Integrating a Weld Camera to Laser Welding Processes

High powered industrial lasers have been incorporated in a variety of metal fabrication processes, most commonly for welding and cutting applications, where the high power of the laser allows for rapid processing speeds.

As fabricators have adopted industrial lasers throughout their shop floor, it has become painfully obvious to the fabricators that the material being processed by lasers had to be prepared and aligned differently than traditional processes. Because a laser beam is so small, precise fit up and alignment of the material being processed is needed to ensure the laser process is viable.

Careful monitoring of the fit up and alignment is required to ensure a good welding process. Because of the safety issues of being around a laser light, the only practical way to monitor how the material has been prepared and aligned to the laser head was to use a camera that was integrated to the laser beam delivery system.

%20to%20view%20the%20process%20Coaxially%20(with%20the%20Laser).jpg?width=267&height=549&name=Integrate%20a%20weld%20camera%20into%20laser%20welding%20process%20Blog%20weld%20camera%20image%20XVC1000%20camera%20mounted%20on%20a%20Laser%20Head%20(Laser%20Beam%20Delivery%20System)%20to%20view%20the%20process%20Coaxially%20(with%20the%20Laser).jpg)

Xiris XVC-1000 camera mounted on a Laser Head (Laser Beam Delivery System) to view the process Coaxially (with the Laser).

|

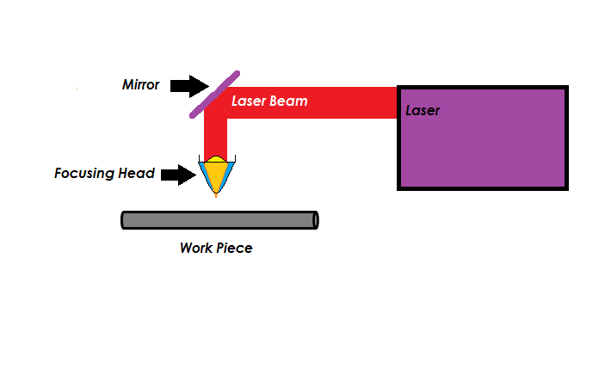

The laser beam delivery system

The laser beam on most cutting and welding systems is delivered to the work piece using a series of optical components such as lenses, filters and mirrors.

Together the assembly is known as the “laser beam delivery system” and can be complex in shape and size to suit the application, as the laser may have to be bent to be as compact and functional as possible.

Most laser beam delivery systems have a camera port integrated into the assembly to allow a camera to view down the same optical path as that travelled by the laser beam.

By adding a camera to the beam delivery system, the operator can monitor the workpiece material to ensure it was properly prepared and aligned prior to powering up the laser.

|

A Simplified Laser Bead Delivery System

The Problem

Once the idea of putting a camera on the laser system has been accepted, there is often frustration with the fact that the cameras most commonly used become useless once the laser is turned on.

Because the laser generates enormous amounts of focused light that partially bounces up to the camera or creates very bright keyholes and weld puddles once it hits the work piece, the resulting image is just too bright for standard cameras to see any detail in the brightest sections of the image.

As a standard camera can see about 48-60 dB of range of brightness, it will simply saturate where the image gets too bright, resulting in a white blob on the screen.

The solution implemented by many fabricators and equipment builders? Turn off the camera when the laser is powered.

A Better Solution

However, a better solution does exist. A high dynamic range weld camera can be used in place of a standard camera to adapt to the laser process.

A good weld camera can see more than 140 dB of range of brightness, or a ratio in excess of 10,000,000:1 of the brightest to darkest pixels in an image.

This allows for detail in the brightest area of the image of a laser weld or cut to be seen without saturation while still seeing detail of the background around the weld, including the weld pool or seam.

By implementing a weld camera to see the laser process, an operator can see what is going on with their laser welding process once the laser power is on, ensuring that the laser beam is functioning correctly: that the beam is focused properly, that the keyhole is of the correct shape (round vs. oval), size and location (relative to the weld seam), and that the weld pool is symmetric on either side of the weld seam and sized correctly.

|

Image from a High Dynamic Range Camera of a 3000 W Laser

|

For more information on how Xiris Weld Cameras can help monitor your weld processes, visit Xiris.com

Sign up to receive our Weld Video of the Month

Stay up to date by following us on social media or subscribe to our blog!

.png)

.png)