Laser Hybrid Welding (LHW) is a beneficial material processing application for many fabricators because it can produce high-quality welds at higher welding speeds, with less power use. But it also demands an extreme precision that necessitates detailed, real-time monitoring of the weld process.

Advanced Weld Cameras can provide this level of monitoring, allowing fabricators to gain the advantages of the laser hybrid process without any sacrifice in productivity or quality. On the contrary, Weld Cameras with High Dynamic Range imaging can improve output and quality control.

The Laser Hybrid Welding (LHW) Process

LHW combines certain aspects of open arc welding (including MIG, TIG or Plasma Arc) with Laser Beam Welding (LBW) to produce results that neither process can accomplish alone, particularly an increase in both weld penetration depth and welding speed.

Laser Hybrid Welding

LHW is most widely used in the manufacturing of automobiles, ships, rail cars, and shipping containers, as well as in the construction industry. But it’s likely it will be increasingly used for other applications as well, due to factors such as the:

- Higher deposition rate of the LHW process.

- Increasingly lower power consumption compared to conventional systems (Fiber lasers, for example, use only one-third the power of traditional CO2 lasers, which already used less power than conventional arc welding processes).

- Increased demand from customers for higher quality welds with higher weld penetration.

- Improved capability to prefabricate parts to the tight tolerances required for laser welding.

- The availability of better process monitoring solutions than ever before.

Why Weld Cameras Are Needed

The best automated LHW systems have high-accuracy, large-scale gantry kinematics; rugged, precise optics; and effectual offline programming. But to truly achieve a state-of-the-art level of manufacturing, LHW systems also need integrated Weld Cameras that allow the operator to monitor the process in real-time. This process visibility allows operators to use their experience and judgment to make necessary adjustments to maximize productivity and quality—adjustments that automated seam trackers can’t make on their own.

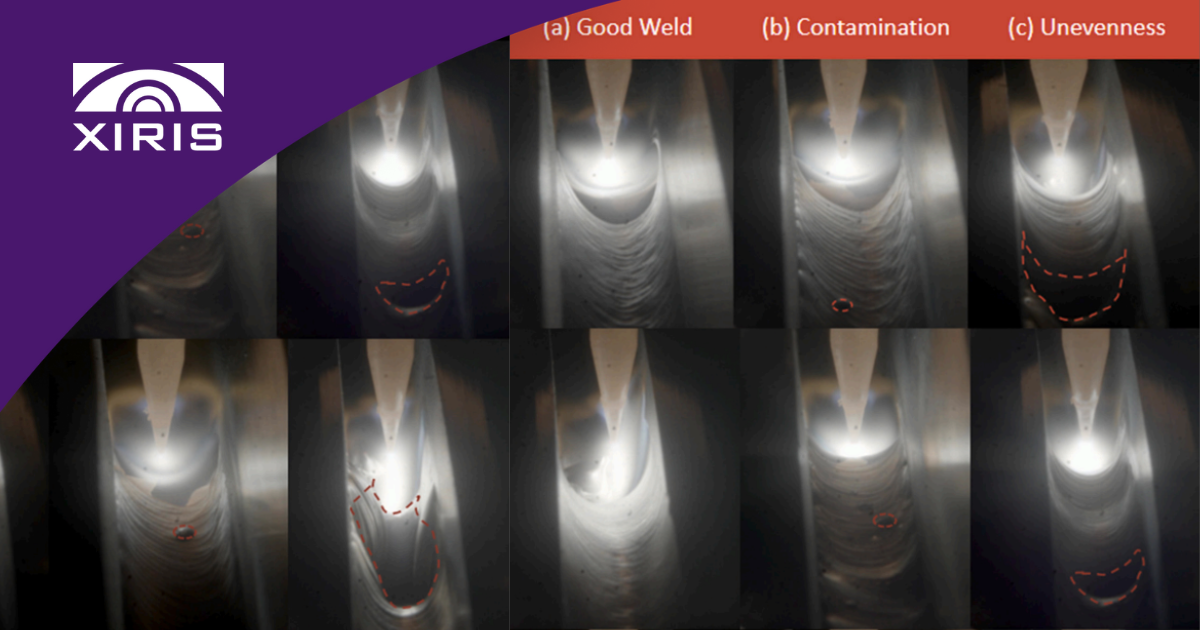

This capability is a relatively new development. The effectiveness of Weld Cameras has traditionally been limited due to the inability of standard cameras to provide a clear image of both the super-bright arc (particularly the spot of a laser) and the dark surrounding background.

