Recent advancements in machine vision technology have made a new type of inspection able to see defects related to the forming and welding area of a tube or pipe. The result is improved quality assurance and process control on the production line. The new type of inspection device is a laser-based triangulation system that measures the outside contour of a tube or pipe in the vicinity of its weld.

Typically NDT systems are placed at the end of a production as a final check. However, the laser inspection system can be placed directly after the weld box. This system can let operators know what is changing in their welding process, allowing them to perform corrective action before significant scrap occurs. This capacity is especially helpful for one of the most common defects found across all types of Tube manufacturing: Tube Bead Height Defects.

The Bead Height Defect (Raised or Sunken Welds)

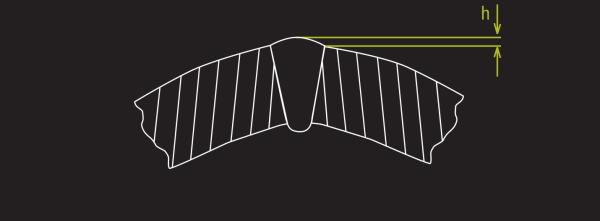

The material in the bead area may rise on top of the tube parent material surface (known as a “raised weld”) or drop below it (known as a “sunken weld”), depending on the compression force applied, the metallurgy of the material and the welding process parameters.

A sunken weld defect is a visibly significant and quality critical defect that could create weakness in the tube along the bead. While a raised weld defect may not be considered as an important a defect (as it can be ground off later), it can indicate quality problems in the setup of the welding process.

The bead measurement is defined as the largest absolute value of a raised or sunken weld. Calculating the bead metric in this way helps to determine the height of the tube material that needs to be ground off to smooth the profile (and restore the cylindrical shape, as required). In cases where there exists a mismatch defect at the same time, the bead metric will include the mismatch measurement and will report the total loss of the material thickness after grinding.

The Bead Height Defect, where “h” = the height of the defect.

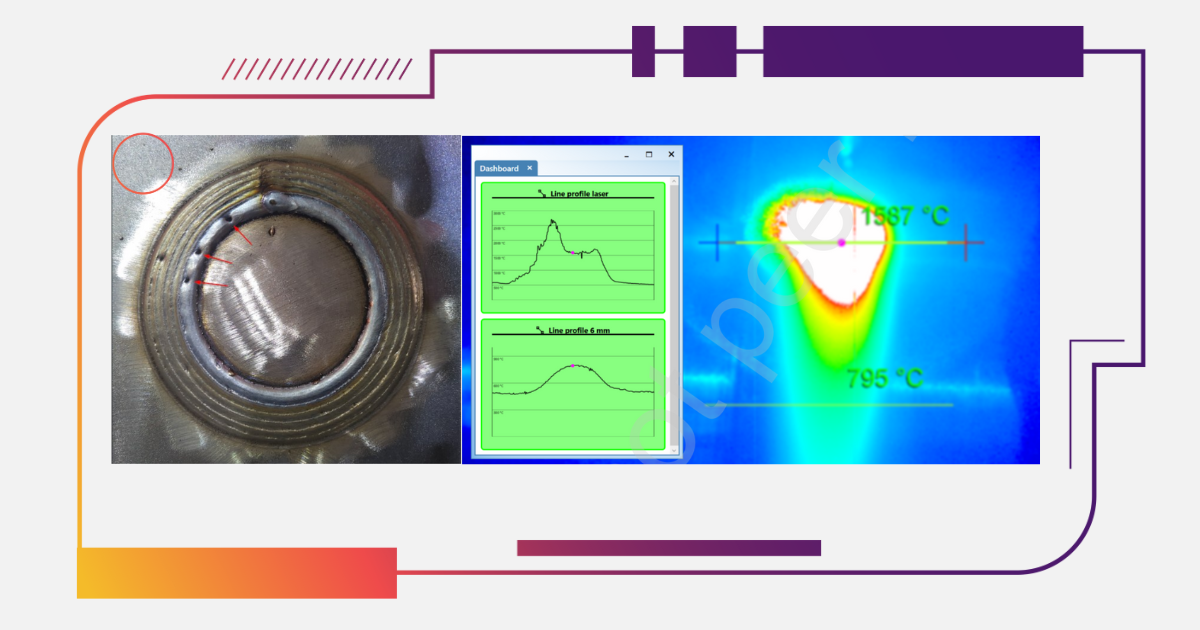

How the WI2000p System Measures the Bead Height Defects

Xiris Automation Inc. has developed a non-destructive inspection system called the WI2000p Weld Inspection System. The WI2000p includes a laser line and a camera whose optical axis is offset to the axis of the laser line by an “offset angle”. The WI2000p creates a visible cross-section of the tube by projecting the laser line on to the tube and capturing an image of the line using the camera. The resulting image shows a profile of the tube surface as if it were cut in cross section. If a tube is ideally round, the laser image will represent a section of an ellipse and any anomaly such as Bead Height defects can be mathematically detected.

The WI2000p bases all of its measurements on the differences between the actual laser profile line seen by the camera, and the ideal mathematical profile based on the tube parameters. By knowing the position of the actual laser profile, the ideal profile, and the size of the pixels in the image, the WI2000p can detect Bead Height profile defects that often escape detection by other quality tools such as Eddy Current testing, or Ultrasonic Testing techniques

Conclusion

A new technique for detecting Bead Height defects on welded Tube and Pipe has been developed by Xiris and is known as the WI2000p weld inspection system. The WI2000p system is a laser based inspection system that is capable of detecting Bead Height defects immediately after welding to alert the operator of a defect in time to minimize rejects. The result is improved quality, fewer field defects and a more reliable method for the operator to optimize the welding process.

.png)