The Xiris WI-2200/3000 Weld Inspection System is a weld bead and tube geometry measurement solution that is used to monitor key parameters that relate to process stability and tube or pipe quality. Adding a Xiris WI system to your mill provides real-time monitoring for multiple defect conditions, enabling continuous incremental improvements of mill quality and productivity.

The many measurements that the weld inspection system can provide are based on the differences between the actual laser profile line seen by the camera and the ideal mathematical profile. The diameter of the tube determines the length of the ideal profile line to be fit over the actual profile line. By knowing the position of the actual laser profile, the ideal profile, and the size of the pixels in the image, the WI-2200/3000 can calculate the various profile defects.

| Various Profile Defects: | |

| 1. Scarf Width 2. Scarf Depth 3. Scarf Defect 4. Deflection 5. Mismatch 6. Freeze Line |

7. Undercut 8. Left/Right Slope Angle 9. Bead Height 10. Bead Width 11. Bead Roll 12. Bead Ratio |

Over the next couple of months, we will be releasing a series of blogs expanding on the numerous profile defects that can be detected by explaining how they are detected and what it might mean for a mill process.

While most mill operators will use the weld inspection system directly after the weld box, some choose to place the inspection system after scarfing to check for quality issues related to the scarfing process. In this part of the series, we will be discussing such defects, the Scarf Width, Scarf Depth and Scarf Defect. Read on to learn more.

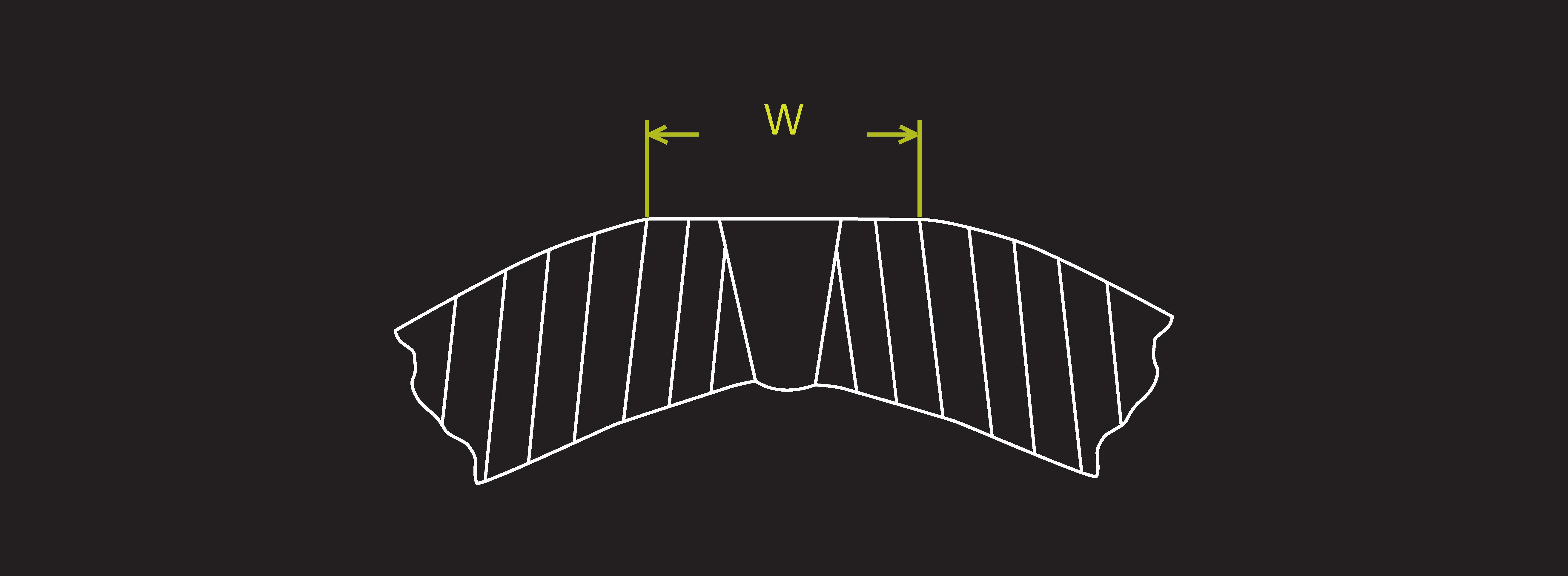

Scarf Width:

