Xiris has been at the forefront of weld monitoring cameras and innovations for more than a decade by continuously innovating and developing new technologies. With our new audio monitoring solution entering the market, our team is already anticipating what we will learn and how we can build on this technology to further enhance our customers’ welding operations.

Product manager, Greg Cooke, says, “We’re just at the beginning of this – there is still a lot of area that we haven’t yet really explored with lots of new opportunities”. With the growth in automation, welding operators are more removed from where the welding is occurring. As a result, they need additional tools, such as audio feedback, to be able to monitor and tune their processes. As audio becomes an important component for assessing welding processes, the next question is: what can we do with the audio information and can we offer additional signal processing and analysis to alert the operator if the process is out of control?

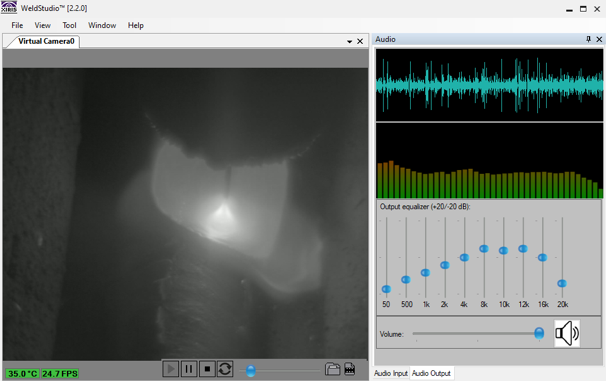

Capturing and displaying the audio signal gives operators additional data to help them understand what is happening during the welding process. The next step is to determine what pitches, volume changes or sound ranges correlate to certain conditions in a weld. By providing some signal processing on the output audio signal, the software could be programmed to alert the operator when the process goes out of control.

The WeldMic™, Xiris’ sensitive weld microphone, can pick up a broad range of audio signals which are outside the range of the normal human ear. Monitoring such frequencies in software can help the operator detect welding features that cannot be heard consistently by all staff. In the future, our software may be able to analyse and provide data about these non-audible sounds, helping operators make any necessary adjustments to their welding processes.

Whatever the future holds, audio monitoring is an important step in helping people monitor welding more reliably. The audio and visual signals together reinforce each other, giving operators critical information to improve their process and product. To learn more about the Xiris WeldMic™, check out our other blogs.

Follow Xiris on social media for regular updates and welding videos!

.png)

.png)