The benefits of SWIR monitoring for welding and Metal Additive Manufacturing (MAM) processes have been discussed in detail in previous blogs. From the ability to see through fumes and smokes in a harsh environment to higher sensitivity of wrongly adjusted emissivity, SWIR has proven to be potentially the best spectral sub-band for monitoring most Metal AM and welding processes. Among the many other unique features of SWIR imaging, there is one more – a resulting bright, clear view of the weld pool.

The weld pool is by far the most important feature to monitor in a welding process. Particularly, the weld pool shape, size, and location are of most significance, as they define the resultant quality of the weld joint. In Metal AM processes, melt pool monitoring is also important as instability of the melt pool size and shape is a direct indication of the deposition process stability. For example, an oversized melt pool is evidence of overheating of the deposited material and can indicate potential problems with future material layers.

We often talk about the human-like vision provided by SWIR thermal imaging and the reason SWIR has this unique feature is because it is a part of the electromagnetic spectrum that is closer to visible light than the MWIR and LWIR spectrum that are used in traditional thermal cameras. The result is that a SWIR image appears just like a regular visible monochrome image. One thing is different, however: the weld pool and weld bead are much more distinguishable in a SWIR image. Why? Here’s a bit of a physics explanation:

The above image shows the SWIR Band Chart (Source: Wikimedia Commons user Sch, adapted by Sun.org)

The above image shows the SWIR Band Chart (Source: Wikimedia Commons user Sch, adapted by Sun.org)

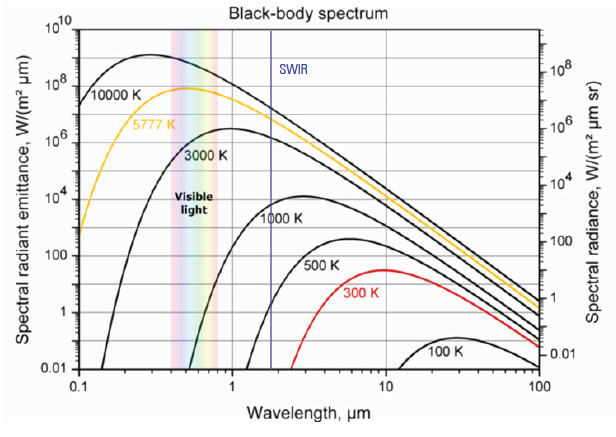

Objects at every temperature emit light in the whole electromagnetic spectrum, from ultraviolet to infrared. However, depending on the object temperature, there is more light emitted in certain parts of the spectrum than others. For example, the peak of sunlight is in the visible range, with less light emitted in the ultraviolet and infrared ranges. The human eye has evolved over time to work best near this peak, which we now call ‘visible light’. While the sun, whose surface is at nearly 6000K, emits peak light in the visible light range, most metals such as steel, emit peak light in the SWIR range when they are close to their melting temperatures.

Therefore, SWIR cameras such as the Xiris XIR-1800 Thermal Camera, are particularly more sensitive to the wavelengths of the naturally emitted light coming from hot metal such as the weld pool, than in any other wavelengths. At the same time, there is less light emitted from the weld arc in the SWIR range than in the visible light range, rendering it less visible.

Short SWIR Video Showing the Melt Pool and Cooling Weld Bead

Short SWIR Video Showing the Melt Pool and Cooling Weld Bead

The result of all this is that SWIR imaging can generate excellent, high contrast images of the weld pool, providing clear details of its size, shape and surface texture, regardless of the presence or absence of the weld arc or external light sources.

To learn more about other thermal weld monitoring applications, visit our SWIR Thermal Imaging Guide. For more information on the XIR-1800 Thermal Camera, visit info.xiris.com/xir-1800 or contact one of our product experts.

Stay up to date by following us on social media or subscribe to our blog!

.png)

.png)