The problem: A large fabricator in Mexico employed welding operators high atop their welding manipulators to monitor the process of Submerged Arc Welding (SAW) of large steel pressure vessels. Each time an operator needed to come down from their monitoring perch (eg: break time, equipment malfunction, end of shift, etc.), approximately 15 minutes of production time was lost. Not only did the equipment need to be stopped and the path down secured, auxiliary personnel at the base station were needed to provide safety backup to move the manipulator out of the way and lower the boom for the welding operator to climb off the machine at ground level. Another 15 minutes were lost while the path was re-secured, the operator returned to the monitoring perch and the manipulator was realigned in order to resume production. Each of these 30 minute cycles represented a significant loss of productivity for the company.

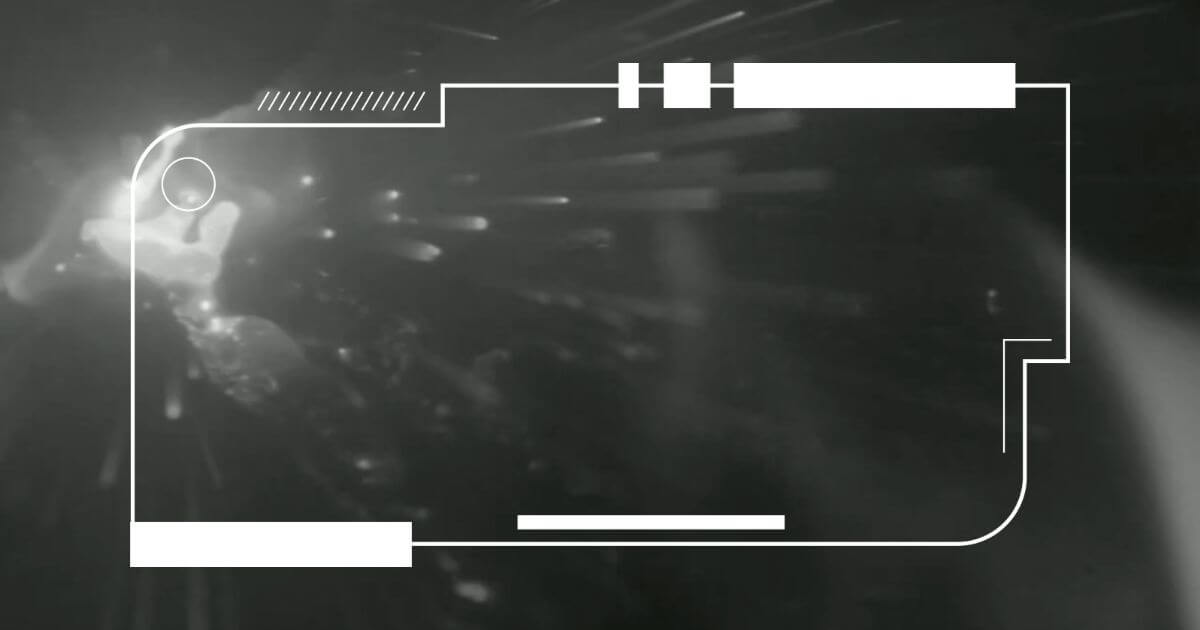

The Solution: The fabricator needed a solution to improve their productivity. Recognizing that a 30 minute delay, 2-3 times per shift was uneconomical and, in the long run, unsustainable, the fabricator was able to rationalize the purchase of a Xiris XVC-S Sub Arc Camera. The improvement in productivity alone was sufficient to justify the acquisition. Once a sub arc weld camera was installed at the weld head and the machine controls, along with a new monitoring screen, were moved to the machine's base platform at ground level, operators were no longer required to be stationed high above the shop floor.

The Result: Now, when an operator needs to leave the machine, it is a simple matter of putting the machine on pause and walking away. Since the manipulator remains in place and safety backup is no longer required, the time and productivity lost to a production interruption has been dramatically reduced to just a few minutes.

An additional benefit of this set-up is that operators, monitoring the weld process remotely, at the ground level control station, are far less fatigued during their shift. They no longer have to climb up and down from their workstations nor must they lean out over the weld head to monitor the proceedings.

For more information on how Xiris Weld Cameras can help monitor your weld processes, visit Xiris.com

Sign up to receive our Weld Video of the Month