Off Axis Mounting of a Weld Camera onto Laser Processes

A High Dynamic Range Weld Camera can provide great benefit to a laser welding or cutting process by being able to see the melt pool and seam while the laser is on. In this blog we explore an additional method of mounting cameras to the laser welding or cutting process – Off Axis mounting of the camera.

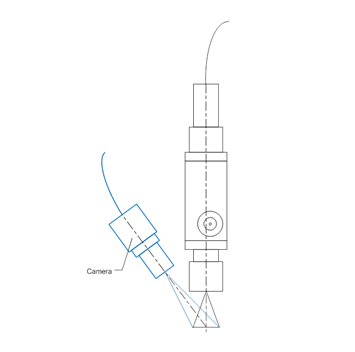

Off Axis mounting of Weld Camera

Off Axis mounting of a weld camera is when the camera is mounted separately from the laser beam delivery head in such a way that it is aimed at the work surface where the laser makes contact. It contains completely separate optics and lighting components with its own mounting mechanism. Because of the flexibility of location, a camera that is mounted off-axis can be placed at any position around the laser head to get the best image. These locations can be categorized as:

1. Forward looking: to see the seam and work environment prior to the weld;

2. Backward looking: to see the weld pool and weld bead after welding; or

3. Sideways looking: to gain an overall perspective of the weld environment.

Off Axis Camera Mounting Relative to Laser Beam Delivery System

In the above image, a simple laser beam delivery system is shown with a camera mounted obliquely to the laser beam optics. This provides the ultimate in mounting flexibility to get the best possible image desired. There are a number of advantages and disadvantages of this type of set up:

Advantages:

- More mounting options as to where and how to place the camera relative to the laser head, with various optical configurations and fields of view possible;

- Extra lighting can be added to see additional background detail that is farther away from laser source and not illuminated by the laser itself.

Disadvantages:

- A separate, sometimes complex mounting system is required that needs to be mechanically coupled to the laser head so that both units travel in tandem without relative movement.

- As most laser beam delivery systems are much larger than the beam spot, the camera has restricted access to be able to view the immediate area around laser spot, making obtaining a good image challenging in some situations.

Summary

Weld Cameras can be integrated into laser welding and cutting machines using an Off Axis mounting technique. Such a technique provides the ultimate in flexibility to acquire different types of images as required by the machine designer, yet not be constrained by the optics in the laser beam delivery system.

For more information on how Xiris Weld Cameras can help monitor your weld processes, visit Xiris.com

Sign up to receive our Weld Video of the Month

.png)

.png)