One-step Helical (or Spiral) Submerged Arc Welding (HSAW) processes do not use GMAW/GTAW systems to tack the material into pipe form like two- step processes, but rather perform full inner welds using a sub arc welder during the initial forming stage.

This one-step process is advantageous in that it requires less equipment, and therefore less shop floor space, but it results in significantly lower processing speeds compared to the two-step process.

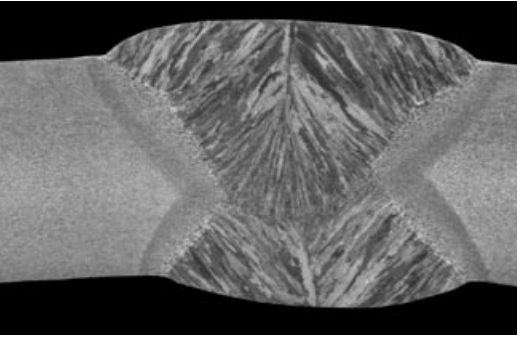

Both one- and two-step HSAW processes use dual-system submerged arc welding with flux recovery systems to perform the complete welds, with a preliminary weld on the inner diameter and a secondary weld on the outer diameter. Using two HSAW systems in parallel allows the weld penetration depths to meet, providing a strong weld in wall thicknesses as large as 1”.

Cross section of Dual Sub Arc Welded Seam [1]

Cross section of Dual Sub Arc Welded Seam [1]

The quality of these welds is paramount to the success of the pipe. With applications in the transportation of oil, natural gas, water, and other flammable and nonflammable liquids, a small defect in the weld seam affects not only the density of the weld—causing higher risk of leaks—but also becomes a major point of corrosion-induced wear. Porosity, thermal cracking, undercut, and insufficient penetration are all critical defects caused by relatively common circumstances during the submerged arc welding process.

Detecting Defects Sooner With HDR Weld Cameras

Various standards organizations such as the American Society of Testing and Materials or the American Water Works Association prescribe hydrostatic testing to 2800 psi / 193 bar, as well as ultrasonic or radiography testing, to ensure the quality of the weld seam for its service life. But these tests determine the quality of the seam in a retroactive way, after the defects have already propagated throughout the tube.

The Xiris Weld Camera for Sub Arc applications, the XVC-S, is an affordable turnkey solution for monitoring the sub arc welding process. The XVC-S features an out-of-the box solution with integrated lighting, graphical-overlay-producing crosshairs, and a rugged housing suitable for the welding environment.

With on-screen monitoring tools, operators can easily identify and correct any deviations from standard operating procedures, including insufficient flux supply, misalignment of the torch or seam, and damage to the weld tip. The remote viewing monitor can display multiple processes, allowing a single operator to monitor the quality of the inner and outer sub arc welding processes simultaneously.

Operator remotely monitoring a sub arc welding process

Operator remotely monitoring a sub arc welding process

The small size of the XVC-S camera allows it to be easily integrated into an existing sub arc welding mount and the high-voltage and high-temperature resistant design, combined with the built-in solid-state lighting, allows high-quality images to be produced even in the harshest environments. By ensuring the quality of the weld during the sub arc welding process itself, defects can be caught sooner and corrected before the quality of the entire pipe length is compromised—saving time, money, and resources to provide an overall more-efficient process.

[1] RIBEIRO, Anderson Clayton Nascimento; HENEIN, Hani; IVEY, Douglas G. and BRANDI, Sergio Duarte. Evaluation of AH36 microalloyed steel welded joint by submerged arc welding process with one and two wires. Mat. Res. [online]. 2016, vol.19, n.1 [cited 2017-06-22], pp.143-152.

.png)

.png)