Coaxial Mounting of a Weld Camera onto Laser Processes

A High Dynamic Range Weld Camera can provide great benefit to a laser welding or cutting process by allowing examination of the melt pool and seam while the laser is on. In this blog we explore one method of mounting cameras to the laser welding or cutting process: Coaxial or On-axis mounting of the camera.

In coaxial mounting, the camera is mounted parallel to, and pointing in the same direction, as the laser source. The image delivery optics for the camera are combined with the laser beam delivery optics via a beam splitter so that the camera shares part of the final optical path through which the laser beam travels.

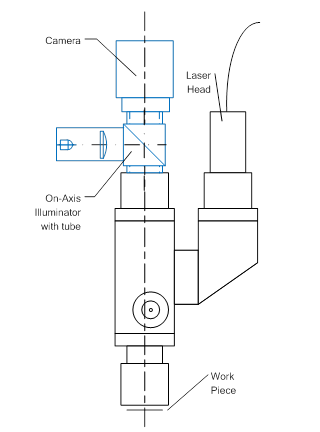

A depiction of an On-axis camera mount configuration is presented below. In this configuration, the camera has the straight through optics while the laser beam is coming in from the side via a beam splitter.

On-axis camera mounted to laser beam delivery system

There are both advantages and disadvantages to this type of camera set up on the laser process.

Advantages:

- Results in a small form factor package that can be tightly integrated into the laser optics head.

- Operator is able to see the weld in real time because the actual laser optics are used.

- Camera lighting can be tightly controlled inside the laser optics, minimizing external influences.

- Operator is able to monitor the work environment pre-weld for alignment; in real time during welding for laser beam monitoring; and post weld to ensure the quality of the weld.

Disadvantages:

- Resulting image quality is dependent on the design of the optics contained in the image delivery system. In certain situations, an additional light may be required to illuminate the work piece in such a way as to make it visible through the image delivery optics (see drawing above).

- There may be coatings or filters on some of the optical components in the laser beam delivery system that inhibit specific wavelengths of light from travelling up the image delivery optics. This may reduce the visibility of some of the darker background areas around the laser.

- Reflections may appear in the image due to any misalignment in the image delivery system.

- Because the camera’s optical path is the same as that followed by the laser beam delivery, there is a limited field of view which may not allow the camera to see all of the features of interest.

Summary

Weld Cameras can be integrated into laser welding and cutting machines using a coaxial or on-axis approach where the camera uses the same optics as used by the laser. Such an approach provides a physically compact solution but the visible field may be limited by the optics in the beam delivery system.

For more information on how Xiris Weld Cameras can help monitor your weld processes, visit Xiris.com

Sign up to receive our Weld Video of the Month

.png)

.png)