High-speed mode of XIR-1800

In previous blogs, we talked in detail about the thermal measuring capabilities of the XIR-1800 thermal camera.

In this blog we would like to discuss another feature that is often beneficial for research: higher speed imaging.

In welding or additive manufacturing (AM) research, it is often necessary to look deeper into the welding process to get an insight that cannot be provided by a naked eye.

Droplet transfer and motion of the weld pool are more rapid than what can be detected by a human eye.

Standard weld cameras also might not be able to provide a high enough frame rate for detecting some phenomena. To monitor droplet detachment, spatter formation, transfer of the molten metal into the weld pool, etc., higher speed imaging is needed.

There are many high-speed cameras on the market today that reach frame rates of tens, or even hundreds, of thousand frames per second.

Depending on the application and user requirements, it can be a visible or infrared camera that uses the arc light or an external pulsed laser for illumination.

However, such capabilities make often make for complicated and expensive systems.

There are some areas of research where tens of thousands of frames per second are not necessary, where only a few hundred frames per second would be suitable.

In such cases, spending extra for such excessive capabilities that may not ever be used may become hard to justify when purchasing the system.

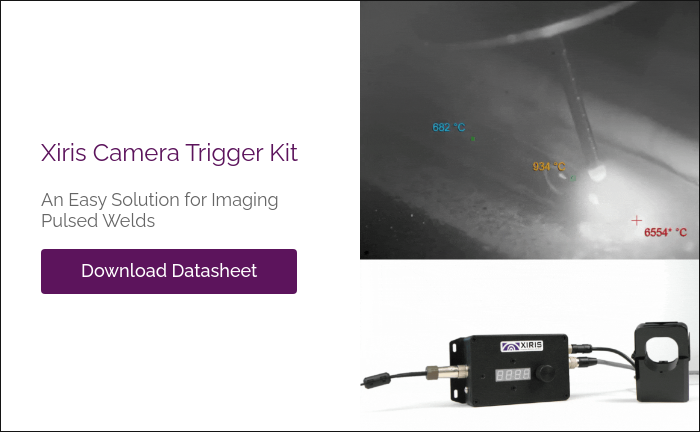

As discussed in previous blogs, XIR-1800 is a unique thermal camera that can perform temperature measurements in welding without getting saturated by the brightness and heat of the arc.

However, this camera also has a special high-speed capability.

With its regular frame rate of 180 frames per second in full frame resolution, the camera can achieve up to 700 fps with a short exposure time and reduced resolution.

Frame rates of 500-700 fps are often sufficient to monitor welding physics phenomena, such as powder flow in Laser DED or metal transfer in GMAW.

For example, short circuit GMAW processes are reported in literature to have droplet detachment frequency of the order of 75-200 Hz.

With a frame rate of 500-700 fps, each cycle will be recorded with a decent level of detail with equipment that costs a fraction of the price of a high-speed camera.

You may find this article interesting: The Magic of Aluminum Welding Captured in Detail

.png)

.png)