi-automated welding equipment like weld tractors to perform long straight-seam welds can significantly reduce welder fatigue while improve weld quality. In addition, welding tractors often produce more consistent welds and are less likely to make errors during the welding process. However, they still require welding personnel to be present to be able to properly view and adjust the welding process, sometimes in constricted spaces, dangerous or uncomfortable positions.

|

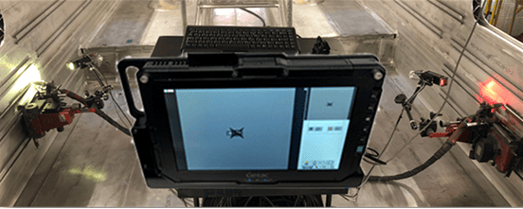

Xiris Portable Tablet HMI |

These projects require that the critical welds are all made on-site. This means any welding automation equipment needs to be portable, configurable and robust to be useful to the fabricator. By incorporating a weld camera, the fabricator can remove the welder from the immediate vicinity of the weld process, allowing them to monitor the welding process remotely, providing a health and safety benefit to the worker. Often the computer used to display video for such an application is a fixed HMI computer that is often panel mounted to a system electrical panel far away from the automation equipment. Monitoring the images from the weld camera on a fixed HMI computer reduces the ability of the operator from making quick process adjustments to the automation and the welding process, especially if the weld seam is very long, e.g. more than 30m / 100’ in length.

The Solution

A better solution is to use a tablet computer that allows operators to stay removed from the immediate hazardous area of the welding process but still maintain a clear view of the welding process in real-time while being able to walk or move a few steps behind the welding automation equipment. By using a tablet HMI, welding operators can focus on making good quality welds and react more efficiently to process problems that may develop.

Xiris Portable Tablet HMI can be used with Welding Tractors

The Xiris Portable Tablet HMI, in combination with a Xiris weld camera, provides a robust portable weld monitoring solution suitable for almost any harsh welding application. The modular design allows for easy setup of the weld camera system within minutes for virtually any automatic welding process so that operators can monitor their process with confidence up to 100M (330ft) away.

To inquire about incorporating the Xiris Portable Tablet HMI into your welding process, contact us.

.png)

.png)