Guaranteeing the quality and efficiency of an automated welding process requires an operator to watch the process and make occasional adjustments as necessary.

But regardless of the type of welding process, most open arc welding systems create an enormous amount of light during their operation. Viewing an open arc welding process for just a few seconds with the naked eye can cause specific, and often irreversible, eye damage.

This harm can be prevented if the operator uses a welding helmet with a special optical filter to suppress enough of the damaging brightness coming from a weld arc to protect the eyes. But this solution creates productivity and quality-control problems because the optical filter on the welding helmet keeps the operator from seeing the “whole picture”—leaving only the brightest features of the weld tip visible. As a result, the operator can’t sufficiently determine what’s happening in order to make appropriate in-process adjustments.

Limitations of the Human Eye

Without the welding helmet’s protective filter, the visibility range provided by the human eye would prove inadequate for weld monitoring. Typically, a weld tip might be as much as 10 million times brighter (greater than 140 dB brightness ratio) than the background metal area around it. This is a much wider visual range than a human eye can see, even if it could healthfully stand such light exposure.

A human eye has a built-in iris to adapt to a large range of light, about 1,000,000:1. However, it limits out on extremely bright light, which is why looking at the sun can damage the eye. Direct sunlight at zenith (directly overhead) as viewed through the atmosphere has about 150,000 candelas per square cm (cd/cm2) brightness.

While the sun is a bright-enough light source to cause damage to the human eye with continuous exposure, some artificial light sources—such as Xenon arc lights used in some high-discharge bulbs—that can generate even brighter light, namely up to 500,000 cd/cm2 of brightness.

And the welding arc from a high-powered open arc welding torch can produce even higher brightness, especially in a short circuit mode MIG weld process. Certain welding arcs are brighter than almost all other known light sources familiar to physical and industrial applications.

Safety and Visibility Both Needed

Recognizing the risks of manual monitoring of automatic welding processes even when the operator is properly attired with suitable clothing and a welding helmet, many manufacturers have adopted some form of Weld Cameras to remove the necessity of welders being close enough to the weld to see it with their welding helmet.

But this solution doesn’t necessarily overcome the weld visibility issues: If a standard, off-the-shelf camera is used, it may not be able to provide the image detail necessary for properly monitoring both the weld and its surroundings. In fact, sometimes even less information is provided to the operator than if the operator was monitoring the process directly via a welding helmet.

