Welding instruction is vital to ensure that operators are capable of overseeing automated welding applications in a way that results in high-quality products and process efficiency.

But picture a brand-new welding school, designed to educate welders about new equipment and processes, as well as the basics of automated welding that have been long proven to work. This school has state-of-the-art facilities and expert faculty. It sounds great right?

However, it could fail in its mission because of a simple problem—it’s hard for students to see the actual welding that’s being demonstrated. In typical weld instruction, the weld area is small compared to the classroom in which it’s being shown. Instructors and other students can easily get in the way. And if anything is missed, there’s no way for the student to review the presentation.

The most critical aspect of welding instruction is being able to see the actual welding process taking place, but the logistics of how to provide students with that weld view are a challenge.

Weld Cameras: The Future of Weld Visibility

The solution for welding instruction is the same solution that fabricators are increasingly employing in their operations—a Weld Camera to provide images of the weld so that weld monitoring can be done at a safe, remote distance.

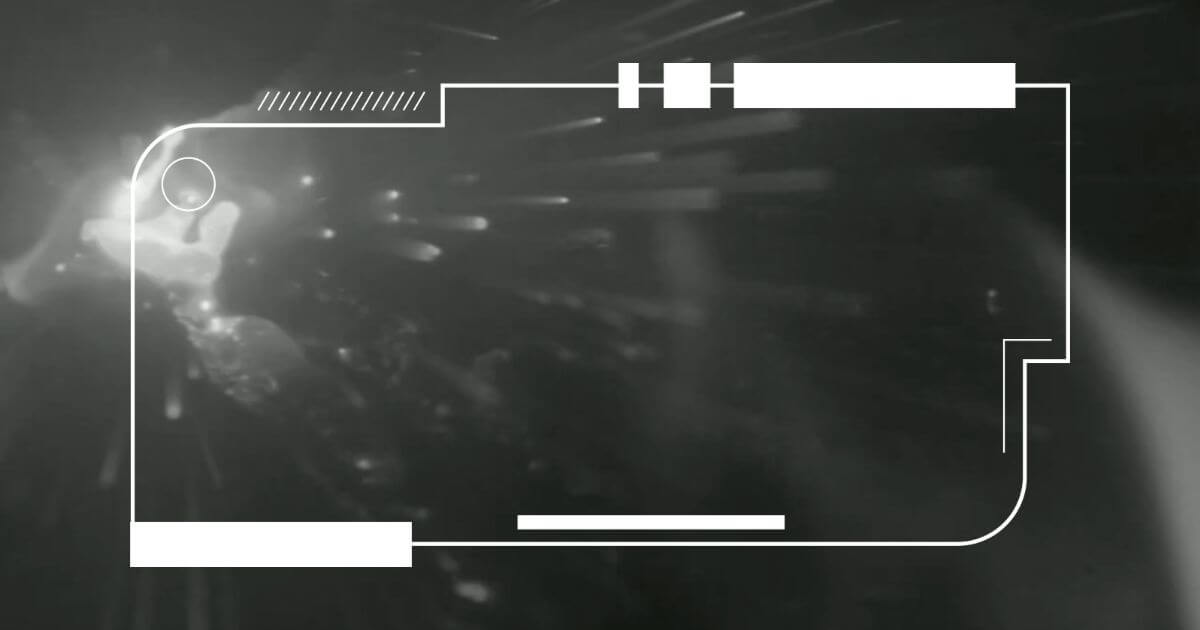

In the classroom, this monitoring is for learning purposes, and the visibility provided by a properly-equipped, well-designed Weld Camera elevates welding instruction to a new level. With the advanced High Dynamic Range imaging technology now available on Weld Cameras, students can see in real time on a display monitor what’s happening with a weld, without everyone having to crowd around the weld area.

Welding processes such as MIG, TIG, Laser, and Plasma welding can be observed in high detail. Students can clearly make out critical elements, including the torch tip, material flow, melt pool, edge presentation, keyhole, seam, gas barrier, and weld undercut.

Welding processes such as MIG, TIG, Laser, and Plasma welding can be observed in high detail. Students can clearly make out critical elements, including the torch tip, material flow, melt pool, edge presentation, keyhole, seam, gas barrier, and weld undercut.

And when the instruction is over, video of the weld images throughout the entire demonstration is available so that students can review it at their convenience, as often as it takes for the key lessons to be absorbed. Both good and bad welds can be analyzed, learned from, and archived for future reference.

And, importantly, using Weld Cameras in the classroom familiarizes students with the use of cameras in welding. Weld Cameras are clearly an integral part of the future of welding automation, so this early exposure to them is valuable.

High Dynamic Range Makes It Work

Don’t underestimate the importance of having the right technology on a Weld Camera used in welding instruction. Fabricators sometimes try to up-fit standard, off-the-shelf cameras to make them suitable as Weld Cameras. The problem is that—even with digitization software and physical modifications to allow the cameras to withstand the harsh welding environment—standard cameras aren’t able to overcome the imaging challenge produced by the extreme range of brightness between an open arc and the dark surrounding background.

The weld arc is more than 10 million times brighter than the background metal, but most standard cameras can only image a dynamic range of brightness of about 1,000:1 (50-60 dB). To gain the full advantages of a Weld Camera in welding instruction, the camera needs to have more than 140 dB of dynamic range—a range that can only be supplied with advanced High Dynamic Range imaging technology such as you’ll find on the XVC-O Weld Camera.

Conclusion

A Weld Camera with High Dynamic Range imaging capability can enhance welding instruction, creating a more-enjoyable, more-effective learning experience. Techniques and applications can be better illustrated, images of lessons can be preserved, and students can use the weld images in support of their technical projects and research.

So, are you ready for weld cameras in your classroom?

Visit our website, download our Education Whitepaper or contact our Education Account Manager for more information

Better Images. Better Decisions. Better Process Control.

Follow Xiris on social media for regular updates and welding videos!