The Scarf Width measurement is taken after the scarfing tool and measures the size of the flat portion of the tube where the scarf has occurred. Sometimes, the Scarf Width can grow larger than desired if the scarf tool has been set to remove too much material, or the scarf tool has picked up too much dirt. For example, the support rollers used to hold the tube can get dirty with metal chips from the scarfing material and cause the tube to lift when debris gets caught between the roller and the tube. When this occurs, the tube gets pushed into the scarfing tool and as a result, removes too much material.

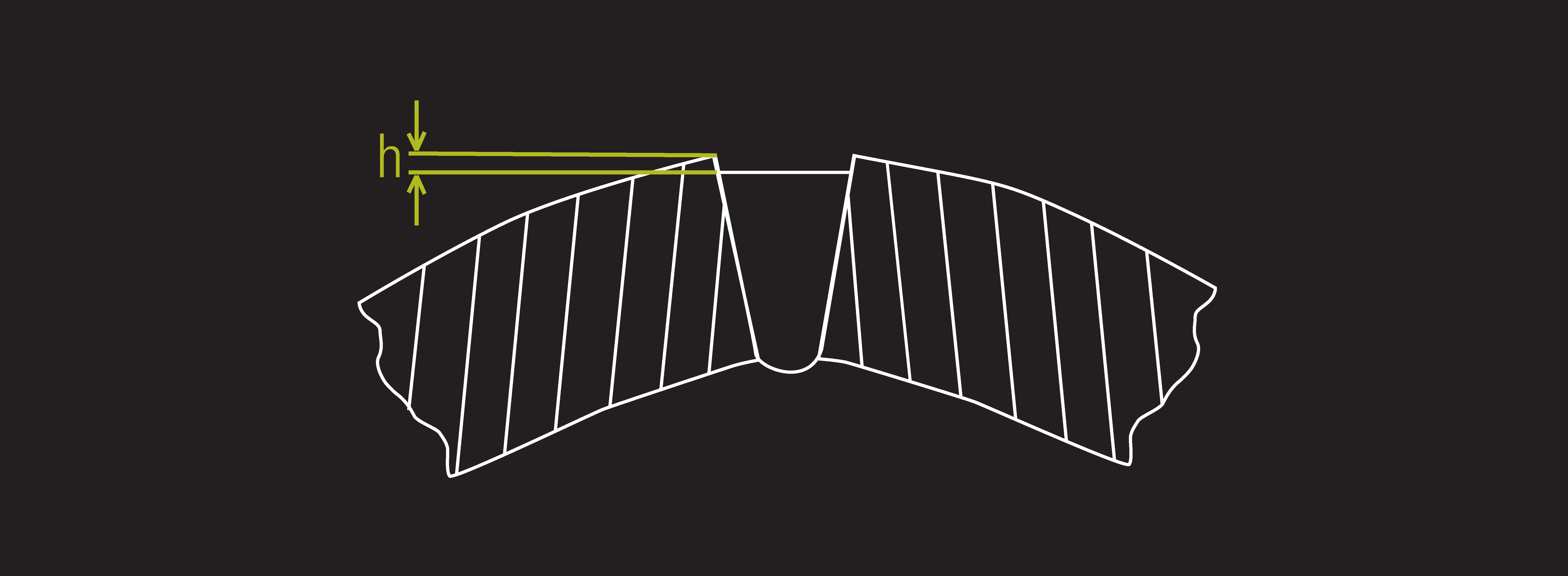

Scarf Depth:

An alternative to measuring the width of the scarf cut is to measure the depth of the scarfed surface as it can sometimes be below the desired surface of the edges of the parent material. Like the Scarf Width, this defect can occur if the scarf tool has not been properly set up to remove the right amount of weld bead, or if the tube unintentionally gets pushed into the scarfing tool due to debris. Debris on the supporting roller under the tube can occur on a periodic or random basis and can be difficult to detect with any other type of inspection process.

