With the advent of high dynamic range weld cameras such as the Xiris XVC-1000, images of welding processes can be made with enormous ranges of brightness. As a result, it is now possible to monitor and record good quality video of most welding processes using an HDR camera. With good quality images of the weld pool, arc and seam, the next logical step is to incorporate image processing into the camera system to extract additional information to help operators better control the welding process.

One of the most basic tools for image processing is a LightMeter. The LightMeter tool from Xiris provides statistical information about the pixel values in an area of interest. It can be used as an overall measure of the intensity of a weld process, detect part or feature presence, or be the first step in performing powerful image processing on an area of interest.

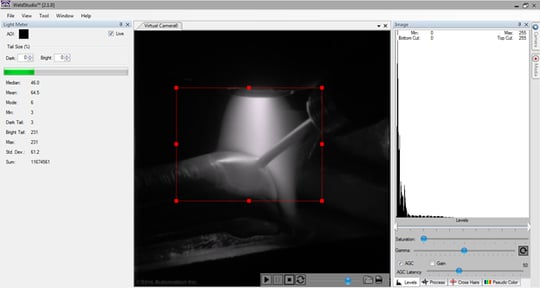

Figure 1 : LightMeter Window

The LightMeter generates a histogram based on the light intensities of the pixels in an area of interest, calculating a number of statistics, including:

Median – the brightness level that separates all the pixels in the area of interest into two equal halves.

Mean - the average brightness of all the pixels in the area of interest

Mode - the pixel brightness level that appears most often in the area of interest.

Minimum - the value of the darkest pixel in the area of interest.

Dark Tail – the pixel value at which a specific percentage of the total number of pixels in an area of interest are found to be darker.

Bright Tail - the pixel value at which a specific percentage of the total number of pixels in an area of interest are found to be brighter.

Maximum – the value of the brightest pixel in the area of interest.

Standard Deviation – the amount of variation or dispersion of brightness levels of all the pixels in an area of interest.

Sum – the addition of all the pixel values in the area of interest.

These measurements can be used as building blocks by users and developers to create automatic inspection algorithms to measure welding features and parameters with the goal of performing a level of process or quality assurance.

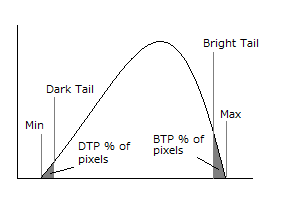

A sample histogram with some of the key features is displayed below:

Figure 2: Sample Histogram

Conclusion:

By incorporating image processing tools such as a LightMeter tool into their weld camera systems, machine builders can measure features of their weld processes in a way that has never before been possible. It is now possible to find and measures levels of light across an entire image, or in a region of interest in an image. This can provide information about features of the weld, such as the weld wire, melt pool or weld seam, that could allow for further monitoring or analysis, or form the foundation for seam tracking or weld pool geometry analysis.

For more information on how Xiris Weld Cameras and the LightMeter image processing tool can enhance the quaity and economy of your welding processes, visit Xiris.com

.png)

.png)