For certain types of pipe cladding operations, fabricators have to preheat the parent metal in order to achieve better cohesion between the cladding and the base pipe material.

With inside-diameter (ID) cladding, this heating means that the inside of the pipe becomes too hot—often well over 500° F (260°C)—for direct monitoring of the cladding application by the operator. The space inside the pipe is also often limited, with pipes as small as 4 inches commonly requiring in ID cladding.

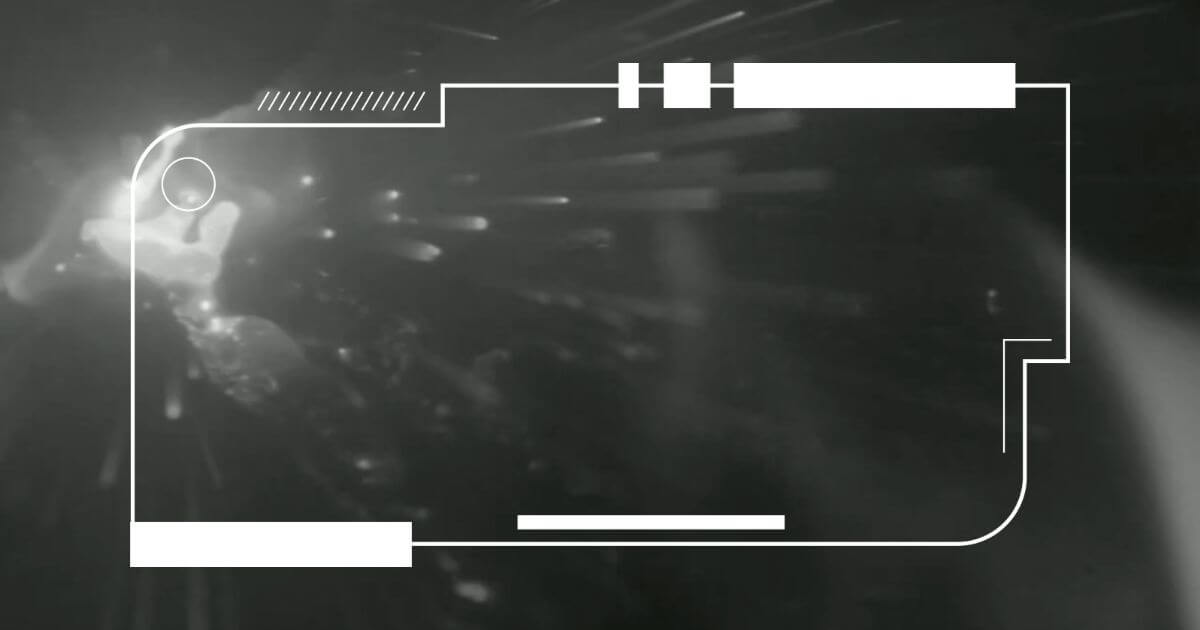

A Weld Camera is the ideal solution for monitoring ID cladding because it can fit in a narrow pipe and provide an image that can be viewed remotely by the operator. If the Weld Camera is equipped with High Dynamic Range imaging technology —an essential feature for advanced Weld Cameras—it can provide operators with real-time, high-quality images of the weld process characteristics.

A Weld Camera is the ideal solution for monitoring ID cladding because it can fit in a narrow pipe and provide an image that can be viewed remotely by the operator. If the Weld Camera is equipped with High Dynamic Range imaging technology —an essential feature for advanced Weld Cameras—it can provide operators with real-time, high-quality images of the weld process characteristics.

But the extreme heat present in the pipe also presents a challenge for Weld Cameras. To withstand the high temperatures often found in ID cladding, Weld Cameras need special design considerations to prevent overheating.

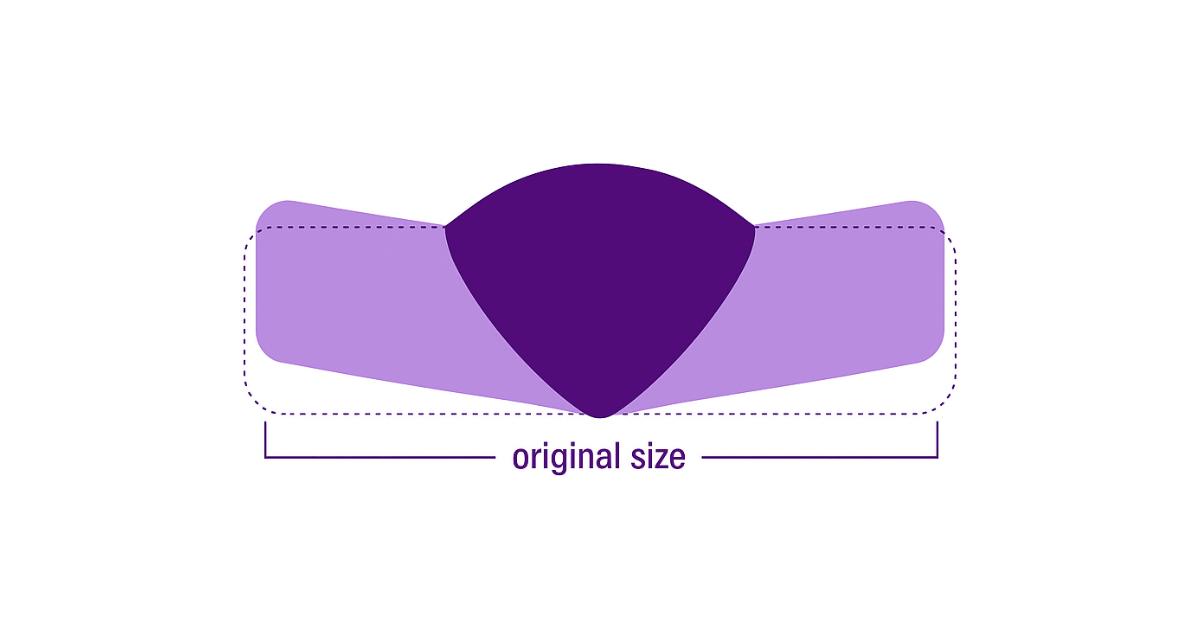

To meet this challenge, Xiris has engineered a cooling kit that consists of a cool-air generator and a thermal blanket enclosing the camera and cables. We tested the Xiris XVC-O Weld Camera inside this kit, exposed to over 300° C (approximately 600° F) for the better part of a day—and the XVC-O kept its temperature at about 30° C (86° F), well within safe operating range of the camera.

This cooling kit enables fabricators to use the XVC-O to view welding processes such as high-temperature ID cladding to make necessary in-process adjustments, when it would otherwise be impossible to sufficiently monitor the weld quality. In ID cladding, the cooling kit is key to unlocking the benefits of the XVC-O and its High Dynamic Range imaging technology.

Conclusion

Weld Cameras with High Dynamic Range imaging can provide operators with a clear, high-detail view of weld features so they can use their experience and judgment to make cost-saving, quality-enhancing adjustments. But in ID pipe cladding or any other welding application in a high-temperature environment (e.g., oil and gas operations, nuclear power plants), Weld Cameras need a special cooling solution to keep the camera within safe operating temperature.

Xiris has developed such a solution for its XVC-O Weld Camera, allowing it to be installed in a diverse range of welding applications.