A Weld Camera can be placed at various locations around the weld head to see different features that are present—upstream or downstream of the weld head, or from the side.

The benefits of each view depend on:

- The specific conditions desired for display.

- The field of view chosen.

- The mounting angle of the camera relative to the work pieces.

- Camera placement that can enhance specific features of an open arc for viewing.

Each orientation of a Weld Camera allows certain features to be seen.

Before the Weld Head

By placing the Weld Camera before the weld head (i.e., upstream), the operator can monitor the mechanical features of the seam and wire, the tracking of the seam to the weld head, and related features. Specifically, this would include a good view of:

- The weld seam (to confirm the quality of the fit-up of the seam edges to be welded).

- The weld head position relative to the seam (to ensure that the weld head and seam are in alignment).

- The feeder wire or wire stick-out (to ensure that the feeder wire is being fed correctly and not missing or incorrectly positioned).

- The penetration of the welding wire and its arc in the root of the seam.

- The shielding gas around the arc (to determine if the gas quantity and chemistry is correct).

Placing the Weld Camera before the weld head is especially useful for semi-automated welding systems, such as gantry systems, where the operator monitors the weld and its position relative to the seam, then controls the welding manipulator with a remote joystick.

After the Weld Head

By placing the Weld Camera after the weld head (i.e., downstream), the operator gains a real-time post-weld visual tool to monitor the weld pool condition as it solidifies. Specifically, this would include a good view of:

- The weld puddle (to confirm correct form).

- The feeder wire when wire feed is made from behind the weld tip, such as on TIG (to ensure that wire is being fed correctly, in the right position, and melting properly).

- The molten weld pool (to detect the presence of bubbles that are good indicators of potential porosity in the weld).

- On TIG and Plasma Tube and Pipe mills, the weld seam position that can be seen through the arc to upstream of the arc.

- The wetting and cut of parent material (to ensure proper form).

- The weld puddle solidification (to ensure no cracking, porosity, or surface contaminants).

- Potential undercut occurring in the weld as a result of incorrect alignment of weld head to seam or incorrect pressure on the parent material.

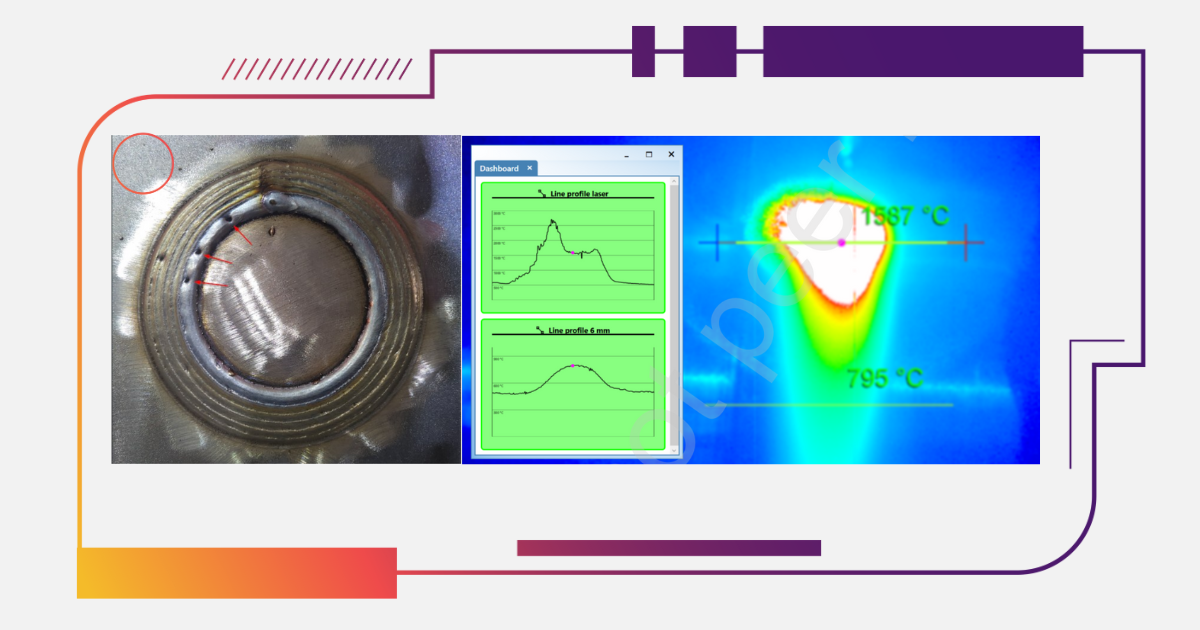

From the Side

By placing the Weld Camera to look at the weld head from the side, a unique view of the weld head and its parameters can be obtained. Special benefits of a side view include:

- Better visibility for monitoring some items (e.g., how feeder wire gets positioned, fed, and melted and flows into the weld pool).

- Easier camera mounting when space is at a premium before or after the weld head.

- Easier adjusting, positioning, and focusing of the Weld Camera.

- The best view for monitoring interaction in the weld pool when two or more weld torches are used in tandem (e.g., for thick walled pipe fabrication).

- Usefulness in Cladding/Overlay applications (e.g., TIG cladding inside a small diameter pipe or vessel) where the wire position relative to the weld puddle is important to monitor while simultaneously viewing the wetting and fusion of the leading edge of the weld.

Conclusion

Your particular welding needs will determine whether you should place your Weld Camera in front, behind, or to the side of the weld held in order to obtain the images of the weld that will provide the unique information necessary to aid in the monitoring of your process.

.png)