Metal Additive Manufacturing (MAM) is a fast-growing industry that produces 3D parts, layer by layer, from a powder or wire-based material. While this process offers several benefits to different businesses, many process and quality control challenges can arise due to the complexity of the MAM-produced parts. Over the next few months, we will detail how Short-Wave Infrared (SWIR) thermal imaging can help resolve and prevent some of these challenges and offer precise thermographic measurement capability for high temperatures often found near the melting point of most metals used in MAM.

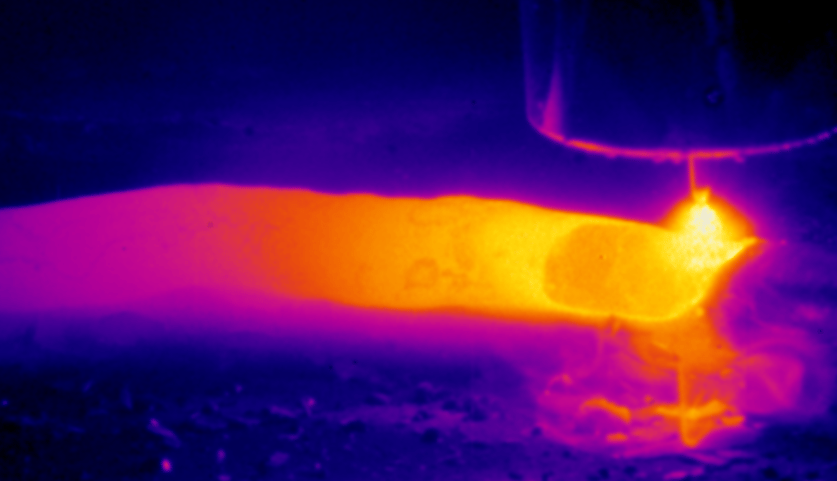

Fig. 1: The Melt Pool and Bead as Seen From a Thermographic Camera

The Problem

The first challenge we are going to be discussing is the harsh environment of the Direct Energy Deposition (DED) process, a form of Metal Additive Manufacturing where the power source travels with the material to be deposited, melting the material as soon as it has been fed. The DED operating environment often has high ambient temperatures, smoke, fumes, and spatter. Sometimes in the DED process, the particulates from the smoke and fumes can limit the view of the process when using visible light imaging systems. In such harsh environments, various measurements become difficult or impossible to perform using visible light imaging.

Our Solution

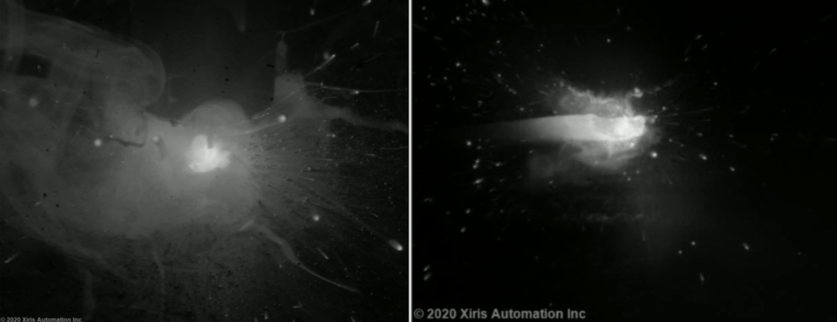

To eliminate this challenge, manufacturers can use a thermal imaging camera such as the Xiris XIR-1800 Thermal Camera, which can see through airborne particulates and glass. Thus, when in use, particulates such as water vapor, smoke and fumes become transparent to the camera. Additionally, metallic greyish hues often associated with the materials used in AM processes that appear almost indistinguishable in the visible spectrum may be easily differentiated using thermal imaging cameras.

Fig. 2: Comparative Images Showing the Same Welding Process in

Visible (Left) and in SWIR Using a XIR-1800 SWIR Camera (Right)

Imaging in the SWIR wavelength is compatible with using standard glass optical lenses and filters which provides a more cost effective, robust imaging solution. With the harsh environments found in a lot of DED processes, this can be especially useful when protecting the optics from spatter and contamination with a simple window. Using standard glass objective lenses provides additional system design functionality to include features that can improve the optical design, such as the inclusion of an adjustable aperture. Implementing a small aperture with a SWIR camera can provide greater depth of field so that objects will appear in focus with clear sharp features across a greater range of distance from the camera. This can reduce image processing steps and offer more reliable measurement results.

Fig. 3. The Xiris XIR-1800 Thermal Imaging Camera

Designed with these issues in mind, the Xiris XIR-1800 Thermal Camera can offer a superior image quality of the DED process which will help to significantly improve the quality of deposition. To learn more, check out the SWIR Thermal Imaging for Metal Additive Manufacturing Whitepaper or request to speak with one of our experts. Stay tuned for the next blog in this series coming out next month.

.png)

.png)