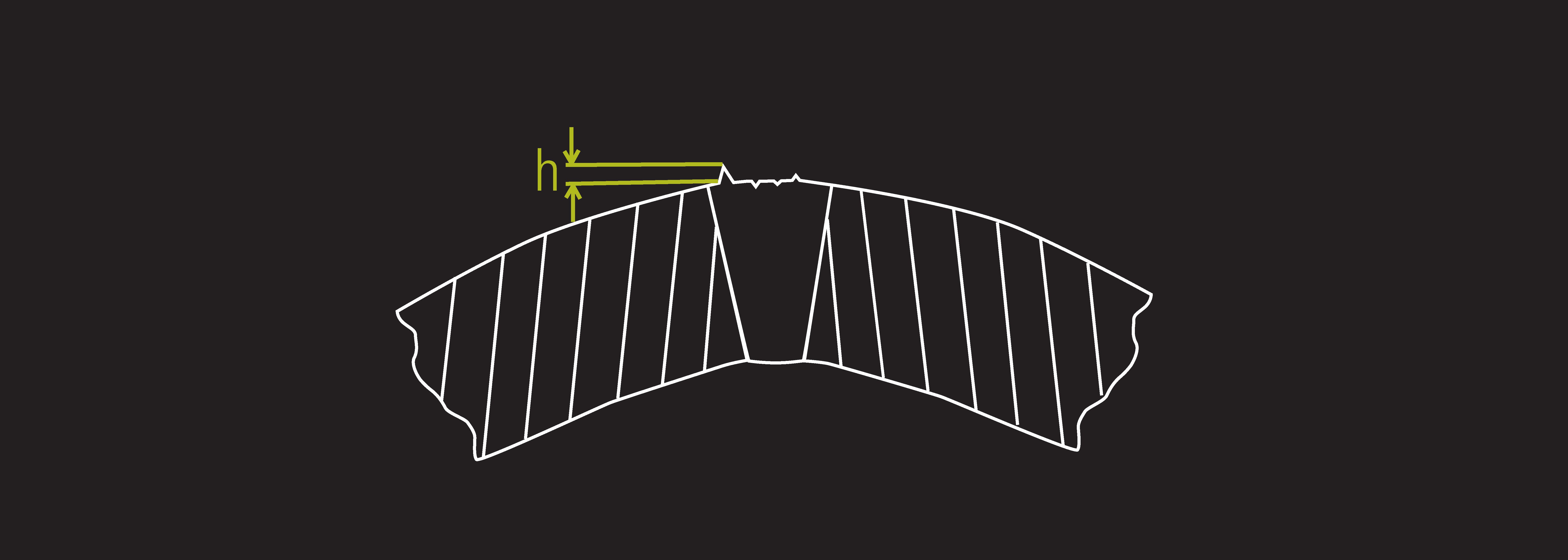

Scarf Defect:

The Scarf Defect measurement differs from the previous in that it measures the largest offset from a nominal surface as a way of indicating how non-smooth the scarfed surface of the tool is. A scarf tool is prone to eventually wear and may chip or even break over time. When this happens, the effectiveness of the scarfing process is reduced as the resulting scarf surface changes from a clean, smooth cut to a rough surface left with ridges from the damaged scarf tool.

When a defect warning or failure limit is breached, an audio and/or light tower signal can be sent. The condition can also be sent to a defect marking system (paint or laser) that marks the area of the product where the error occurred for further inspection, repair or removal.

Subscribe to the Xiris Blog to stay tuned on this series as we continue to explain the many remaining defect measurements that can be detected with a Xiris WI-2200/3000 Inspection System.

Stay up to date by following us on social media or subscribe to our blog!

.png)

.png)