In arc welding such as MIG, more than 120 dB of dynamic range of imaging is usually necessary to view the entire weld scene with enough detail to be helpful to operators—and in laser beam welding even more dynamic range is required. To clearly view the entire weld scene using a standard camera—which can only image a brightness range of about 50-60 dB— operators had to image the arc region and then stop the process to switch the camera’s aperture to image the dark background.

However, the development of High Dynamic Range imaging technology has overcome this technical barrier. Weld Cameras with High Dynamic Range imaging (e.g., the Xiris XVC-O) can image a brightness range greater than 120 dB, and when integrated into a LHW system they provide the fullest possible process and quality control.

Conclusion

For OEMs, integrating Weld Cameras with High Dynamic Range imaging into their LHW systems is essential to creating a high-quality, high-speed, state-of-the-art welding cell. End users can also gain a competitive advantage by being able to better monitor the high-quality welding process, providing better process control. The net result is that they can leverage their investment in a LHW system to achieve better results.

Image courtesy of N. Hoeppe & G. Van Antwerp, Industrial Laser Solutions/PennWell, 9/13.

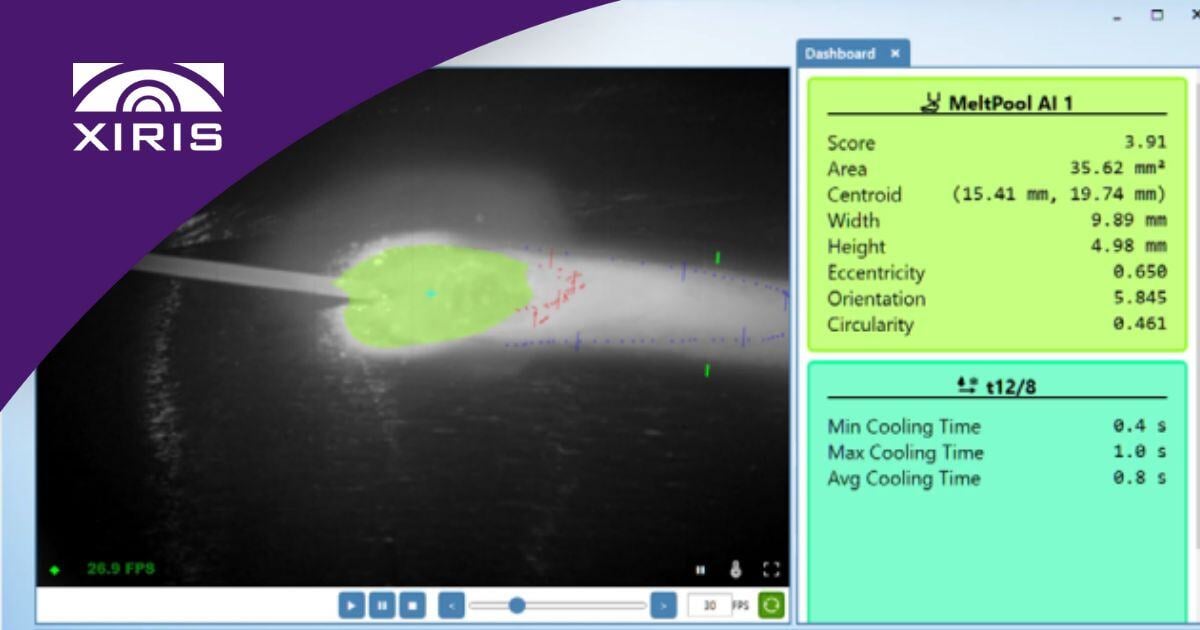

Here is an example of a weld camera capturing a laser hybrid welding process. For more videos like this please visit our Welding Video Library