What do lunar dust, laser heat, and metal innovation have in common? Each pushed the boundaries of what’s possible in manufacturing this year, and each relied on the Xiris XIR-1800 SWIR thermal camera to capture it.

Since its release, the Xiris XIR-1800 SWIR thermal camera has become a sought-after tool for welding and metal additive manufacturing (AM) researchers. Its ability to measure temperature and cooling rates in-situ during AM, welding, and cladding has made it an irreplaceable tool in labs across the globe.

Below, we spotlight several notable publications from this year that leveraged the XIR-1800 to advance materials and manufacturing science.

Lunar Regolith for Additive Manufacturing

Ana Luisa C. de Lucena et al., Technical University of Denmark

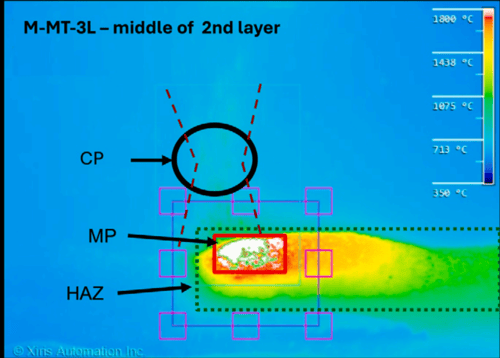

In a previous blog, we highlighted the work “Laser-based directed energy deposition with mullite: a necessary step for lunar regolith printing.” [1] This study explored the feasibility of using lunar regolith—a naturally occurring ceramic material on the Moon’s surface—for in-situ additive manufacturing on the lunar surface. The researchers demonstrated that regolith is a viable feedstock for Laser-based DED processes.The XIR-1800 played a crucial role by accurately capturing melt-pool temperatures. The team emphasized that the SWIR technology of Xiris’ thermal camera provides higher temperature-measurement accuracy than traditional MWIR and LWIR systems—an essential advantage for extraterrestrial manufacturing research.

Figure 1. Laser DED of lunar regolith as seen by the XIR-1800 thermal camera [1]. |

Implementing WAAM in Welding Automation

Mikael Fagerström, Lappeenranta–Lahti University of Technology

In his Master’s thesis, “Implementing WAAM into Welding Automation and Comparing It with Traditional Manufacturing Methods,” [2] Mikael Fagerström investigated how Wire-Arc Additive Manufacturing (WAAM) can be integrated into existing production workflows for bearing housings.

An XIR-1800 thermal camera was used to detect weld defects such as lack of fusion, providing critical insight into process reliability.

Congratulations to Mikael on successfully completing his Master’s degree!

Figure 2. WAAM of bearing housing with weld defects [2]. |

Creep Performance of Haynes 282 Alloy in GMA-DED

Sophia Hill, Jamie McIntyre, and Jonah Klemm-Toole, Colorado School of Mines

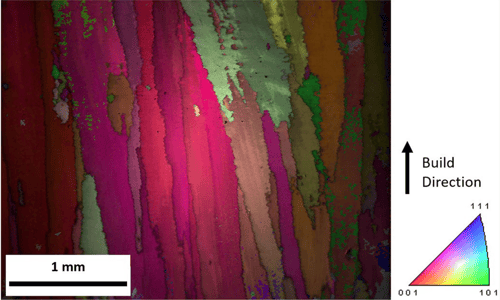

In their study, “Microstructure and Creep Performance of Direct Single-Step Aged Gas Metal Arc Directed Energy Deposition Processed Haynes 282,” [3] the authors built components for high-temperature power-generation applications using GMA-DED with Haynes 282, a nickel-based alloy known for thermal stability.

The XIR-1800 was employed to monitor interpass temperatures around 650 °C. The resulting components showed creep performance intermediate between wrought and cast samples—an encouraging outcome for the use of DED in critical-temperature applications.

In another publication [4], Hill and Klemm-Toole further developed an analytical model to predict creep-rupture times for wrought, cast, and DED-fabricated Haynes 282 components.

Figure 3. —EBSD IPF + IQ map of direct-aged GMA-DED Haynes 282 in the middle of the build [3]. |

Laser-Modified Wire Arc Cladding

Hana Šebestová et al., Institute of Scientific Instruments of the CAS, Czech Republic

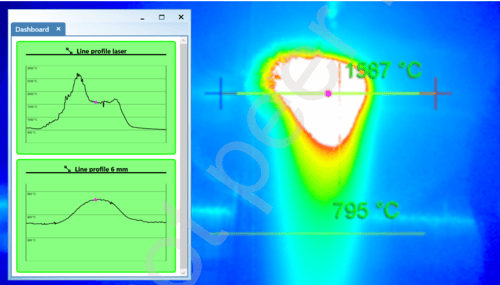

This compelling work, “Laser-modified wire arc cladding,” [5] examined the introduction of supplementary laser heating during wire-arc cladding of Stellite 6. Traditional wire-arc cladding of this alloy is prone to cracking; however, the addition of in-situ laser heating reduced cooling rates by up to 40%. This led to improved bead quality, fewer voids, and higher deposition rates while maintaining structural integrity.