Seeing the Entire Range

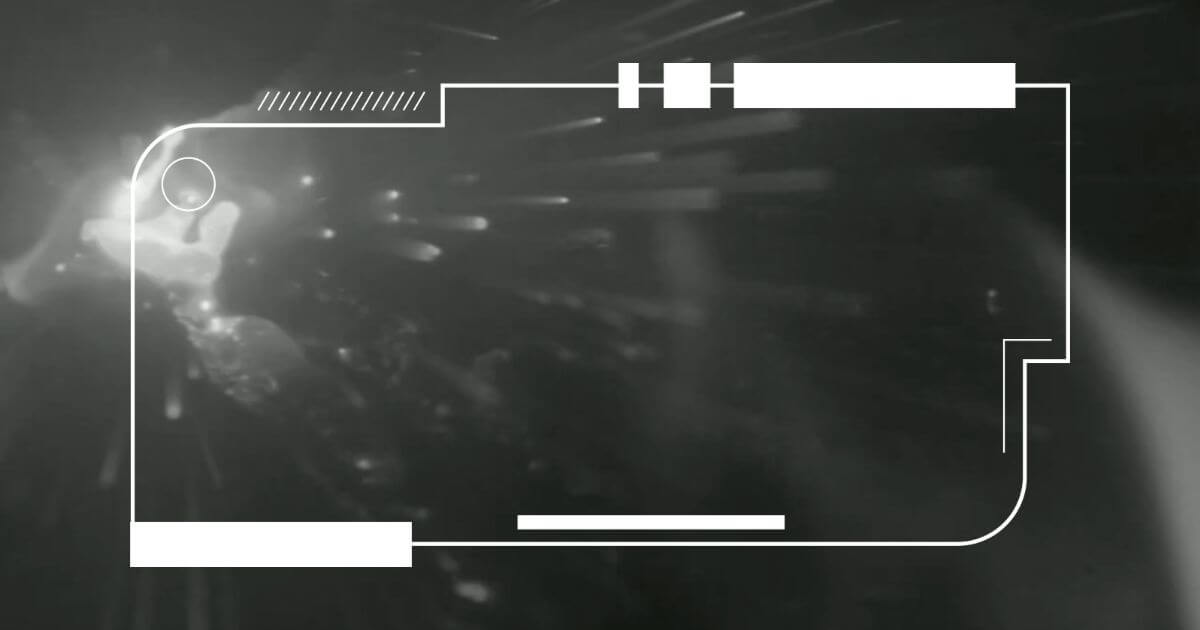

A Weld Camera equipped with High Dynamic Range imaging technology, such as the Xiris XVC-O, improves image quality to the point that operators can see the weld and its environment much better than what is possible using a welding helmet, while removing the operators from proximity to the welding process.

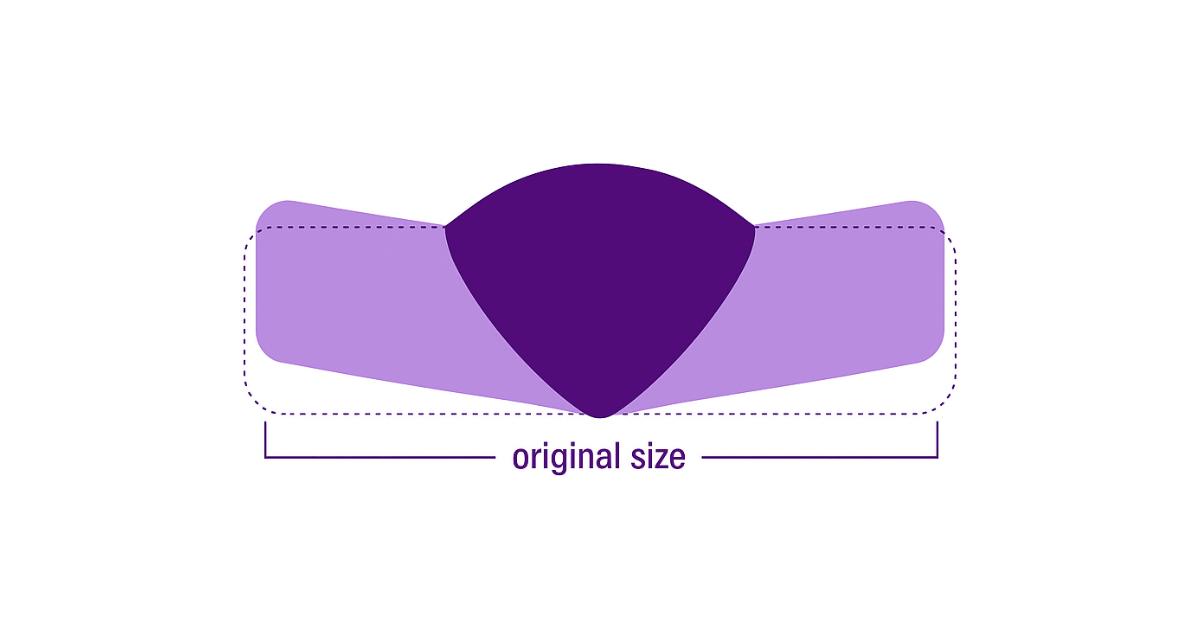

Most cameras today are capable of only about 50-60 dB signal-to-noise ratio (about 1,000:1 dynamic range of brightness). But a Weld Camera with High Dynamic Range imaging is capable of more than 140 dB, allowing the operator to see both the very bright light source of the weld arc, as well as the dark area of its immediate weld environment.

Weld Cameras can be mounted at the weld tip, before or after the tip, to see all the features of a weld. The XVC-O Weld Camera uses a logarithmic sensor to achieve its High Dynamic Range imaging capability. The output of the camera is fed into image processing software to further enhance the weld image quality. The resulting images have a clarity of contrast and level of detail that surpasses what a standard camera can hope to achieve—or what a human eye can possibly make out.

Conclusion

Not only is it a health risk to rely on manual monitoring of automatic welding processes; the human eye lacks the dynamic range or tolerance of bright light to monitor welding. Even with the use of a powerful filter on a welding helmet, manual monitoring is no match for modern Weld Camera technology in creating high-quality images of a weld. And using a Weld Camera to perceive the detail necessary to adequately guide in-process adjustments is much easier than using any other monitoring method.