A challenge most fabricators face when using Helical Submerged Arc Welding (HSAW), also known as spiral welding, is ensuring that the welding torch is aligned with the seam during the inner diameter weld. As a granular flux is used in HSAW, it usually covers the welding process, obscuring the operators’ view of the location of the melt pool relative to the seam to be welded.

Operators usually rely on a mirror or a camera mounted on the outside of the pipe to view the “glow spot”, or a hot spot generated from the heat of the torch and visible from the backside of the weld, in this case the outside of the pipe. By aligning the glow spot to the seam location from the outside, operators can ensure they stay on course when welding from the inside of the pipe.

However, when welding thicker material, the glow spot is no longer visible to the human eye as the glow spot is not as bright as in thinner material. As a result, operators are not able to see how their torch is aligned.

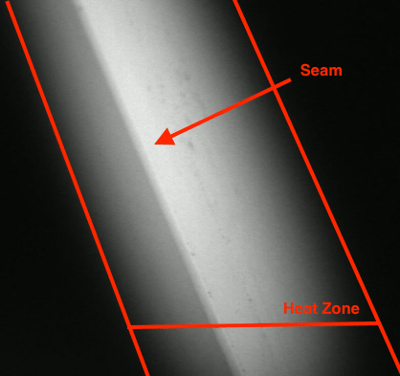

The Heat Zone or “Spot” seen from the backside of the weld, showing the extent of heat and the location of the seam.

A major North American spiral welded pipe manufacturer faced this situation and needed a solution to align the glow spot to the seam. Thermal cameras could see the heat zone of the weld but could not see the seam. Regular, visible light cameras provided a view of the seam, but were not able to show the glow spot or any change in temperature in the pipe material near the weld.

Working with this manufacturer, Xiris developed the XVC-F, a thermally enhanced high dynamic range weld camera that captures both the cooler, physical material structures as well as the thermal response of the hotter welding process all in one image, allowing operators to see the seam-to-glow spot alignment.

The thermally enhanced camera mounted externally to the pipe helps operators maintain the torch position. This result was complemented with a visible light camera on the interior which would help to identify and correct other deviations, such as insufficient flux supply or weld tip damage.

A remote viewing monitor can be configured to display multiple processes, allowing a single operator to monitor the inner and outer sub arc welding processes simultaneously. On the display, the thermally captured heat zone appears white, and the seam of the plate or strip appears as a dark grey groove.

The benefits of this weld camera enhancement are numerous. The thermal camera gives operators a safe, clear display to assess the torch to seam alignment. The ability to view both sides of the welding process results in an increase in productivity and better yield. As well, safety and ergonomics for operators are improved because they no longer have to bend down and look under the pipe to view the mirror.

Since spiral welded pipe is used to transport flammable and non-flammable liquids, the integrity of the pipe is critical. Xiris’ XVC-F sub arc weld camera gives manufacturers a new tool to ensure that they are achieving the highest quality welds by providing alignment to seam monitoring capability. The thermally enhanced weld camera improves productivity and helps to avoid potential faults—leading to greater output for heavy spiral welded pipe manufacturers.

Xiris recently discussed Monitoring the Glow Spot in HSAW Welding in a feature article for the Fall 2020 issue of WELD Magazine. To access the Fall 2020 Issue and other content, you can sign up for a free membership here.

Follow Xiris on social media for regular updates and welding videos!

.png)

.png)