Capturing high-quality images of aluminum can be quite challenging due to various factors. However, in this video, we get a special glimpse into the Fronius CMT welding process, showcasing the intricate details of this technique captured using a thermal camera.

Imaging aluminum welding is particularly tough because the metal is so highly reflective, has a significantly lower melting point than other metals, typically around 660°C, and dissipates heat very quickly once welded. As a result, it can be very tough to get good images of aluminum welding processes.

To accomplish this feat, a Xiris XIR1800 camera specifically calibrated for aluminum was used to acquire thermal images of the welding process. The camera was equipped with a filter precisely calibrated to measure temperatures up to 1000°C and work with a very short exposure time of about 0.5 ms, which is ten times faster than the standard exposure time of 5 ms.

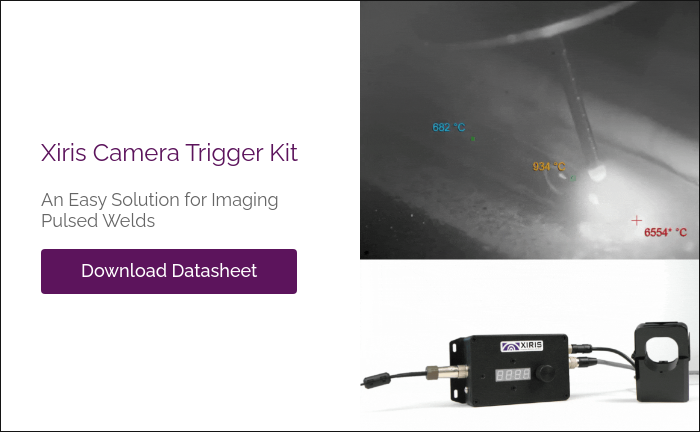

To ensure that the best, most stable images of the GMAW welding process were captured, a Xiris Voltage Trigger Kit was used to synchronize the image acquisition to the waveform of the welding power supply.

This enabled precision timing for capturing the portion of the metal transfer that was of greatest interest to the viewer. The video above starts with image capture running with no trigger. The resulting image is variable, with lots of variation in brightness due to the GMAW expulsion.

About 8 seconds into the video, the voltage trigger was turned on and set to trigger at a specific point in the power waveform to allow the camera to image the "No Arc" condition.

This allowed image acquisition to occur when no arc was present, providing an accurate representation of the welding process. The difference in image quality is dramatic, highlighting how effective the trigger signal is in creating a stable video from the thermal camera.

In the above video, the wire used in the process was 1.2mm in diameter and the welding speed was about 5 meters (200”) per minute on a flat aluminum plate.

When examining the resulting videos, several essential elements become apparent once the triggering takes effect.

Firstly, the wire itself is clearly visible, along with its heated molten tip because there is no flashing arc.

Additionally, there is a distinct outline of the melt pool, showcasing the precise boundaries of the liquefied aluminum.

The image also reveals the extent of the mushy zone, where the melt pool transitions into a semi-solid state.

The cooling bead is also clearly depicted, representing the solidification of the molten aluminum.

Lastly, the image provides a clear view of the base material and the effective cleaning zone of aluminum oxide prior to welding, emphasizing the meticulous preparation required for successful aluminum welding.

By using the advanced technology of the XIR1800 thermal camera combined with a Voltage Trigger to acquire precisely timed videos, the above video provides a clear insight into the complex world of aluminum welding and all its parameters.

It showcases the remarkable capabilities of the XIR1800 thermal camera when used with the innovative Voltage Trigger Kit to create synchronized video.

Conclusion

The above video not only highlights the intricate details of the Fronius CMT welding process in action on aluminum, but also emphasizes the importance of using a precise image trigger with a thermal camera to capture the best possible images of aluminum welding.

.png)

.png)