Artificial Intelligence (AI) is changing several industries, and welding is no exception.

In the world of welding, there are numerous factors that can lead to weld defects, such as inconsistencies in the base metal chemical composition, humidity in the welding wire, oil or paint contamination, lack of shielding gas, incorrect welding parameters, and even incorrect torch angle.

These factors can have a significant impact on the quality of the weld and can result in costly rework and repairs.

To address these challenges, Xiris has developed a groundbreaking solution called MeltPool AI. This innovative tool leverages the power of machine learning to automatically identify and segment the weld pool from the rest of the image captured by a weld camera.

By accurately distinguishing the pixels that belong to the melt pool, MeltPool AI enables precise measurements of the size, shape, location, and other geometrical parameters of the pool.

|

|

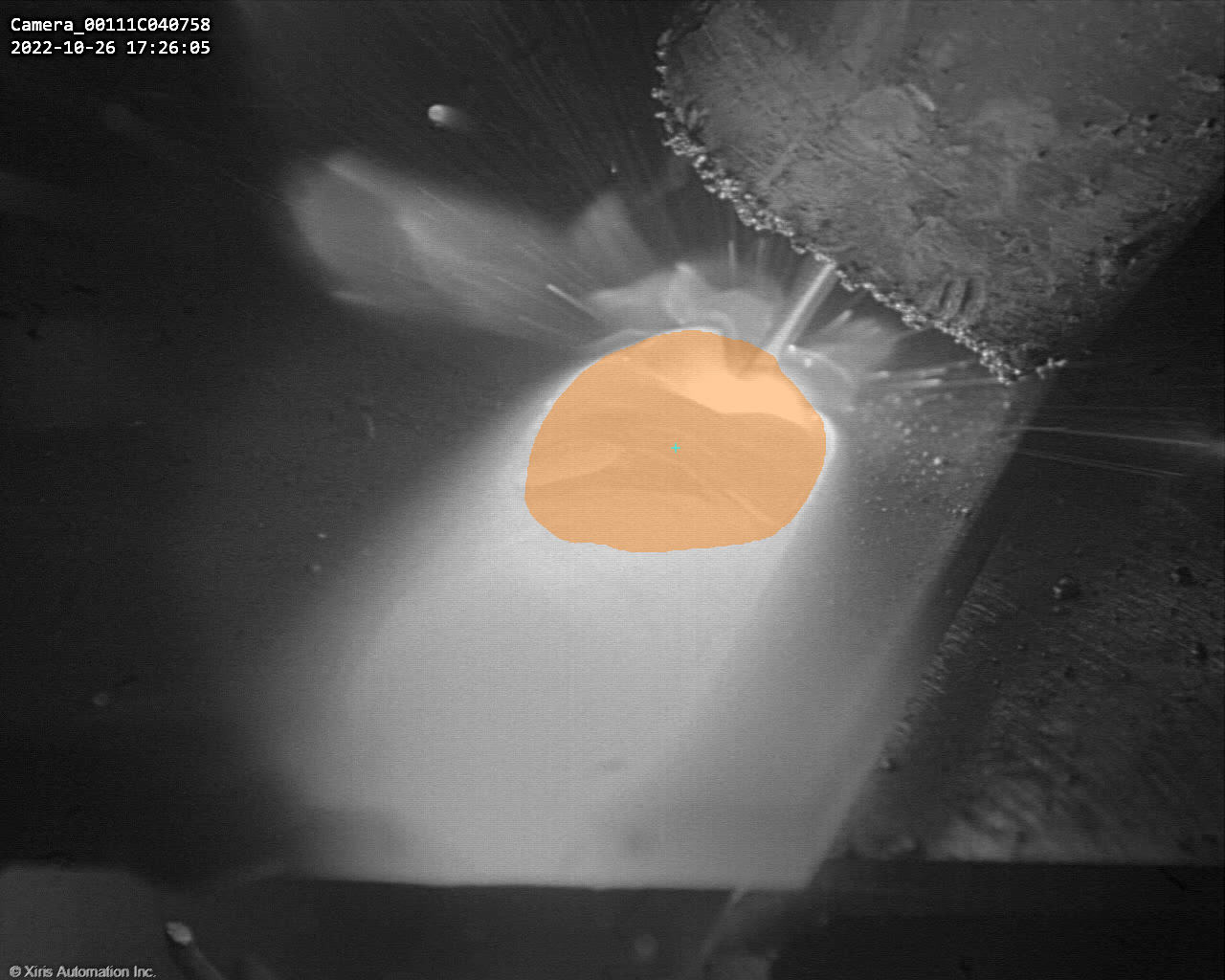

GMAW Melt Pool before (left) and during (right) a burn-through defect. The change in the melt pool geometry is instantly detected by MeltPool AI, allowing for better Defect Detection.

The melt pool is influenced by variations, and even small changes can indicate defects. Real-time measurements from MeltPool AI help detect and prevent defects, saving time and ensuring weld quality.

MeltPool AI's effectiveness is demonstrated in the figure below, where excessive heat input during the welding of sheet metal caused a burn-through of the weld. The tool detected the change in the shape and size of the melt pool, highlighting its high sensitivity to even the smallest variations. This greatly enhances defect detection techniques and leads to improved welding outcomes.

By leveraging machine learning algorithms, welders and inspectors can accurately measure and analyze the melt pool, enabling them to identify and address potential issues in real-time. This technology not only enhances the overall quality of welding but also saves time and resources, leading to improved productivity and customer satisfaction.

Discover the in-depth insights in our exclusive whitepaper: Why Melt Pool Analysis is Important for Automated Welding

Stay up to date by following us on social media or subscribe to our blog!

.png)

.png)