In some demanding Pipe welding applications, special materials need to be used in order for the pipe to be able to carry highly corrosive or abrasive media. However, because it’s prohibitively expensive to make a pipe entirely out of stainless steel or some other exotic alloys, fabricators often use a pipe made of a less-expensive material, such as carbon steel, and apply a layer of highly corrosion-resistant or wear-resistant alloy using a Pipe Cladding welding process.

MIG Pipe Cladding

The result is the best combination—the excellent strength and ductility of carbon steel as the base foundation of the pipe, with a clad layer of exotic alloys on the inside, as well as sometimes on the outside, of the pipe for resistance to corrosion and wear.

Nonetheless, the Pipe Cladding process takes place under such difficult environmental conditions that it’s almost impossible to place an operator for direct monitoring of the weld process.

How to Monitor Inner Cladding Processes in Small Pipe?

The diameter of most pipes that are clad is so small that it’s very difficult, if not impossible, for a human being to fit inside. Even for those pipes large enough to fit a person, very few operators are willing to work in such tight, closed areas for anything longer than a brief encounter.

Adding to the difficulty in certain Pressure Vessel or Pipe Cladding applications, the parent material is preheated to ensure a good bonding of the cladding material. In such cases, the parent material could be heated up to temperatures as high as () or more prior to the cladding process taking places—so hot that special cooling procedures are required for the Weld Camera.

Dealing with the Tight Space

Many fabricators are turning to automatic or semi-automatic welding processes such as a column and boom operation, which has a weld head and Weld Camera mounted to the end of the boom. The boom can move through a pipe and lay down a layer of weldment as the pipe is rotated.

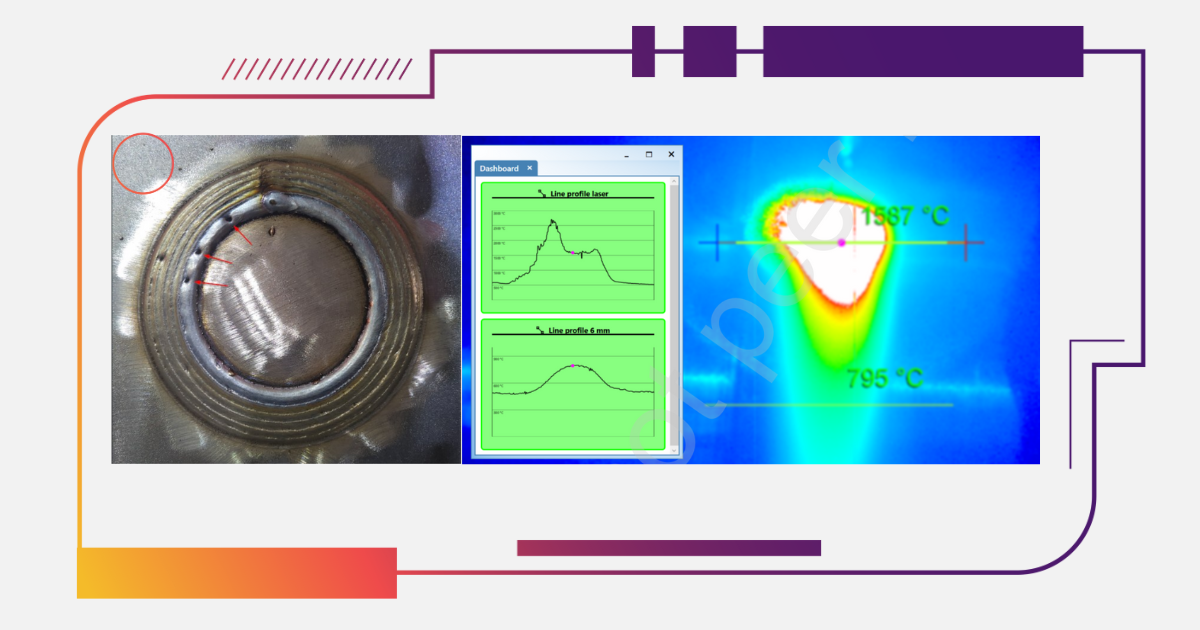

However, some pipe is so narrow that special consideration must be given to how to position the camera. For small-diameter pipe, a Weld Camera can be installed that’s equipped with a mirror to allow the camera to see the inside surface of the pipe and the resulting weldment. The mirror can be mounted at an angle to see what the weld head is working on and the resulting surface.

Dealing with the Heat

For the very-high-temperature welding processes that get used in Pipe Cladding, specially designed cooling can be effectively employed on the Weld Camera to keep it in a safe operating temperature range. Special thermal insulating layers can be applied around the camera, and cooled air can be circulated between the thermal layer and the camera. This provides a thermal boundary between the camera and the ambient environment, allowing the camera to withstand extremely high temperatures.

Xiris has developed a high-temperature cooling kit that has been proven in the field to indefinitely keep the Weld Camera at an ideal operating temperature of under () while the ambient temperature is much higher.

Conclusion

Pipe Cladding is a challenging automated welding process to monitor correctly with a Weld Camera. Both size restrictions and high temperatures make it impractical for operators to monitor the weld process directly, so a remote monitoring solution must be used.

With proper design features and imaging capabilities, a Weld Camera can fit small-diameter pipe and see the welding process while dealing with high temperature, enabling an operator to remotely monitor the cladding process in real time.

.png)