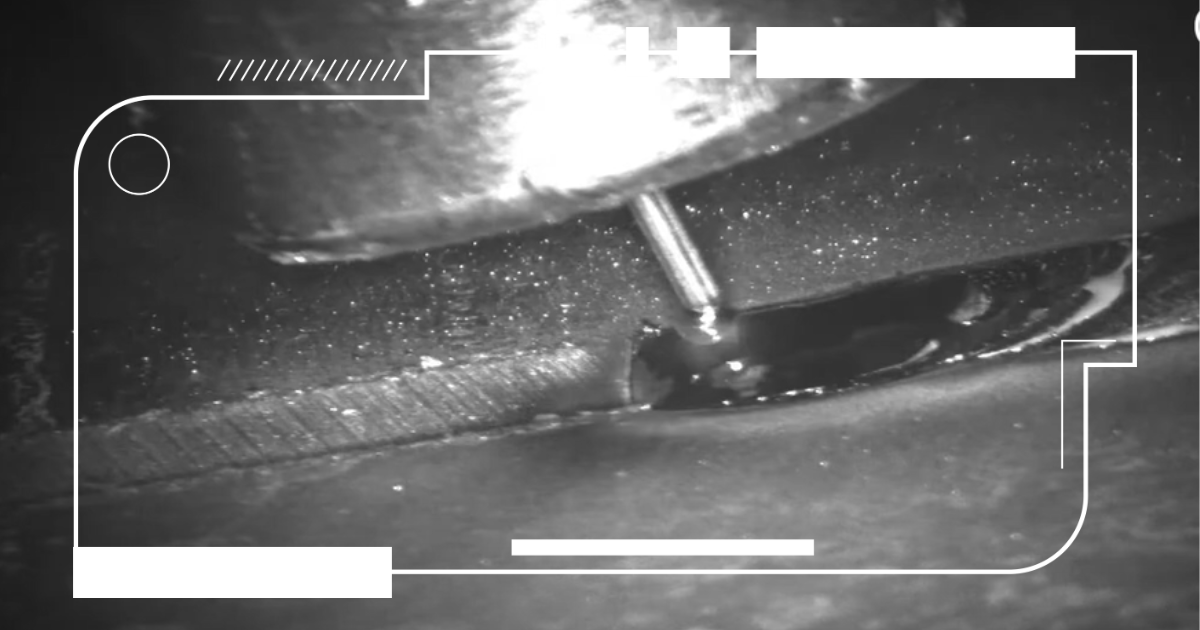

Some welding applications must be done in high-humidity conditions that can cause problems for Weld Cameras.

Because of the heat around the weld arc, a Weld Camera must be cooled during operation. In a high-humidity environment such as a jungle location, the high humidity results in condensation forming on the lines that flow cool air into the camera to accomplish the cooling. If the Weld Camera isn’t waterproof, the condensation can run along the air lines into the camera’s electrical components, causing shorting or oxidation.

Outdoor welding is a common reason for high humidity. In addition, other types of welding such as that done on Tube or Pipe mills, where a large amount of water/oil coolant is used, also create high humidity around the weld camera.

Outdoor welding is a common reason for high humidity. In addition, other types of welding such as that done on Tube or Pipe mills, where a large amount of water/oil coolant is used, also create high humidity around the weld camera.

Whatever the cause, when using a Weld Camera in such an environment, a sealed housing to waterproof the camera is essential for ensuring long-term operation.

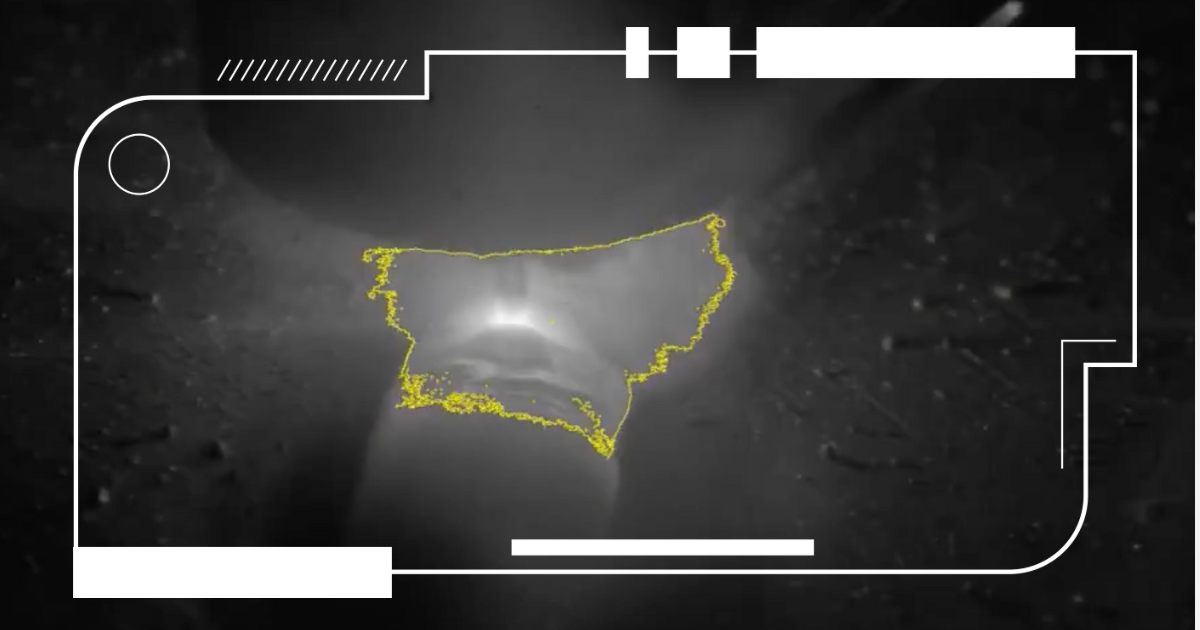

For the Xiris XVC-O Weld Camera—which features state-of-the-art High Dynamic Range imaging to help operates better see critical details of a weld—we designed a rugged, enclosed housing that’s IP67-rated and therefore able to resist water, smoke and other ambient particulates found in the immediate area of a weld process.

We recently visited a customer site where this sealed housing was desperately needed. The customer was welding in Southeast Asia—a jungle environment where the humidity was 100 percent and the ambient temperature was a steamy 35° C (95° F). Predictably, they had a problem with condensation running down the cooling lines used to cool their production equipment.

However, the Weld Cameras stayed completely dry and functioning properly despite the fact that they were covered in moisture. The water-resistant housing allowed the customer to gain the many advantages of XVC-O Weld Cameras, without putting the cameras at risk of damage in a high-humidity environment.

Conclusion

Welding in adverse environmental conditions such as high humidity does not mean that you can’t use a Weld Camera without subjecting it to harmful water exposure. Xiris’ XVC-O Weld Camera can safely and effectively operate in the most-humid environments in the world and has the experience to prove it!

Image courtesy of Muffet, Creative Commons.