Xiris recently received a call from a prospective client asking about our XVC-S Submerged Arc View camera and how it worked. They had two main questions: Can two welding cameras be monitored simultaneously? And can their images be recorded?

After a short conversation with the customer, the reason for the request became clear. The customer was welding tanks with the Submerged Arc welding process, and they had a problem. They operate two sub arc welding heads, approximately 13’ apart, both of which need to be monitored for weld process quality. Their present monitoring solution used an operator sitting in a chair mounted to a ladder. The operator would move from one head to the other during the welding process in order to be able to see what was going on with both heads. During one of these shifts, an operator fell, and was injured. The customer’s initial solution was to replace the chair and ladder with a man lift to allow the operator to move between the weld heads, and welding controls when adjustments were required. But it still was not an ideal situation.

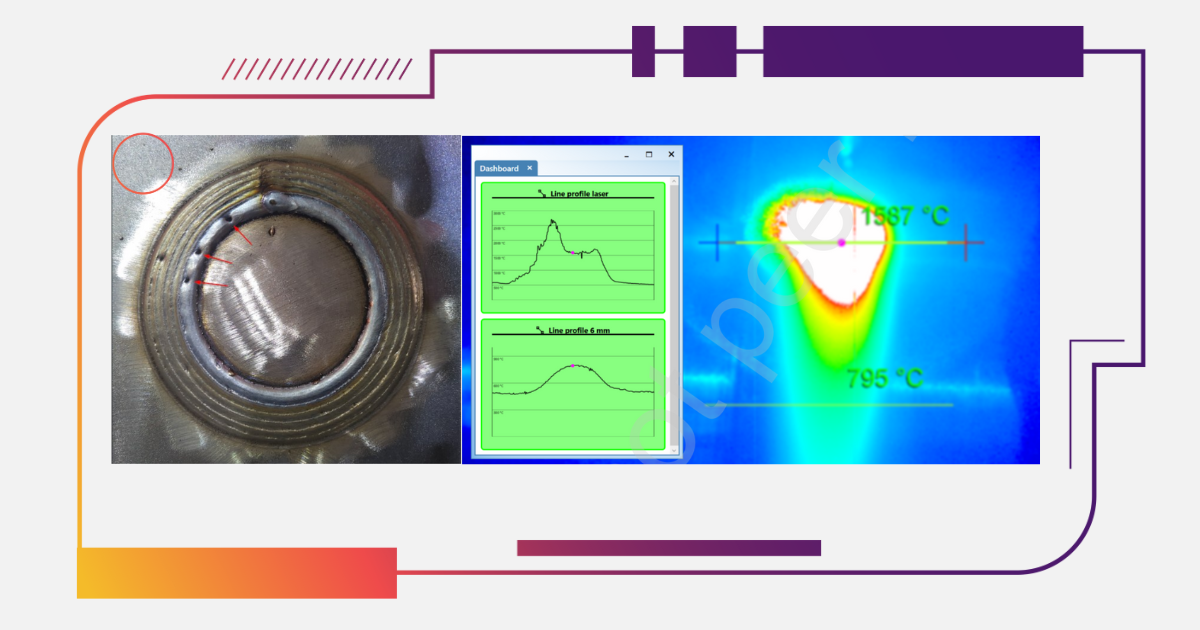

Instead, the customer wanted the operator to remain on the floor with the welding controls, monitor both welding heads, and perform the adjustments from there. The standard XVC-S View Camera system was designed for one primary camera, but has recently been updated.

The updated XVC-S+ system with multiple camera heads.

The XVC-S+ system, which comes complete with computer and HMI console allows for two cameras to connect to the console, and be displayed on a single screen in a split screen view. With this system, the operator is able to monitor both welding head images side by side on a single screen. With features such as adjustable crosshairs and targets on the screen, the operator is able to make continuous adjustments to the weld heads from a safe, remote operating location.

The images can be saved to the hard drive on the computer for off line viewing, review and analysis, allowing the customer to use the video segments for training, off line quality audits, and process troubleshooting.

In conclusion, a previously unsafe and inefficient welding environment resulted in injury and poor productivity. These problems were resolved with the addition of on system, the XVC-S+ Sub Arc View camera system including two cameras and split screen display capability.

.png)