Experienced, professional welders agree that sound is often just as valuable in monitoring welding as being able to see what is going on in the welding process. Issues with wire feed speed, voltage, shielding gas, current and other parameter inputs can all be heard, sometimes more than they can be seen. Giving operators another tool to improve their welding operations and the quality of their products is why Xiris has added audio capture to its industry-leading weld cameras.

Today, we’re sharing 3 ways audio can help your welding process.

1. Multisensory monitoring improves quality. There are many ways to monitor welding operations, such as current, voltage, visual inspection, machine vision sensing, thermal imaging and more. Each method has its own advantages as well as shortcomings. Using multiple monitoring techniques can minimize, or even eliminate these shortcomings.

Audio is another tool to add to your toolbox. Acoustic monitoring may help to overcome some of the challenges of monitoring “dynamic welding characteristics, especially near the arc due to the high temperature, spatter formation, fumes, etc.” 1

2. Audio recording and playback improves real-time monitoring. In order to monitor and immediately control your welding process, you need to know exactly what is happening as it happens. Audio recording and playback allows operators to hear changes as they happen and make the necessary adjustments immediately.

Many factors can affect the generation of welding sounds, such as the volume of the burning arc, the shielding gas flowrate, vibration of the droplet transfer into the welded pool and the noise of the welding apparatus.

3. Audio monitoring can help reduce downtime. Off-line inspections are time-consuming and costly. Finding and correcting welding defects after the welding process is even more costly. Adding audio monitoring to your welding process allows operators to catch mistakes immediately and correct the problem, before wasting time or materials.

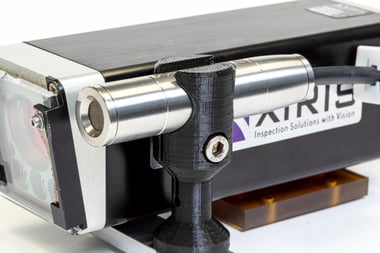

Xiris’ weld cameras, equipped with high dynamic range imaging and now equipped with audio monitoring, can help operators be confident in the quality of their welds and decrease the time spent on post-weld inspection and rework.

For over 10 years, Xiris has focused on helping our customers to detect, identify, address and prevent defects in their welding processes. We know that better images lead to better decisions and better process control. Now, customers can combine those images with audio to further improve their decision-making process.

1 Lv N., Chen S. (2011) Investigation on Acoustic Signals for On-line Monitoring of Welding. In: Tarn TJ., Chen SB., Fang G. (eds) Robotic Welding, Intelligence and Automation. Lecture Notes in Electrical Engineering, vol 88. Springer, Berlin, Heidelberg

Follow Xiris on social media for regular updates and welding videos!

.png)

.png)