Welding is one of the most critical processes involved in the global manufacturing industry, essential for joining and fusing material to create strong and reliable structures. The quality and integrity of the weld can be ensured by monitoring the weld penetration into the parent material. Due to its dynamic nature and high temperature, directly observing the welded joint, especially the liquid-solid interface, can be challenging.

In past, sensors were used to gather welding data from the gas-liquid interface, providing operators with an indirect inference of the penetration site.

Welding can be an inherently complex process. Achieving consistent and precise monitoring of that welding process involves at some point, detecting, measuring and tracking the weld arc and melt pool during an active weld, using tools such as weld monitoring cameras. However, varying material metallurgy, fluctuating input power parameters, shielding gas composition and wire quality and placement are just some of the variables that can make accurate monitoring difficult. To overcome these challenges, advanced technologies like thermal imaging and real-time data analytics are revolutionizing the welding field and empowering welders to achieve unparalleled understanding of their processes.

How Advanced Monitoring Technologies Can Improve Welding Processes

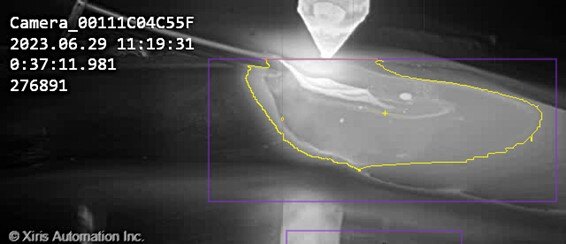

Thermal imaging can provide a whole new level of understanding the welding process. By combining a good quality thermal image with appropriate machine vision tools, weld features such as the melt pool, torch tip quality and cooling weld bead can be imaged and analysed effectively despite the variations in light and heat present in a typical welding environment. Machine vision technology enables feature and data extraction from an image so that shape analysis, edge detection, pattern matching and temperature analysis can used to characterize the features of the weld.

For example, with machine vision, the melt pool boundary can be identified by segmenting its temperature characteristics from the rest of the welding scene. Once segmented, specific geometric parameters of the resulting melt pool region, such as shape, area and position can be measured and tracked as the melt pool moves or morphs its shape. This is particularly valuable when the melt pool can still be detected under complex situations when factors such as confined space, limited lighting and camera angles vary.

|

Employing Machine Vision and AI for Smarter Welding Solutions

Despite significant advances in using classical machine vision for welding processes, several challenges persist. The initial step in using classical machine vision to identify the object in a welding scene that needs to be tracked, typically the arc, the seam and the melt pool, can be challenging as the light intensity of all those features may be similar enough to cause fewer or greater pixels to be classified as part of each object.

In machine vision, multiple algorithms work together to detect and track objects in a video. This approach is effective in most cases, but in the case of a melt pool, the technique struggles to detect the ellipsoidal shape due to insufficient colour or contrast differentiation between the puddle and the surrounding metal. To address this, additional techniques such as edge-detection, noise reduction and image averaging can be employed to track and record the melt pool effectively.

Such machine vision techniques can improve the object tracking, making it more precise, even if the object is partially or fully obscured, simplifying measurement after identifying the puddle.

However, in certain situations, better techniques are needed to find the extent of a melt pool whose boundary is hard to find. That's where AI comes in.

AI-Driven Insights for Enhanced Weld Monitoring and Parameter Optimization

Traditional Object detection processes rely on identifying differences in brightness levels between an object and its background, or finding edges of the object where they exist.

The high-temperature environment of welding further complicates the direct observation of the liquid-solid interface with computer vision. To overcome this, thermal cameras are used to collect 2D images of the temperature of a scene. With such images, object segmentation is definitely easier than with only visible light imaging.

However, even the best classical machine vision techniques are not able to segment all features all the time.

AI (Artificial Intelligence) techniques can be employed to enhance the quality of the segmentation of the scene for better data extraction. In addition, other top-side sensors can be used to collect raw data from the weld interface.

This indirect method involves identifying phenomena that correlate with penetration state variables, such as incomplete penetration, penetration depth, and back-side bead width.

To enhance model predictions using AI, multiple data sources are required, particularly where the complex welding processes, material properties, temperature variation and other welding parameters are constantly changing. These sources can include melt pool reflection images, active pool oscillation images, and temperature fields. Integrating and analysing all of the data sources with an AI processing engine provides a more comprehensive and complete overview of the welding process.

.png?width=1380&height=745&name=Melt%20Pool%20Segmentation%20and%20Measurement%20in%20WeldStudio%20(Xiris).png)

|

Case Study: Real-Time Weld Penetration Monitoring with AI/Deep Learning

Rui Yu et al., from the University of Kentucky, United States conducted a recent study demonstrating the effectiveness of AI/deep learning-based real-time monitoring on weld penetration. The researchers have highlighted the need for dynamic adjustment of welding parameters and the difficulty of real-time in-situ monitoring due to the non-observability of the penetration state during the welding process.

The data set used in the paper was comprised of thermal images of the welding process. These images were processed using deep learning algorithms to identify and track the melt pool's contours and temperature patterns with promising results. This study underscores the potential of thermal welding cameras in enhancing weld penetration monitoring through superior image quality and real-time data processing.

Conclusion: Elevating Weld Quality through Cutting-Edge Monitoring Technologies

SWIR thermal camera technology, classical machine vision and AI technologies are revolutionizing weld accuracy, performance, and overall quality. The challenges posed by detecting and tracking the welding arc and molten puddle underscore the uniqueness of each machine vision application. Techniques that are effective in one scenario may be inadequate in another, highlighting the importance of a comprehensive understanding of various machine vision algorithms and their specific use cases. By leveraging SWIR thermal camera technology and advanced temperature pattern detection, modern welding systems can achieve unprecedented levels of reliable “arc-on” performance, ensuring high-quality welds and enhancing overall productivity in manufacturing

References

Yu, R., Cao, Y., Chen, H., Ye, Q., & Zhang, Y. (2023). Deep learning based real-time and in-situ monitoring of weld penetration: Where we are and what is needed revolutionary solutions? Journal of Manufacturing Processes, 93, 15-46.

Stay up to date by following us on social media or subscribe to our blog!

.png)

.png)