Experienced welders can instantly tell if something is wrong with a welding process just by listening to it. Whether the weld process hums, sizzles or has the occasional pop, experienced welders use audible clues to determine if something is not quite right with the welding process. As part of providing the best training possible, weld educators should consider teaching their students how to “hear” welding. Adding audio training to a welding curriculum is an effective strategy to produce more knowledgeable and intuitive welders. Without audio training, welding educators lose the opportunity to train their students in the use of another sense to detect key welding quality issues.

|

|

By implementing a weld microphone such as the Xiris WeldMic™, into a weld camera setup, instructors can acquire the sounds of a welding process along with captured video. Educators can deliver this content that provides students with the ability to hear audible clues as to what is happening in the welding process and can match that with what they can see in the recorded welding video. So, how can weld educators use audio to improve their weld training?

Here are four ways...

1. Teach students the typical sounds of good and bad welds.

Each welding process makes its own unique noise when it is running: low spatter processes such as oxy-acetylene or non-pulsed TIG are very quiet, much like a candle burning. Pulsed TIG can make a whining sound based on the frequency of the power supply. Stick welding processes can make more of a sizzling sound when active, whereas processes such as short circuit MIG can make loud popping or crackling noises as a result of the metal expulsion and rapid arc flaring and extinguishing. In Submerged Arc Welding, the noise generated can change suddenly when the electrical grounding is interrupted, wire feeding jams or input voltage drops.

In all of these cases, a sudden change in the noise generated by the weld process can indicate to the welding student that something is wrong with the weld process and this can be captured, recorded and played back along with the video.

2. Add voice-over to turn a recorded weld video into a self-guided instruction.

Studying the science of welding and building hands on-skills are the primary focus for many welding programs. Providing voice-over instruction on a recorded weld video offers endless opportunities to deliver essential information as part of the student curriculum. Because students all learn in different ways, voice-over instruction can help adapt the way you deliver information to keep things fresh and engaging. It’s also important to recognize that the way students process information has changed drastically.

Such voice-over instruction can allow for offline, remote learning possibilities to clearly explain what is happening in a particular weld, allowing students to better understand good technique and areas for improvement. It can also provide a great way for lessons to be better integrated into Learning Management Systems, enliven traditional PowerPoint style lectures for better engagement, modernizing traditional welding lessons you have given over and over

3. Use recording audio software to analyze the nature of the welding sounds.

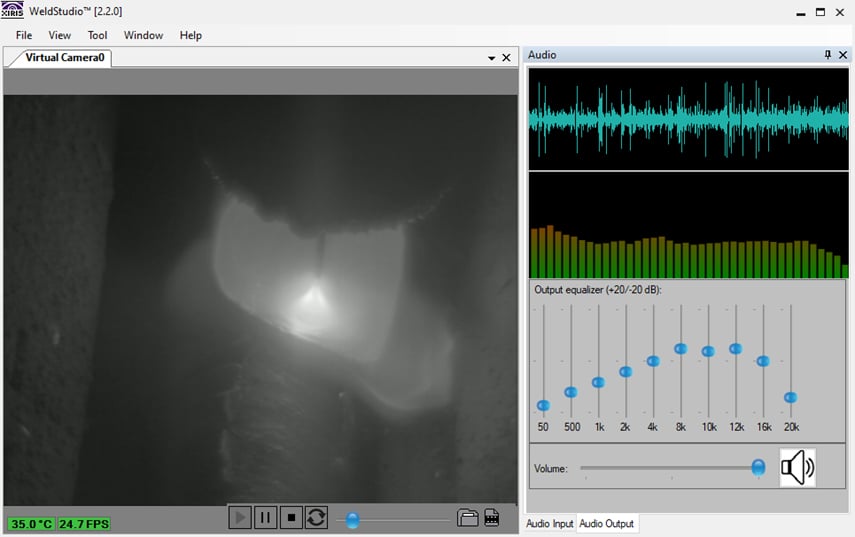

Welding audio can be captured using a welding microphone specifically designed to be able to clearly hear, record and playback the welding sound, along with software that allows the audio signal to be visualized by the user. This can be done with the Xiris WeldMic™ microphone and WeldStudio™ software, providing an audio processing module, a 10 band Equalizer (EQ), microphone controls and visual audio waveform displays that enables monitoring and analysis of the welding sounds live or a recording of the audio information directly to the video files. The EQ can be used on both the live and recorded audio to enhance or minimize key sounds from the weld. The displayed waveform can help to visualize and alert the user to any abnormal process conditions even if not listening live.

Monitoring and analysis of the welding sounds in WeldStudio™

4. Provide better ability to monitor multiple students without having to watch them.

If the weld instructor works in a booth that is remote from where the students are working, they can monitor the students without having to watch over their shoulder. By using speakers or headphones, the weld instructor can listen to the noise of the student’s welding activity and if they hear something wrong, they can help the appropriate student. If multiple microphones have been implemented, their audio output could also be displayed on a computer screen, providing additional information and allowing the instructor to quickly determine whose welding process needs guidance.

Summary

Audio integration with weld cameras can provide new welding students an additional sensory input, sound, to help them monitor and learn how to fine-tune the welding process. A good audio signal will allow the student welder to better understand what to look for in a welding process as well as to learn what audio cues should be monitored for a successful weld.

To learn more about the Xiris WeldMic™ and other Xiris products that are used in an education setting, request a consult with our education expert.

Stay up to date by following us on social media or subscribe to our blog!

Xiris WeldMic™ implemented into a weld camera setup in our welding lab.

Xiris WeldMic™ implemented into a weld camera setup in our welding lab. .png)

.png)