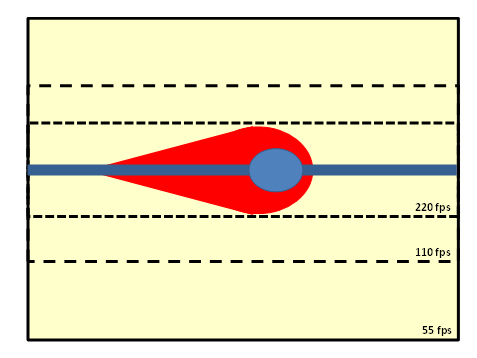

All digital cameras, including the Xiris XVC-1000 Weld Camera, have a digital output signal that is limited by the speed at which data can stream out of the camera. This limits the frame rate of the camera and is a function of the frame size of the camera. For the XVC-1000, the camera can output 55 frames per second at full resolution of 1280 x 1024 pixels. However, it is possible to create a faster frame rate by reducing the size of the image, or Area of Interest (AOI). For example, if the height of the AOI is cut to half the full frame image size, then the frame rate can run twice as fast, e.g. approximately 110 frames per second, or if cut to a quarter its height, the frame rate will be over 200 frames per second. If a very small window is made that could see a small weld process such as a laser spot and a thin weld, the frame rate could run up to 1000 frames per second. This can be very useful in certain situations where features of very short duration need to be monitored.

As an example, many industrial laser welding processes have their laser powered ON for very short durations, usually far less than 2 seconds. This would require a higher speed imaging capability to see exactly what was happening on the weld. As the Area of Interest in a laser process is a long thin rectangular area – typically the weld spot, the seam and a narrow weld pool, reducing the AOI can sometimes be done on a laser process to good effect. The result is a high speed image capture that captures the detail of the laser spot and immediate area around it.

Using the AOI to create a Faster Image

Summary

A digital Weld Camera with Area of Interest capability can be used to image very small, narrow regions of interest at high speeds by reducing the Area of Interest of the camera. As such, Weld Cameras can be used as a valuable tool for set up and alignment of high speed laser processes.

For more information on how Xiris Weld Cameras can help monitor your weld processes, visit Xiris.com

Sign up to receive our Weld Video of the Month

.png)

.png)