Cooling rates across temperature intervals of 1200–800 °C, 1000–800 °C, and 800–500 °C were measured using the XIR-1800 SWIR camera.

Find more about our novel Cooling Time Tool for real-time measurements in Cooling Time Whitepaper

Figure 4. The temperature field induced by the laser and the temperature profiles on the substrate surface from [5]. |

Automated Monitoring in WAAM

Prashant Kumar Chaurasia et al., BAM, Germany

The study “Automated in-situ monitoring and analysis of process signatures and build profiles during wire arc directed energy deposition” [6] focused on improving dimensional consistency in WAAM-fabricated parts. The team investigated optimal step-over ratios between adjacent weld passes.

Using both the XVC-1000 weld camera and the XIR-1800 thermal camera, they synchronously captured surface profiles, melt-pool images, and top-surface temperature distributions via a centralized real-time monitoring system.

The collected data contributed to the Open Source Weld Data format [7] developed and promoted by the team—an exciting step toward standardized, shareable weld-process data.

Figure 5. Monitoring framework used in [6]. |

Steel-on-Tungsten Deposition with Intermediate Layers

Md Abdul Karim et al., Tennessee Technological University, USA

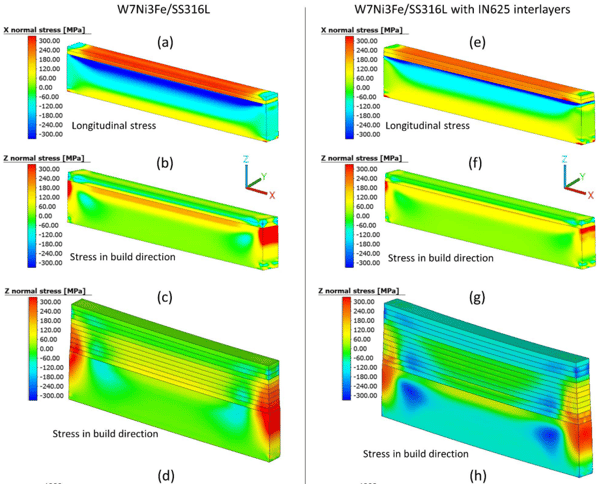

In “Wire-arc directed energy deposition of steel onto tungsten substrate: fabricability and mechanical performance of synergistic structures,” [8] the authors explored depositing SS316L stainless steel directly onto a tungsten heavy alloy substrate (W7Ni3Fe). While direct deposition proved unsuccessful, the introduction of an intermediate Inconel IN625 layer enabled successful bonding and acceptable mechanical performance—an important insight for hybrid metal structures.

Figure 6. Residual stress distributions and thermal cycles in W7Ni3Fe/SS316L structures with and without IN625 interlayers from [8]. |

References

[1] de Lucena, Ana Luisa C., Navid Ranjbar, Saeed Khademzadeh, and Mohamad Bayat. "Laser-based directed energy deposition with mullite: a necessary step for lunar regolith printing." Materials & Design (2025): 114605.

[2] Fagerström, Mikael. "Implementing WAAM into welding automation and comparing it with traditional manufacturing methods." (2025).

[3] Hill, Sophia, Jamie McIntyre, and Jonah Klemm-Toole. "Microstructure and Creep Performance of Direct Single-Step Aged Gas Metal Arc Directed Energy Deposition Processed Haynes 282." Metallurgical and Materials Transactions A (2025): 1-16.

[4] Hill, Sophia, and Jonah Klemm-Toole. "An Analytical Creep Rupture Time Model for Wrought, Cast, and Gas Metal Arc Directed Energy Deposition Haynes 282." In Pressure Vessels and Piping Conference, vol. 89091, p. V05BT06A019. American Society of Mechanical Engineers, 2025.

[5] Šebestová, Hana, Jan Novotný, Jan Štěpán, Ondřej Ambrož, Zdeněk Joska, Jan Gross, and Libor Mrňa. "Laser-modified wire arc cladding." Available at SSRN 5534586.

[6] Chaurasia, Prashant Kumar, Çağtay Fabry, Andreas Pittner, Amitava De, and Michael Rethmeier. "Automated in situ monitoring and analysis of process signatures and build profiles during wire arc directed energy deposition." Progress in Additive Manufacturing (2025): 1-20.

[7] Fabry, Cagtay, Andreas Pittner, Volker Hirthammer, and Michael Rethmeier. "Recommendations for an Open Science approach to welding process research data." Welding in the World 65, no. 9 (2021): 1661-1669.

[8] Karim, Md Abdul, Saiful Islam, Gazi Tanvir, Sainand Jadhav, Young-Min Kim, Yongho Jeon, and Duck Bong Kim. "Wire-arc directed energy deposition of steel onto tungsten substrate: fabricability and mechanical performance of synergistic structures." Virtual and Physical Prototyping 20, no. 1 (2025): e2443578.

.png)

.png)