With advanced camera design and image-processing technology, the latest Weld Cameras can provide manufacturers with a valuable video record of their automated welding processes.

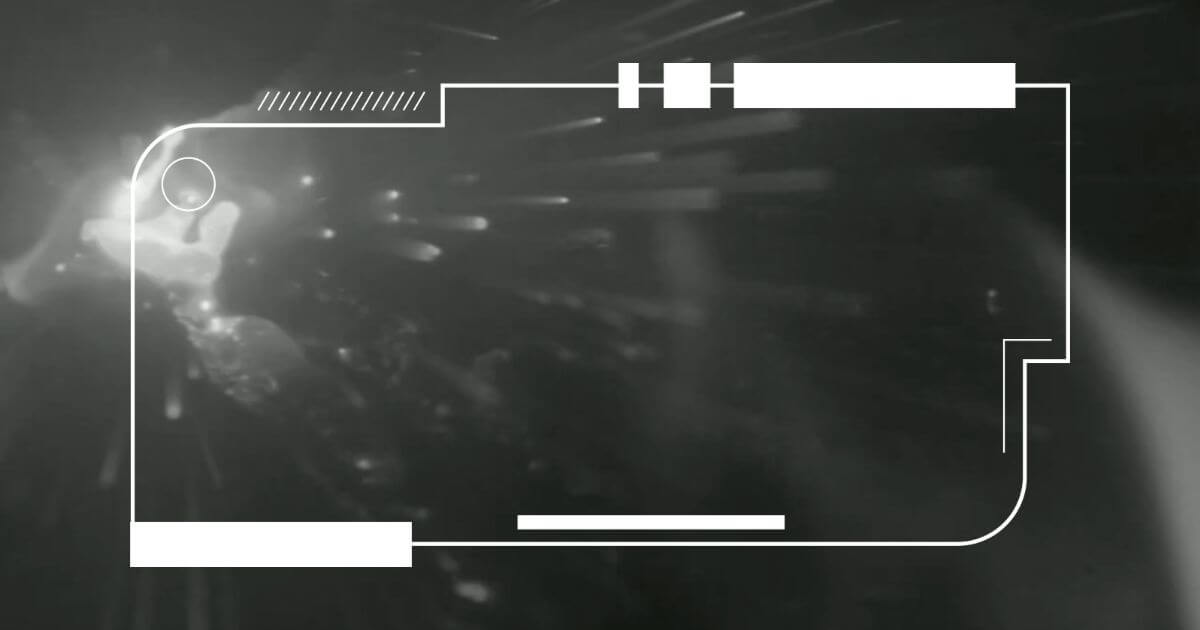

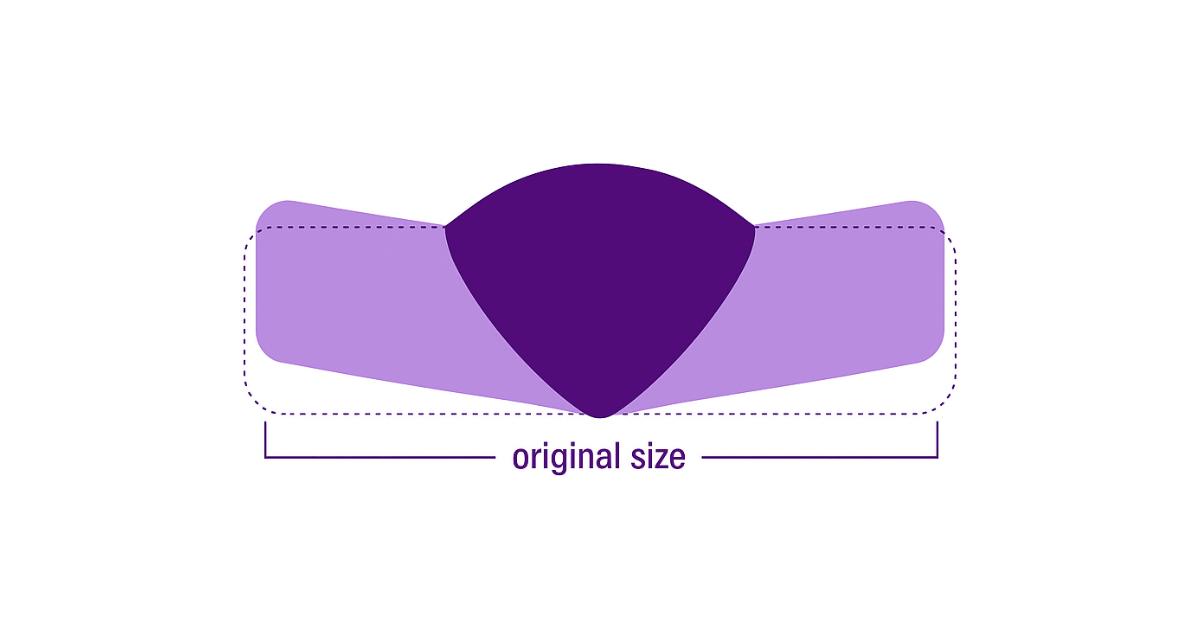

The latest technology in camera design makes possible High Dynamic Range imaging, which means the displayed and recorded video will have good detail of both the super-bright region of the open arc and the darker area of the surrounding environment.

The latest technology in camera design makes possible High Dynamic Range imaging, which means the displayed and recorded video will have good detail of both the super-bright region of the open arc and the darker area of the surrounding environment.

While the ability to display better quality images is key to improving productivity during set up and run time, the capability to record and play back high-quality video of live weld scenes is useful to fabricators in several important ways.

Troubleshooting

The video record is a time-based log of the welding process that can be used to quickly pinpoint the cause of defective welds, allowing the problem to be corrected before it becomes a costly, recurring issue.

Less Final-Inspection Cost

Because the video enables precise detection of where a process went wrong and is precisely timed, only that portion of the weld where a defect is detected in the reviewed video requires a final inspection.

Continuous Improvement

Auditing the videos offline, fabricators can verify their welding processes and assure quality to both internal and external stakeholders, while identifying opportunities to improve quality and efficiency.

Training

Trainees can learn from videos of both successful and problematic welds by being able to see all the critical aspects of the process on a display screen away from the welding process. There’s no need to crowd around an actual weld to see crucial details such as the torch tip, material flow, melt pool, edge presentation, keyhole, seam, gas barrier, and weld undercut.

After class, trainees have the benefit of being able to watch the video at their own convenience to get the full lesson.

Using a Weld Camera with High Dynamic Range imaging for operator training also helps familiarize trainees with this important new technology—knowledge that will them maximize the value of its use.

Conclusion

Weld Cameras with High Dynamic Range imaging, such as the Xiris XVC-O, are capable of producing a video record of automated welding that can help fabricators lower costs, improve processes, and better train operators.